Better parts visibility keeps the machinery of manufacturing running.

Looking at the way maintenance and parts inventories have evolved a more strategic approach to Enterprise Asset Management (EAM) in recent years, it is apparent that visibility is one of the most important drivers at every step in the process.

There was a time when the process for maintaining mission-critical equipment and replacing components when they failed was deceptively simple. The unit failed, or it began to perform so far outside expected parameters that it clearly needed attention. A maintenance team checked it and got it back in working order.

If they needed a part, they took it out of inventory. If there was no inventory in stock, they ordered it, and the repair was eventually done, whenever the part arrived.

For some companies, that is still the way things are done. (After all, they might say, it’s the way we’ve always done them.) But chances are, these companies do not enjoy the fact that their maintenance systems cost them more than they should—in more than one way.

It is more expensive to rush in a part on an urgent basis than to post a routine order. If an essential piece of equipment has failed, it can bring a whole line to a sudden, screeching halt until it is back up and running.

If your first inkling of a failing part is that a machine has stopped working, it probably means the unit has been sub-optimal for some time, slowing down or complicating the business process that depends on it. The final failure might even damage the equipment much more than if the initial problem had been caught sooner.

There was a time when a purely reactive approach to maintenance management was the only choice companies had. Those days are gone—great news for anyone who wants to run an efficient business or public sector organization.

New integrated EAM systems pay companies back by optimizing the efficiency and reliability of the core equipment and processes that managers depend on daily.

Visibility at every stage

The shift to EAM emphasizes visibility throughout the asset management universe.

Sensors monitor every step in a business process, every device or component it depends on, and issue real-time warnings when a piece of equipment falls outside its normal operating parameters.

The monitoring system quickly accumulates a mass of historical data that is more reliable and easily accessible than paper records, and much more effective at pinpointing the early signs of equipment stress and predicting failures before they occur.

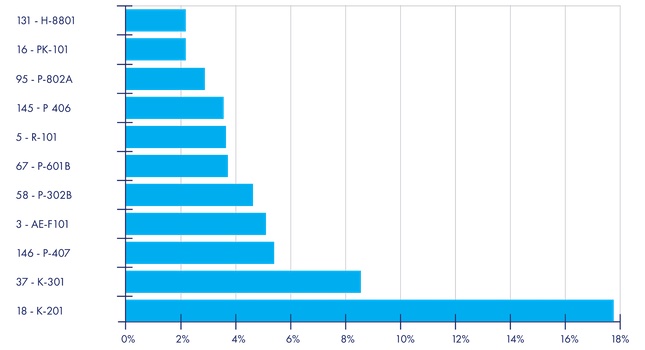

The user dashboards at the front end of the system deliver proactive alerts and key metrics and performance reports, providing the right level of tactical detail or aggregate analysis at different levels within an organization.

At its most basic, an EAM system does a better job of keeping track of what’s going on with the critical equipment and infrastructure a business depends on every day. However, its real power is demonstrated in the deployment of data to set targets, boosted efficiency, optimized distribution of equipment and maintenance personnel, and savings that go straight to the company’s bottom line.

Soaring to greater heights

As the Internet of Things (IoT) technology spreads through the modern production environment, the need for a strategic approach to asset management is soaring, and the benefits of adopting EAM are going into overdrive.

An integrated EAM system spots the problem, supports a timely response, triggers the purchasing system to replace spare parts before they’re needed again—then applies the decision to future challenges, becoming smarter all the time.

It’s a far cry from the paper-based systems that generations of plant engineers have had to settle for.

Kevin Price is the technical product evangelist and strategist for Infor.