User experience (UX) research is a widely recognized approach for achieving comprehensive insight into a target audience, focusing on their behaviors, needs and expectations.

Learning Objectives

- Grasp the core principles and framework of user experience (UX) research.

- Recognize the importance of UX research in plant engineering applications.

- Acquire the knowledge and skills to implement UX research strategies in your role.

UX insights

- User experience (UX) research can be a vital element to the design and development of plant systems, platforms and products, ensuring that solutions are aligned with user requirements and provide an exceptional user experience.

- Plant engineering systems serve a diverse group of users, each with unique needs and challenges.

- System complexity and inefficiencies hinder workforce productivity, plant operations and overall company performance, resulting in a subpar UX.

User experience (UX) is a prevalent term within the tech industry, especially among innovators aiming to disrupt markets or outpace competitors. It describes people’s interactions with a product or service, encompassing design, functionality, accessibility and emotional response.

The importance of UX is deftly articulated by Bill Aulet in the first chapter of his book, “Disciplined Entrepreneurship, 24 Steps to a Successful Startup.” The book said, “The single necessary and sufficient condition for a business is a paying customer.”

Businesses attract paying customers by identifying their needs and delivering products or services that align with customer values and preferences. It is thus unsurprising that 18 out of the 24 steps to a successful startup focus directly on understanding and acquiring customers.

What does this have to do with plant engineering and work in manufacturing facilities? Interaction Design Foundation defines UX research as: “the systematic study of target users and their requirements, to add realistic contexts and insights to design processes”.

Let’s take this definition and think about it from a plant engineering perspective. Think about your manufacturing plant’s system and its numerous digital tools, software platforms and control systems. How many people interact with these various components daily? More importantly, how many people rely on them to effectively conduct their work obligations?

The likely answer to both questions — nearly everyone. Operators require accurate real-time data to make critical processing decisions, engineers use system information to design and model new plant features and executives must understand capacities and constraints to build a strategic vision for the company.

Now think about how many of these systems are easy to understand, use, troubleshoot and update? The likely answer — not many. Plant engineering systems are plagued with challenges including complex interfaces, perplexing integrations and data inconsistencies. These issues compound to make life difficult for everyone involved, from the plant floor to the boardroom.

We have the elements needed to effectively advocate for incorporating UX research strategies into plant engineering environments. Let’s review the fundamentals and discover how they can be applied to enhance systems and create user-centered applications.

UX research essentials

UX research aims to gain a deep understanding of the users who interact with a product or service. Its primary objectives are to gather actionable insights into the target audience, avoid errors stemming from unverified assumptions and ensure that product development remains closely aligned with user needs. This comprehensive data set is built through both qualitative and quantitative research techniques.

The two main kins of research, qualitative and quantitative, define how a problem should be approached.

Qualitative research focuses on the question — why do users behave the way they do? This approach is more open-ended and exploratory, clarifying user motivations, attitudes and experiences. It helps uncover underlying patterns and fosters collaboration across user groups. Examples include stakeholder interviews, useability testing and user observation.

Quantitative research examines the what, where and when of user problems and needs. Structured and data-driven, it allows researchers to collect measurable data that can be organized, categorized and analyzed using statistical methods, providing objective insights into user behaviors and trends. Examples include surveys, A/B testing and desirability studies.

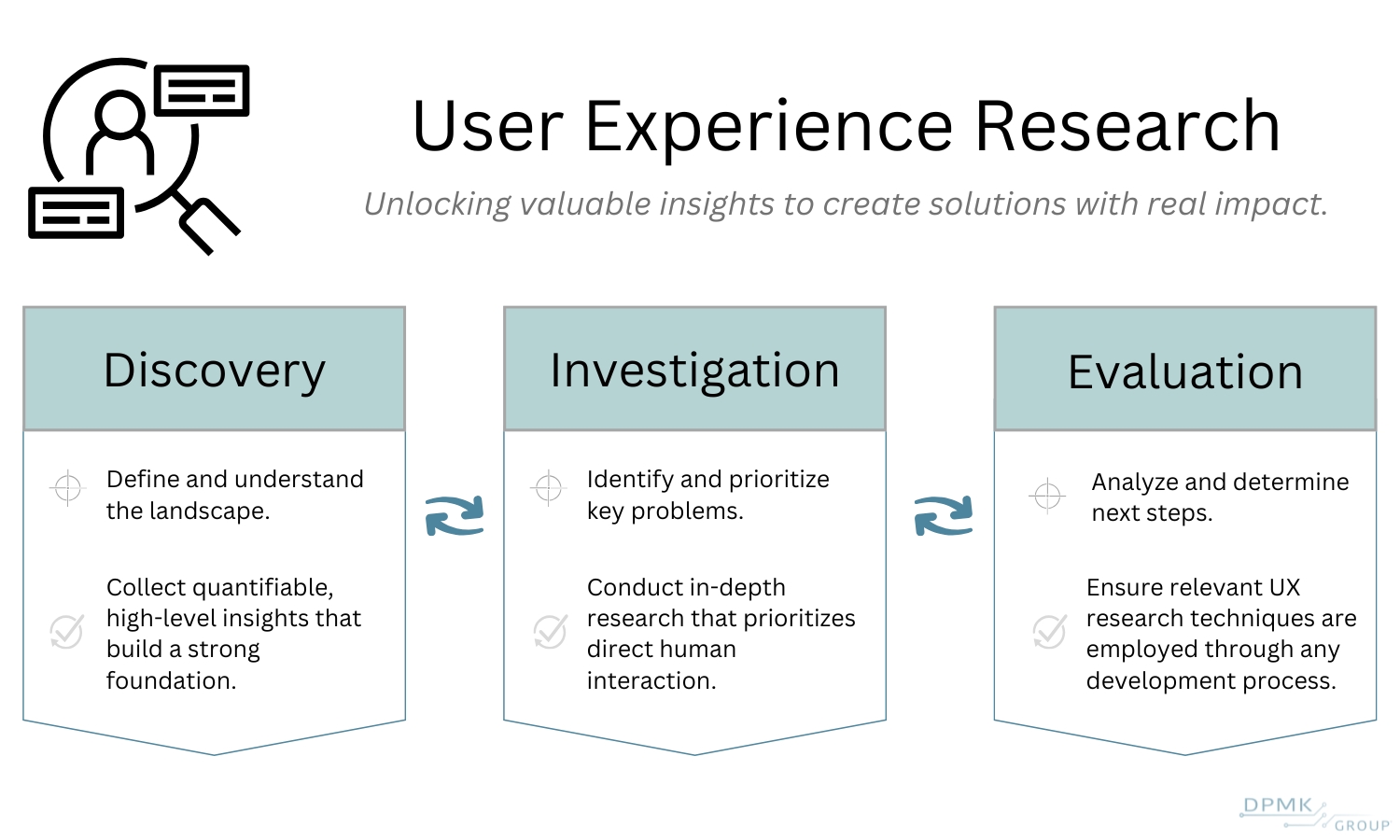

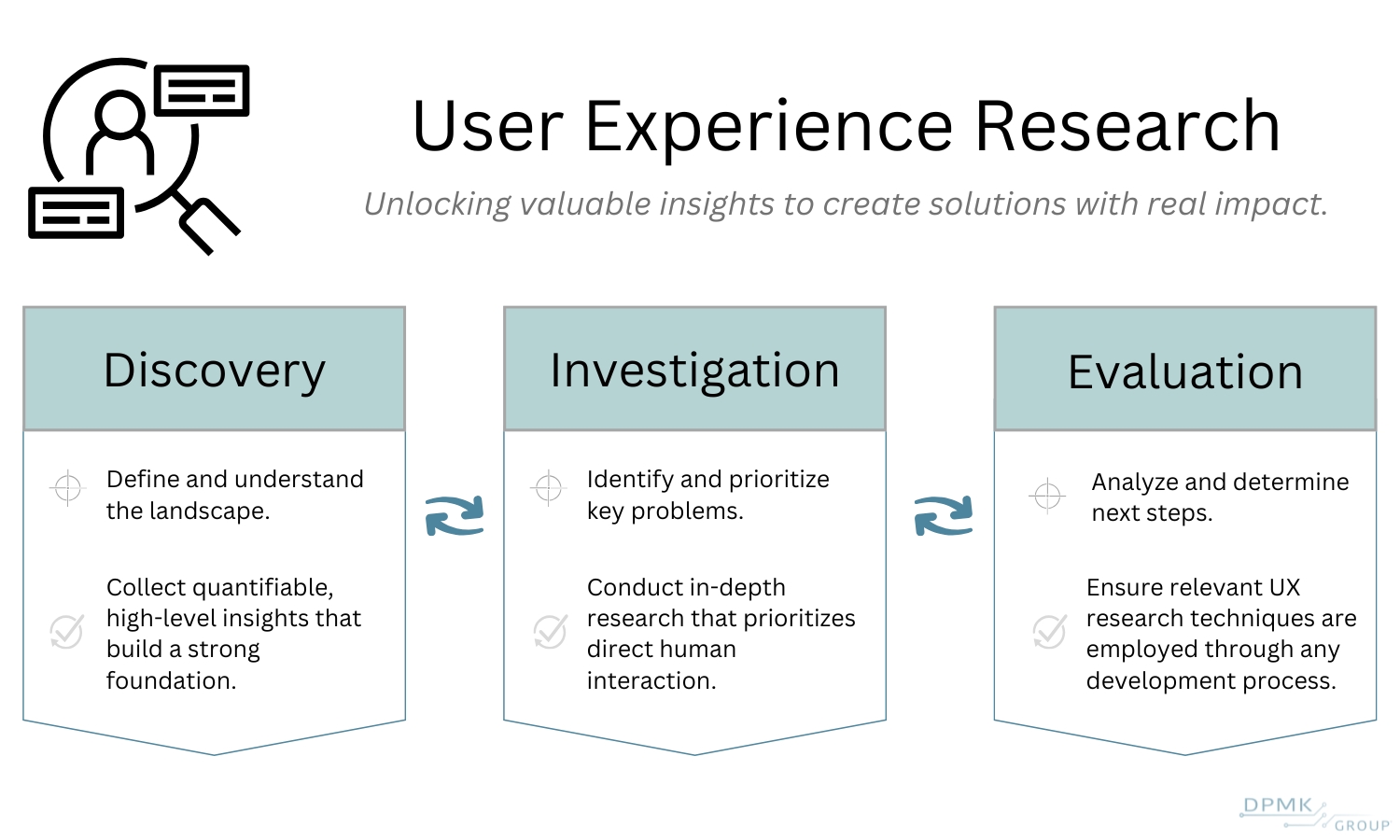

There are many established processes and strategies for applying both qualitative and quantitative techniques. Rather than focusing on terminology or semantics, it is advisable for readers to adopt a practical, common-sense approach. We typically organize this into three key components: discovery, investigation and evaluation (see Figure 2).

Here are a few practical tips for implementing these strategies and techniques:

Discovery

- Map all components: Identify and document all systems, platforms and tools that support plant operations.

- Organize stakeholders: Gather stakeholders from each department, outlining their roles, responsibilities and interdepartmental dependencies. Keep this high-level.

- Conduct a companywide survey: Design and implement a survey to evaluate the usability of the components documented. User input should be discreet, creating a standardized database for statistical analysis.

- Facilitate open-ended feedback: Allow users to provide brief open-ended feedback, limiting responses to a few sentences to maintain focus and avoid excessive detail.

Investigation

- Analyze discovery data: Leverage data from the discovery phase to identify key trends and metrics that will inform and guide subsequent actions.

- Create hypotheses: Begin defining and outlining potential problems, along with hypotheses and assumptions related to these issues, to be explored in follow-up discussions.

- Conduct user interviews: Interview a diverse range of users across teams and departments, from entry-level staff to management. Ensure interviews are structured while allowing space for candid feedback and elaboration.

- Engage in user observation: Organize and participate in user observations, particularly in dynamic areas. Shadow operators and maintenance personnel and attend relevant engineering or finance meetings. Focus on observing without interrupting, taking detailed notes instead.

Evaluation

- Create a comprehensive user data set: Develop a well-structured data set for all users, ensuring it is documented and stored for easy reference and updates.

- Maintain a process playbook: Establish a process playbook, tailored to your organization, to replicate and refine the UX research strategy.

- Determine next steps: Assess next actions and decide if further development is warranted. The UX data should greatly shape any subsequent product development.

- Gather UX data during development: If a product is developed, apply similar strategies to collect UX data throughout the development process, including user testing, feasibility studies for a minimally viable product and user interviews for feedback on features and design.

Case study: A food producer’s MRO problems

The DPMK Group team recently conducted UX research with a food producer’s maintenance and operations staff at a key location. The objective was to identify problem areas in their processing operations and provide recommendations for potential improvements.

The team began its research through a survey based on previous knowledge about the client’s operations. Results pointed to potential issues within maintenance operations, which led to complications such as poor machine health and interdepartmental inefficiencies. This quantitative data gave the consultants high-level information about the what, where and when. Further investigation using qualitative methods was required and done through interviews and user observation.

The team learned that the maintenance team was using pen-and-paper to keep track of inventory. Being that it was 2024, the lack of digital tools was obvious. The answer was not that something was missing, the producer’s in-house inventory management software was too difficult to use and lacked many basic features. Uptime was poor and it was not properly integrated with other systems. It took longer to use this clunky digital tool than to keep a logbook and manually update a spreadsheet to then email representatives in other departments.

Unsurprisingly, this pen-and-paper and spreadsheet method brought its own complications, resulting in erratic inventory management, wasted time, repair delays and increased costs. Often, maintenance-oriented shipments had to be rush-shipped and third-party contractors brought in on short notice to deal with emergency problems, leading to increased costs. Similar discussions with finance, purchasing and operations revealed that they too suffered from delays and frustrations.

The engineering team further divulged that this in-house maintenance program was itself difficult to maintain due to lack of documentation and an antiquated technology stack. Finally, a discussion with the corporate operations team unveiled frustrations with this particular location’s ability to manage and reduce maintenance costs. In short, it was a headache for everyone.

UX research continued to be a fundamental component as the project progressed, ensuring the solution would meet the needs of all users. As a next step, DPMK Group scoped out potential solutions and employed qualitative and quantitative research methods to validate key features. In doing so, the consultants discovered that an existing software provider offered a stand-alone maintenance management platform that was not only easy to use but also integrated seamlessly with the existing technology stack.

After careful consideration, the decision was made to choose this option as it was cost-effective and straightforward to implement and maintain. Stakeholders noted that the consistent user feedback and their active involvement significantly accelerated the project timeline while also reducing adoption and training time.

UX research: unlocking valuable insights

In summary, UX Research is a framework that offers a structured approach to exploring user trends, pain points and expectations. Understanding your target audience is essential for delivering products, features and services that meet their needs and encourage engagement.

UX research must incorporate both qualitative and quantitative techniques to ensure comprehensive data collection. Those new to the subject should consider adopting a discovery, investigation and evaluation framework that is well structured but also easy to follow, understand and execute.

Once adopted, many will realize that UX research is a vital tool for enhancing the development of systems and platforms, ensuring they align with user requirements and improve overall quality, especially in complex settings such as processing and manufacturing environments.