In the beginning, there were tubes, in which a stream of electrons flowing through the near-vacuum space inside was controlled by voltage charges on metal plates and grids. Then there were solid state circuits. Many of us grew up with those buzz-words heralding anything that was purportedly "state of the art.

In the beginning, there were tubes, in which a stream of electrons flowing through the near-vacuum space inside was controlled by voltage charges on metal plates and grids.

Then there were solid state circuits. Many of us grew up with those buzz-words heralding anything that was purportedly “state of the art.” Solid state devices such as transistors control electrons as they flow through solid materials. A diode is perhaps the simplest solid state device, but even the most complex large-scale integrated circuits operate on the same principles.

You can make a radio by rectifying the radio frequency signal from a broadcasting station. Rectification is the conversion of ac to dc. In the case of a rapidly varying RF signal, a rectifier strips off the high frequency ac to leave a pulsating dc, which is varying at an audio frequency rate.

Actually, one of the first rectifiers was solid state; it was made out of a lead-sulfide crystal and a very thin wire called a “cat’s whisker.” The crystal was not a good conductor, nor was it an insulator. It was somewhere in between — a “semiconductor.” The point of the whisker was moved around the crystal until a junction was formed.

A “crystal” radio can even be built from a double edged razor blade and, believe it or not, a bent safety pin. With the point of the pin resting on the anodized part of the blade, the signal is rectified and can actually power sensitive earphones if you are close to a the station.

Today’s solid state diodes work the same way. They are formed by joining two similar, yet different semiconducting materials (Fig. 1). One material is termed the “N” type; the other the “P” type. The N-type material has a negative charge because its material has an excess of electrons. It is also relatively large — like the crystal or even the razor blade. The substrate in most semiconductors is silicon. However, some high-priced, high-performance and high-frequency semiconductors use gallium arsenide as a substrate. Makers of silicon-based semiconductors use arsenic and phosphorous as dopants to make N-type materials. They use boron as a dopant to make P-type materials.

Current flows in the N-type material in much the same way it flows in a wire; the excess electrons simply move through the material. The P-type material has a positive charge because it has “missing” electrons. It is relatively small like the “cat’s whisker.” The missing electrons form what some call “holes.” Current flows when electrons jump from hole to hole. Some say that the holes flow the opposite direction from the electrons. This is similar to a line of cars in a traffic jam. As each car moves forward, the next car moves up to fill the space left behind. An outside observer might say the spaces are moving backwards, but it’s really cars moving forward. The holes are merely the mechanism by which electrons can move in a P-type material.

Forming the PN junction

When the P-type material and the N-type material are joined together, a PN junction is formed. In the N-type material, only the electrons that are close enough to the junction with the P-type material to be attracted by the positive charge are able to cross over the junction and form what is called the “barrier region.” The rest of the excess electrons in the N-type material stay where they are, producing a net negative charge.

If we apply a negative voltage to the P-type material, the additional negative charge increases the size of the barrier region and makes it even more difficult to move electrons across the junction (Fig. 2). The impedance is very high and therefore does not allow significant current to flow. This is called a “reverse bias voltage.”

Applying a positive voltage to the P-type material, however, attracts more electrons across the junction and allows current to flow in the external circuit. The diode formed by the PN junction is now what is called “forward biased,” and has very low impedance (Fig. 3). The ratio between reverse biased impedance and forward biased impedance is at least 10:1 and can be many times higher.

A transistor has two of these PN junctions in series. The center material is very thin, and forms a barrier between the outer two materials. A transistor is made up of an emitter that emits electrons (or holes), a base that controls the flow and a collector that collects the electrons or holes. An NPN transistor has an emitter and a collector made of N-type material (Fig. 4). Again, the N-type emitter material has an excess of free electrons. The P-type material controls the flow of electrons from the emitter to the collector.

Just as it does in a diode, when the emitter-to-base junction is forward biased, current flows from the emitter, across the junction to the base (Fig. 5). With no connection to the collector, a small amount of base-to-collector current flows, just as in a diode.

If the base-collector junction has a large reverse bias (high positive voltage on the collector), the electrons that had migrated across the junction are attracted back to the collector, and the electrons that crossed into the base from the emitter see the high positive voltage on the collector and are also attracted to it. A small current still flows in the emitter-base circuit, but a much larger current flows in the collector circuit (Fig. 6). The small emitter-base bias “controls” a much larger emitter-collector current, thus providing amplification of the signal. The emitter current is the sum of the small base current and the larger collector current. The collector is made physically larger to accommodate the heat generated by the large current and to provide a large target for the free electrons in the base.

Reversing polarities

A PNP transistor is essentially the same thing with the polarities reversed. Just as in the previously discussed NPN transistor, a relatively small forward bias on the emitter-collector junction controls a larger current through the reverse-biased base-collector junction. The convention is to describe the current carriers in an NPN transistor as the electrons and the current carriers in a PNP transistor as the holes. Remembering, however, that the holes are merely spaces where an electron is missing and hole flow is in reality just electrons jumping from one hole to another. The mechanism is essentially the same in both types.

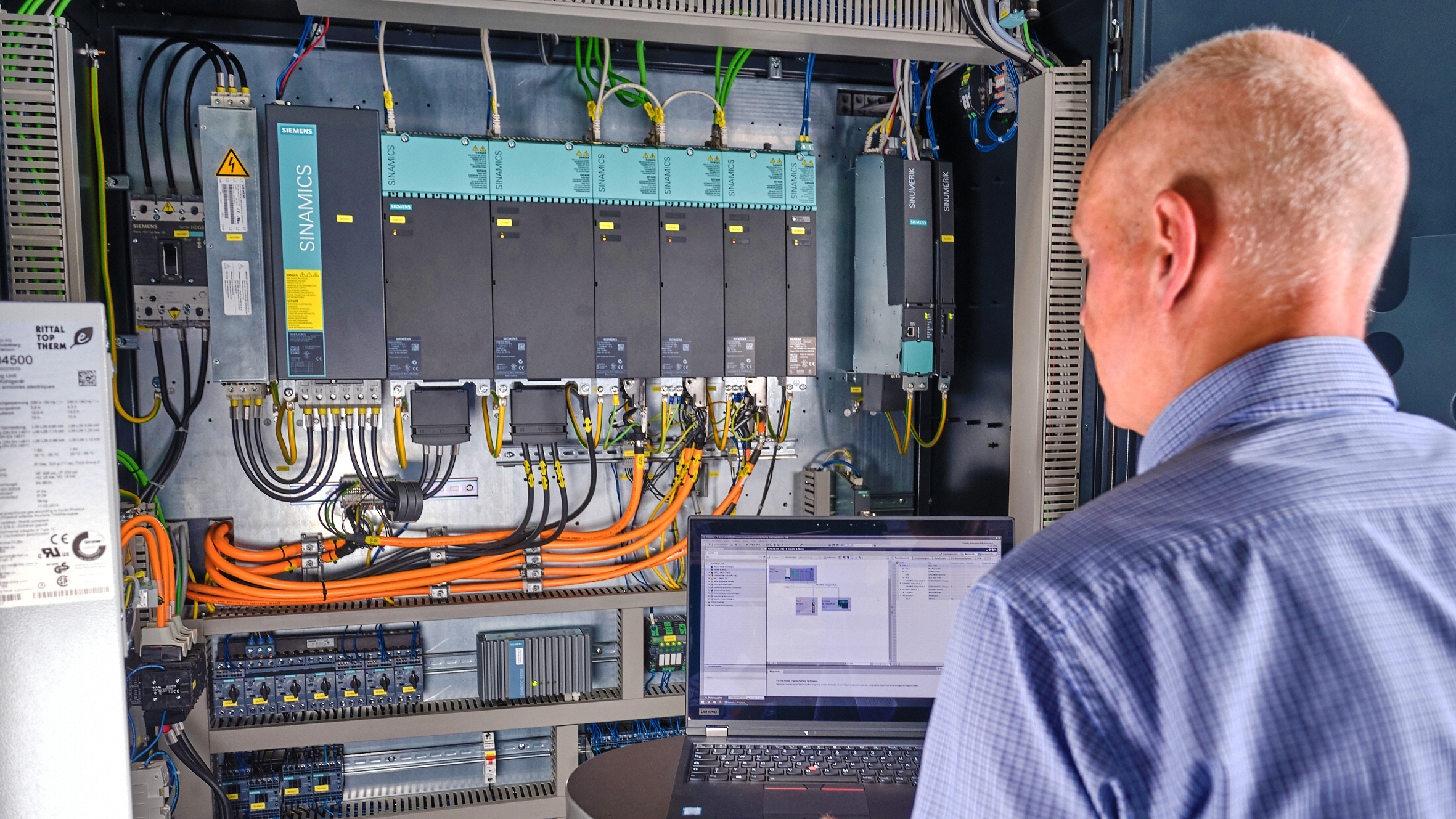

In this article, we have described simple diodes and transistors. However, there are many more variations on both themes. Small changes in mechanical arrangements, bias voltages and materials can make dedicated devices for regulation, impedance matching or high-frequency applications. The same basic theory applies to a small signal device in a cell phone and a high-power switch in a variable frequency motor drive.

The Bottom Line…

Semiconductors are neither pure conductor nor pure insulator; they are somewhere in between.

A semiconductor takes on either an N-type or a P-type characteristic, depending on the material used to dope the substrate.

Diodes are formed by joining N and P-type materials.

Transistors are formed by sandwiching one type of material between layers of the opposite type.

Fig. 1. P-type material contains a large concentration of holes with few electrons; N-type material contains a large concentration of electrons with few holes. A PN junction is formed when the two are joined. The holes from the P-side diffuse into the N-side, while the electrons from the N-side diffuse into the P-side. A negative space charge forms near the P-side and a positive space charge forms near the N-side of the junction. The net current flow across the junction is zero.

Fig. 2. When a negative voltage is applied to the P-type material, the junction is reverse-biased. This increases the size of the barrier region, which drives the impedance very high, making it more difficult to move electrons across the depletion zone of the junction.

Fig. 3. When a positive voltage is applied to the P-type material, the junction is forward-biased. This greatly decreases the size of the barrier region, which drives the impedance very low, and allows significantly more current to flow through the junction.

Fig. 4. A transistor is like a sandwich with the bread being the same type of material and the filling the other type. An NPN transistor has an emitter and a collector made of N-type material with a base made of P-type material.

Fig. 5. When the emitter-base junction is forward biased, there is current flow from the emitter to the base. If there is no connection to the collector, the base-collector current is small because that junction is reverse-biased.

Fig. 6. Placing a large reverse bias on the base-collector junction draws the current flow through the transistor. The relatively small emitter-base current controls a much larger emitter-collector current. When current flows through a load, such as a resistor, connected between the collector and emitter of the transistor, a voltage is developed that is an amplified version of what is applied between the base and emitter.

| Author Information |

| Wendell Rice has 25 years of experience as a controls engineer, and works for Parsons Technical Services. He can be reached at (765) 245-5357 or [email protected] . |

FEMP tags NEMA Premium motors

The Federal Energy Management Program has accepted NEMA’s recommendations for mandatory federal purchase of NEMA Premium motors in federal facilities.

FEMP issued federal notice of a new standard to all federal agencies on the procurement of Premium Efficient motors. The comments to the agency, jointly submitted by the American Council for an Energy Efficient Economy and NEMA, are the basis for the standard.

“Adoption of NEMA Premium by FEMP as the federal motors efficiency standard clearly signals our country’s willingness to save energy and reduce greenhouse gas emissions,” said Emerson Motor Company’s Rob Boteler, chairman of NEMA’s Motors and Generators Section Energy Management Task Force. “NEMA fully expects many industrial and commercial motors users to follow the federal example and specify only NEMA Premium motors.”

The new specifications are based on the efficiency criteria set by the NEMA Premium Efficiency Motors Program. For low-voltage motors up to 200 hp, the same FEMP and NEMA Premium efficiency criteria are also used by CEE’s Premium Efficiency Motors Initiative. FEMP has now extended the designation of premium-efficient motors to include medium-voltage electric motors (up to 5-kV) with rated capacities up to 500 hp.