All companies should form solid customer relationships for success, but the field service industry faces more unique barriers to establishing a good word-of-mouth reputation.

All companies should form solid customer relationships for success. But the field service industry faces more unique barriers to establishing a good word of mouth reputation. Field service refers to company personnel resources (i.e. service technician) doing work at the client’s property, rather than the company’s property.

Some common field service industries are:

- Telecommunications

- HVAC

- Landscaping, construction and property maintenance

- In-home healthcare

Sending technicians to customer sites means lack of management oversight and communication, both with the back office and customers. For example, in a survey on field service satisfaction, 56% of customers said that their service techs arrived to them late, without providing an explanation. In field service, late arrival could be due to traffic delays or problems at a prior job. Customers already find late arrivals inconvenient, but even more so when delays aren’t communicated to them.

Some field service management operations include, but aren’t limited to: scheduling mobile technicians, tracking parts, and ensuring driver safety. Creating a good customer impression is challenging, but worth its weight in gold. The 2015 Forrester’s Customer Experience Index showed that improving customer experience by just 1% may increase revenue by $15 to 175 million. Consider implementing these three strategies to better serve your field service customers. Your reviews and your revenue have never been better!

Don’t keep customers waiting

Clients hate waiting for a long time for technicians to arrive, especially in emergencies. Unfortunately, it is quite common for field techs to give customers 8 hour ETA windows. With service scheduling software, managers can place service techs based on their distance from customers, which especially helps with appointment cancellations. Cloud based GPS can help field techs optimize their driving routes based on traffic and distance, which makes for timely arrival. By tracking distance to customer locations and predicting traffic delays, techs can also tell customers if they cannot arrive on time.

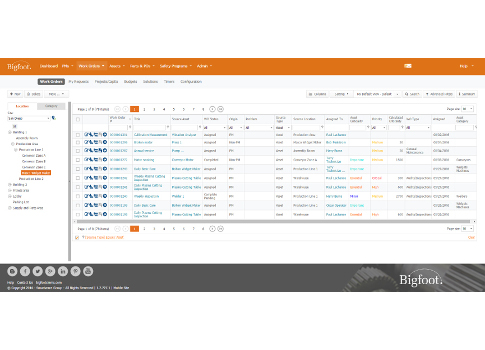

There are three forms of scheduling software: manual, semi-manual and automated. With manual systems, managers control and see where technicians are placed. Semi-manual can automate some tasks, but still require data entry. Manual systems may be time consuming for bigger, busier companies that can afford an automated scheduler that does all the work. But for the most part, all systems store employee skills, shifts, and location at any given time. Technicians can see their schedules offsite, which reduces their phone calls or visits back to the office. In the end, customers will be happier when service techs provide a more accurate ETA frame and let them know ahead of time when they’ll be late.

Get there before it breaks

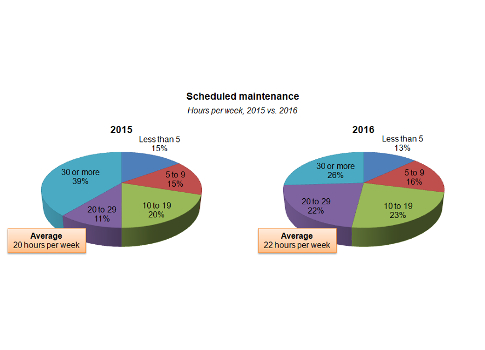

Preventing equipment problems from reoccurring or happening in the first place gives customers their money’s worth. Besides repair, service firms should offer maintenance services and be able to track parts that cause machine failure. Routine equipment maintenance services prevent minor issues from getting worse, which cuts long term repair costs on the customer’s end. These checkups also help customers interact better with service providers, which further improves business reviews.

The Internet of Things (IoT) is a key in preventative maintenance. Gartner predicts that in the next five years, over 25 billion devices will be connected to the IoT. Also known as connected devices, products with IoT technology track product use data (i.e. fuel levels, location, temperature). This helps companies learn more about their customers and help prevent product damage. In field service, IoT sensors can track power consumption and predict service outages before it’s too late. By knowing exactly when products need service, customers schedule maintenance and can avoid unnecessary appointments. Preventative maintenance ultimately helps he product last longer, which customers think very highly of.

Repair the product on the first visit

Aberdeen Group states that first time fix rate is a big key performance indicator (KPI) in field service. When faced with a product issue, customers want the problem fixed on the first visit. A low first time fix rate can indicate that there are many unhappy customers, which ultimately hurts revenue. One common problem in field service is that customers don’t always provide a detailed description of their problems on the phone. Then, field techs either revisit the office for product data or reschedule their visit to seek more information.

Cloud based field service software can easily help improve first time fix rates when strategically implemented. Trimble’s 2016 Insight report showed that companies that successfully implement field service technology finish up to 50% more jobs per week. With just a smartphone, field service service apps capture and store product serial numbers, barcodes, technical documents, photos, videos and other critical data. From the back office, Help Desk specialists can log customer issues onto this app, which field techs can access anywhere. By having instant access to data, service techs can arrive to customer sites on time and with all the info needed to solve the problem. Having all this data on a central system eliminates the need for paperwork, which also makes it easier to solve problems faster. And when an app integrates with the IoT, the company knows when a product needs service before the customer calls.

Mrinal Gokhale, content marketing, MSI Data. This article originally appeared on MSI Data’s website. MSI Data is a CFE Media content partner.