In order to get management on board with IIoT, focus on the tangible business outcomes to make your case.

Is it possible to have an easier, less combative discussion with management when it comes to improving operational efficiencies at your manufacturing plant? If you want to prove that you can drive costs out of your organization in a timely manner with real, documented hard numbers, then the answer is yes. The backbone of that response is having an Industrial Internet of Things (IIoT) strategy in place.

IIoT is reaching new heights and never has its momentum been greater than in asset-intensive industries, especially when complemented by an enterprise asset management (EAM) system.

IIoT is not just the next come and go hot topic. It has staying power. It is a topic whose discussion that has a trickle-down effect from the boardroom to the plant floor, but more and more it is bubbling up directly from maintenance operations. From a maintenance department standpoint, it is a much different discussion and easier discussion with management than, “we want to upgrade or need to upgrade our enterprise resource planning (ERP) system or EAM system.” When presenting a well-conceived IIoT strategy, you won’t find yourself struggling with the traditional upgrade symptoms or pushback such as:

- No budget

- Limited executive support

- Data integrity issues

- Poorly-defined IT support roadmap

- Lack of resources

- A need for a better ROI to justify

- ‘If it’s not broke, don’t fix it’.

Instead, IIoT takes the discussion to a tangible business level with real use cases that can deliver that dreaded ROI. It also begins to address the human side of engineering, basically the knowledge gap that has been occurring with an aging and retiring workforce. With strong analytics and digital processes in place you can get more from the data you have, driving new insights to make better decisions rather than relying on basic work order tracking and labor reporting or picking the brain of your most seasoned veteran.

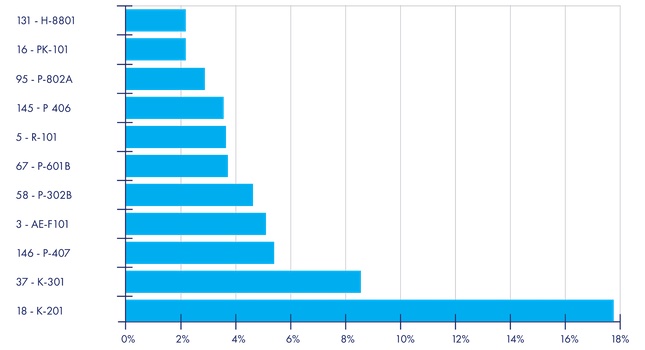

Many of you have already begun the process of implementing an IIoT strategy but just as many of you have yet to fully embrace it. The days of asking what happened (descriptive maintenance) and run to failure are long gone. The days of asking what could happen (predictive maintenance) and when should maintenance be performed has now been circumvented by asking what should we do (prescriptive maintenance) and what is the best avenue to pursue—how can we remove the guesswork?

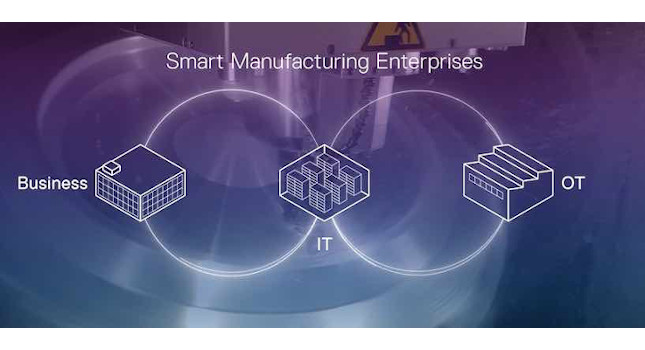

The time to accelerate your assets’ business value is now in such areas as optimizing asset utilization, reaching new heights in collecting and exchanging data, monitoring, managing and controlling connected devices, and governing your assets to prevent safety and regulatory risk. Information technology (IT) is becoming such an integral part of the product and production line with embedded sensors, processors, software, connectivity, and data residing in the cloud that it makes real sense to befriend your IT department. True teaming will be the norm. You may even find yourself asking whether the robotic arm on the production line is an IT asset or a plant asset.

Transitioning your organization to an IIoT strategy is a less cumbersome task than you may think. Start out small and get that first win, showcasing how your business gets stronger as you become more connected. This will propel you to a bigger IIoT play where many more get on board in understanding and advancing the intricacies of your assets to achieve unprecedented results. You can make maintenance relevant again. There really is nothing holding you back.

Ray Miciek, is executive vice president of sales and marketing for Aquitas Solutions.