The importance of selective coordination as a strategy, and the dangers of ignoring such a strategy, were emphasized during PLANT ENGINEERING's Webcast on the topic May 25. The Webcast, sponsored by Cooper Bussmann, is one in a series of Webcasts planned this summer to focus on key safety and maintenance issues on the plant floor.

The importance of selective coordination as a strategy, and the dangers of ignoring such a strategy, were emphasized during PLANT ENGINEERING ‘s Webcast on the topic May 25. The Webcast, sponsored by Cooper Bussmann, is one in a series of Webcasts planned this summer to focus on key safety and maintenance issues on the plant floor.

Selective coordination involves localization of an overcurrent condition to restrict outages to the affected circuit or equipment, which is accomplished by the choice of overcurrent protective devices and their ratings or settings. Selective coordination is achieved when only the overcurrent device closest to an overload or fault operates to clear it.

Vince Saporita, vice-president of technical marketing and services at St. Louis-based Cooper Bussmann, and Charles J. Nochumson, application engineer for Eaton Electrical in Phoenix, provided examples of how to coordinate for optimum uptime and maximum safety.

“Selective coordination requirements increase system reliability,” Saporita said. “It facilitates power restoration to affected loads. It is vital for critical systems. It keeps critical loads powered as long and as much as possible.”

The Webcast covered the how as well as the why. “For fuses, we want the clearing energy for the load-side fuse to be less than the melting energy of the line-side fuse,” Saporita said. “In other words, if the smaller fuse clears the fault before the larger fuse melts, then there is selectivity between those two devices.”

“All the line-side emergency and legally-required protective devices in series with the downstream protective device directly protecting the circuit having the overcurrent must wait,” added Nochumson. “When progressing upstream toward the source, each protective device must be configured with an increasingly longer time delay. This will ensure the device downstream has an opportunity to operate and clear the overcurrent first.”

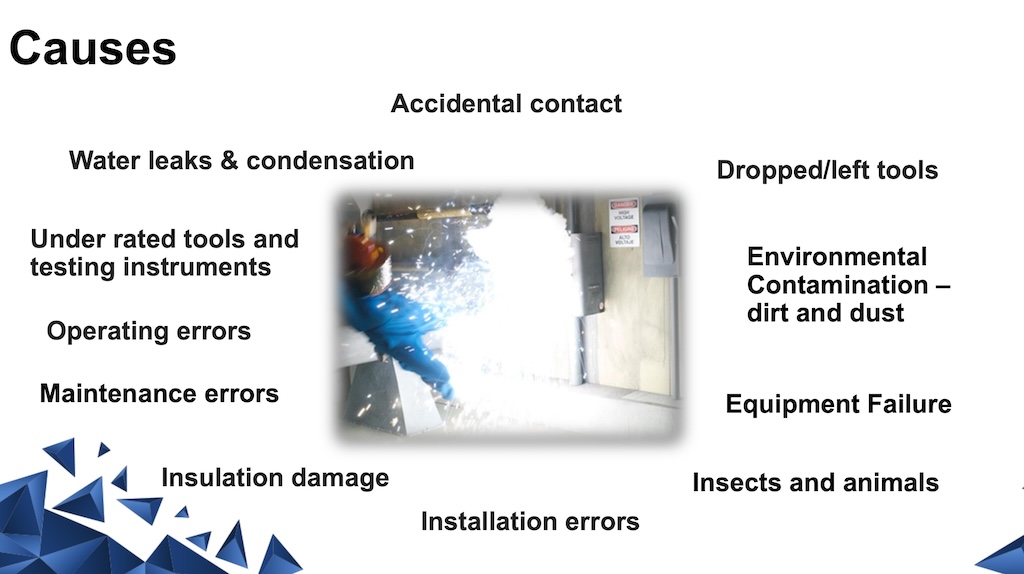

Both panelists offered best practices and electrical system design advice. They said caution should be used when designing selectively coordinated systems. “One of the consequences of increasing the size or type of overcurrent protective device to meet the 2005 NEC-mandated selective coordination requirements is that for the same level of fault current, the new protective device will wait longer to clear the same level of fault current,” said Nochumson. “If the fault is on the load side of the most downstream device, this is no problem.

“However, if the fault should occur on the line side of the immediate downstream protective device, such as when someone is working on an emergency panelboard hot — which is not recommended, but happens in the real world — and shorts the bus, then the available arc flash energy could be increased significantly.”

The “Selective Coordination Issues” Webcast is archived on the PLANT ENGINEERING Website. To view it, go to www.PlantEngineering.com , click on the “Plant Live” link, then on the “Webcast Archive” link.