As control systems age and hardware and software reach end of life, manufacturers often find it difficult to justify and prioritize obsolescence upgrades until a failure occurs and the upgrade becomes an emergency.

Learning objectives

- Understand how to assess and prioritize obsolescence upgrade risks across a facility by evaluating systems criticality.

- Learn how to plan for upgrades through detailed preinstallation preparation, including constructability reviews, installation documentation and simulation/testing.

- Explore approaches for minimizing operational disruption and supporting organizational readiness including strategic scheduling, robust change management practices and repeatable upgrade processes.

Obsolescence upgrade insights

- Manufacturing teams can take a more proactive approach to obsolescence upgrades using a structured approach that involves assessing, planning and executing upgrades to minimize disruption and support long-term operational resilience.

- Obsolescence upgrades can become a reality for facilities by using best practices for getting started, properly planning and consistently executing upgrades with minimal disruption to production.

Aging control systems pose familiar risks to manufacturers — unplanned downtime, difficult-to-source parts, costly reactive repairs and the loss of original equipment manufacturer (OEM) support. Yet many manufacturers continue operating with hardware and software that has gone well past its intended lifespan often because obsolescence management feels overwhelming, hard to justify or low on the plant’s priority list.

But with the right approach, obsolescence upgrades and equipment modernization can be executed smoothly, strategically and with minimal disruption to production.

Begin with a risk-based assessment

While a facility likely has some visibility into which components are approaching end of life (EOL) or are already obsolete, it can be challenging to prioritize upgrades. One way to get started is to consider the business risks of continuing to run obsolete hardware and software including impacts to safety, uptime and supportability. Here are some questions to consider as the assess to help assess risk:

- What happens if a certain component fails? Will it halt a single line or bring down the entire plant?

- What is the current level of production downtime caused by obsolete hardware failure and what is the cost of that downtime? For example, lost production time multiplied by number of lost units multiplied by the sales cost per unit.

- How much effort is spent trying to source obsolete hardware through non-OEM channels?

- Would upgrading obsolete hardware enable other benefits such as yield improvements, better alarming, quality enhancements or a reduction in required changeover times?

At this point, a plant manager should also consider how making a change to one system may impact another. For instance, when upgrading a set of drives, the more modern drives might have Ethernet infrastructure requirements that the plant network infrastructure wasn’t designed to handle. If these types of dependencies aren’t identified early, an upgrade may not be successful.

Through the insights gathered from considering the answers to these questions, manufacturing teams can then develop a prioritized action plan for upgrades based on operational criticality and business impact.

Prioritize preinstallation planning and documentation

Once the need for an upgrade is well understood, successful execution depends heavily on upfront planning. Key steps include:

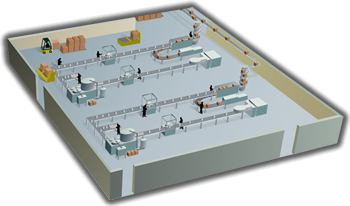

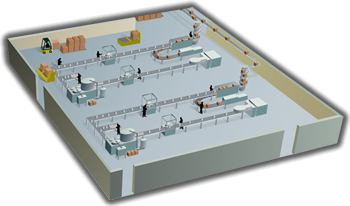

- Constructability reviews: Check that there are not any physical, spatial or logistical constraints on the plant floor that may impact the fit or function of the replacement equipment. For example, new hardware may have different physical dimensions or cooling requirements that need to be accounted for early.

- Installation documentation: Develop detailed drawings, clearly defined scopes of work and installation guides. These documents will provide contractors, installation crews, plant engineers and operations staff with the clarity needed to confidently execute the installation. Conversely, poor documentation can lead to delays, costly mistakes or even failed startups.

- Simulation and testing: Wherever possible, modifications to control system programming should be made in a nonproduction environment and tested in advance, such as using digital twins. Using simulation tools or developing in-office mockups can help validate system behavior, preventing many issues from ever reaching physical systems and equipment and minimizing surprises during commissioning.

Through detailed preinstallation planning and documentation, a plant can lay the groundwork for executing smooth and efficient upgrades.

Don’t overlook organizational readiness for obsolescence upgrades

Technology upgrades don’t exist in a vacuum; they impact everyone in the plant from operators to maintenance staff. Modernizing equipment often requires these employees to learn new skills, adopt new procedures or become familiar with new tools and requirements to successfully perform their jobs. This is why successful obsolescence upgrade and modernization projects must include an element of organizational change management, which needs to be considered from the beginning by engaging end users early in the planning process.

As upgrades come to fruition, practical hands-on training before installation and clear documentation covering all changes will help equip a teams with the tools they need to succeed. This is important because when operators and maintenance staff understand and feel confident in any changes made, upgrades are far more likely to deliver long-term value to the organization.

Minimize downtime through strategic scheduling

A common reason for deferring obsolescence upgrades is the inability for many manufacturers to have extended downtime. However, strategically planning for implementation can reduce or eliminate production disruption.

One strategy for doing this is to perform a phased installation. Upgrades can often be tackled in phases instead of all at once. For example, in plants operating multiple lines, each one can be upgraded individually so that production is never fully stopped. This approach also has the added benefit of allowing teams to bring lessons learned from the first implementation to improve subsequent phases.

Recently, Polytron took this approach to help a large grocery store chain modernize its commercial bakery’s flour handling process while minimizing downtime. The team developed a three-phase upgrade plan that aligned to the different areas of the facility’s flour delivery process. To further minimize downtime, Polytron also performed as much pre-work as possible including installing the new control panels, running conduit and conductors from the control panels to field devices and upgrading network connections all before taking the system offline.

Another strategy to minimize downtime when implementing obsolescence upgrades that can be used in conjunction with a multiphase approach is to align upgrades with existing downtime. Because many facilities have predictable shutdown periods for maintenance or seasonal slowdowns, by planning early, these windows can be leveraged to also complete obsolescence upgrades with minimal impact to production.

For a project to manage the planning and installation of new print-and-apply case labelers for a global leader in the production and distribution of nonalcoholic beverages, this was the approach Polytron took for many of the 33 packaging lines it upgraded. While this type of approach may require managing a lot of scheduling and logistics, it’s an excellent method for minimizing downtime, especially for facilities that produce perishable products that cannot really be stockpiled before a shutdown.

Lastly, scheduling should be based on a clear understanding of a plant’s operational cadence. Collaborating with production planners and plant leadership upfront can help prevent last-minute delays or resource constraints.

Expect and plan for the unexpected

Even the best-laid plans can hit unexpected roadblocks. Equipment may arrive late or break upon delivery, contractors can get reassigned or a weather event could postpone access to the site. While not everything can be completely planned for, resilient projects account for as many “surprises” as possible upfront through detailed contingency planning that might include:

- Keeping critical spare parts on hand

- Documenting wiring during removal to ensure reliable reinstallation

- Communicating potential risks and backup plans

As many manufacturers experienced, the global supply chain disruptions that resulted from the COVID-19 pandemic underscored just how vulnerable many projects are to certain external variables. And while proactive planning can’t prevent every delay, it can dramatically reduce the impact when things don’t go according to plan.

Build the next obsolescence upgrade on repeatable processes

Obsolescence upgrades and modernization projects are rarely one-time events because many manufacturers need to perform upgrades in stages across multiple lines or plants. Therefore, repeatability is essential. Standardized checklists, design templates, documentation formats and change management processes help teams work faster, maintain consistency and reduce errors. Additionally, continuous improvement, such as refining tools and processes after each engagement, can yield even greater benefits over time.

Even basic best practices — like labeling wires before disconnecting or taking photographs of panel layouts — can prevent issues during reconnection. These simple steps often distinguish well-executed projects from those that require costly troubleshooting during startup.

Because many manufacturers’ in-house engineers already have full workloads supporting daily operations and keeping production running, systematically executing obsolescence upgrades is often challenging. To further minimize risk and develop repeatable processes for performing obsolescence upgrades, it’s a good idea to form a relationship with a system integrator with both industry and technical expertise and experience managing and executing these types of projects.

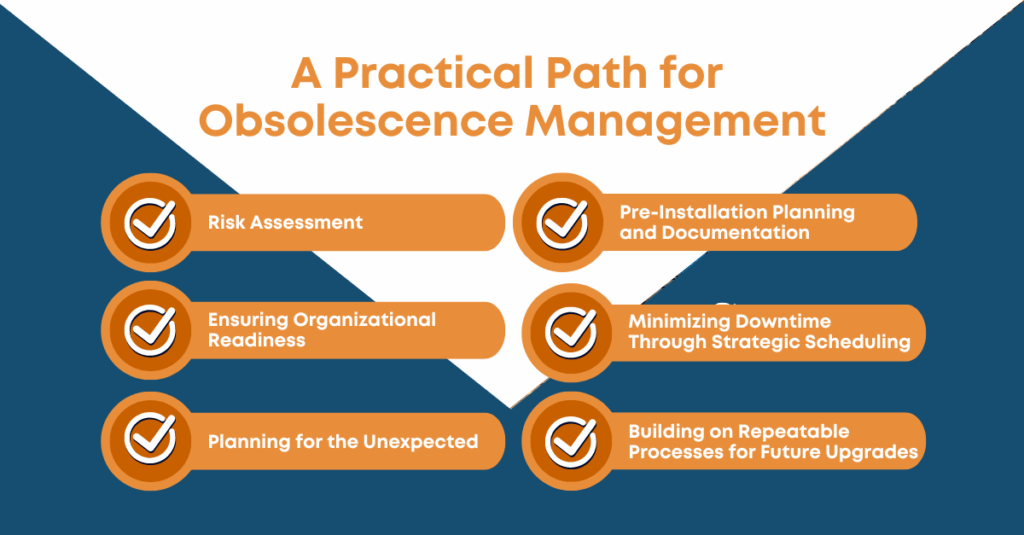

A practical path forward for obsolescence management

Obsolescence management and modernization projects don’t have to be daunting and reactive. When approached systematically — often with support from an experienced system integrator — obsolescence upgrades and modernization projects can strengthen operational resilience, reduce unplanned downtime and improve long-term supportability.

As discussed, the most effective strategies for managing obsolescence should include the following steps:

- Conducting a risk-based assessment of systems that are nearing their EOL or obsolete

- Performing thorough preinstallation planning

- Ensuring organizational readiness

- Developing clear documentation

- Scheduling upgrades strategically in phases or during planned downtime

- Planning upfront for potential disruptions or “surprises” during installation

- Leveraging standardized processes for long-term repeatability

To mitigate risk and make upgrades more manageable, a manufacturing plant must prioritize planning and implement with intention.