Finding, training, and keeping skilled workers are serious problems facing every plant engineer. Maintaining an up-to-date skills-base has always been a challenge.

Finding, training, and keeping skilled workers are serious problems facing every plant engineer. Maintaining an up-to-date skills-base has always been a challenge. However, the situation has been made more critical today by our rapidly exploding technological environment.

One exciting tool emerging as a means for alleviating the training dilemma is the internet. The web offers an especially good mechanism for finding and reviewing training programs and educational materials. It also provides an excellent vehicle for delivering information and making interactive training programs available quickly, conveniently, and economically to large numbers of workers.

Back to school

Among an assortment of training offerings available are www.pe-training.net , a site you may already know. This online training provider for the plant engineering community is the combined effort of Plant Engineering magazine, Life Cycle Engineering, and Butterworth Heinemann. Two management classes have already been offered, with more in the planning. Features of this type of training approach include the flexibility to learn when you want, yet be able to interact with other professionals and the instructor.

We had the opportunity to review another noteworthy training effort recently. Sponsored by Dupont, www.virtual-workshops.com brings plant engineering, maintenance, and facilities management training to your plant site with live, technical, interactive workshops over the internet. With the aid of a site instructor, we toured a demo class to see the effectiveness of web-based classroom training.

Sessions are let by experts in the subject and provide real-time interaction among participants at any location. Workers can benefit from a two or three-hour seminar without leaving the job site. Requirements are simple: a PC and a phone line. Costs are determined by the number of connections; therefore, numerous employees may attend for a single fee.

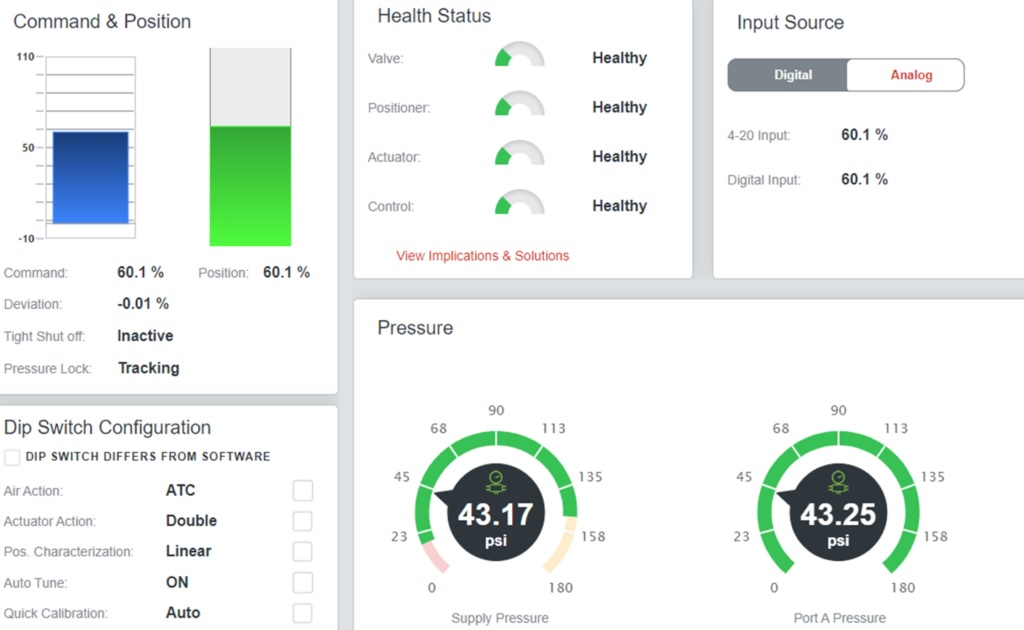

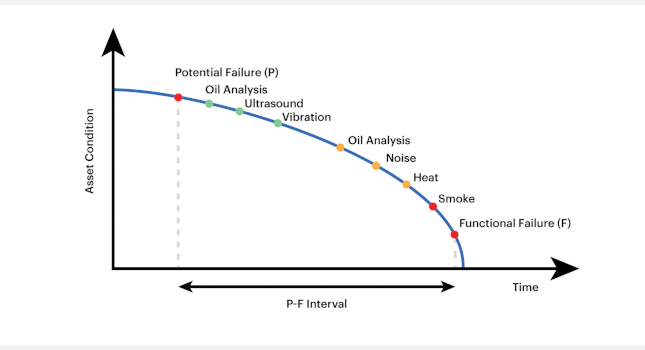

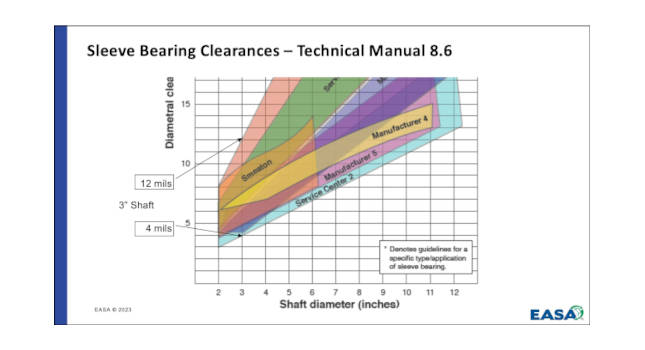

Topics presently on the class schedule include bearing failure analysis, benchmarking best practices in maintenance, control valve selection criteria, and more. An introduction to virtual workshops is available free for those interested in learning more about the process. For additional information, visit the site or call 302-999-4921.

e-Learning, e-Training

Here are a few more training-related sites that offer courses and classes for plant engineers.

www.iil.com (International Institute for Learning, Inc.) offers PC and web-based classroom training in project management skills. The site features a demo on its PM Basics program.

www.mpulsecmms.com (Mpulse Maintenance Software) presents live, interactive short courses on CMMS applications delivered to your desk over the internet.

Are you aware of other educational and training-related sites that would benefit plant engineering professionals? Please let us know . We’ll share interesting and informative contributions in future columns.