Rather than trying to remove all vibration from the machinery, it is beneficial to seek to balance the machinery to the greatest extent possible.

The ultimate goal in any piece of equipment is to have it operating free of any vibration while running smoothly for a long time. In reality, however, vibration is always going to be a part of any rotating machinery, and certain levels of vibration may even be acceptable. Rather than trying to remove all vibration from the machinery, it is beneficial to seek to balance the machinery to the greatest extent possible. This reduces vibration to the point of reduced noise levels, and the existing vibration doesn’t affect machine life.

One method of balancing is known as static balancing, and it is achieved by using low friction bearings to allow the machinery to settle so that the heaviest point is on the bottom. It is then possible to remove material from the lower point or add it to the top point until it is rotating on the true axis. The process of static balancing is continually repeated until the heavy point no longer exists.

The problem with static balancing is that it can give a false correction, so the machinery is not truly balanced. Although this type of balancing may be perfectly acceptable on smaller machines, and it is a step in the right direction, using dynamic balancing is a much more effective way of removing vibration and extending the life of the machine.

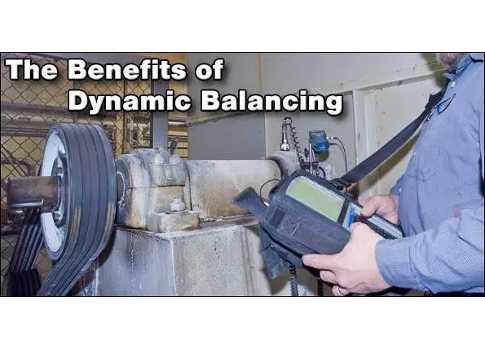

Dynamic balancing is performed with sensors attached to the bearing pedestals. It allows for the identification of the imbalance on two planes so that a real correction can take place. It makes use of machinery to identify the point of the imbalance and correct it. Other factors to consider are the length of the machine as well as its operating speed.

A problem with unbalance may be linked to various issues with the machine. These could include fabrication problems at the place of assembly, installation problems, and a machine that has been in service for an extended amount of time.

Benefits of dynamic balancing

When a machine is operating in balance, it is functioning as designed. Numerous consequences could result from having a machine in a smooth, well-balanced operating order. These outcomes include the following:

- Low vibration: One of the greatest sources of vibration is unbalance.

- Low noise: Mechanical vibration is also one of the leading causes of airborne noise.

- Operator fatigue: The exposure to high levels of noise and vibration can affect the efficiency of the operator.

- Operator safety: Machine failure is less likely to occur, personal safety is increased.

- Bearing life: Balancing the machine can extend the bearing life as it is affected most by unbalance.

- Structural stress: Due to the fact that vibration associated with unbalance is absorbed by the surrounding structure, having a machine operating in balance will reduce structural stress.

- Operating cost: Many facilities will keep extra machines on hand in case a breakdown occurs. Because machines operate longer and with fewer problems, you can keep fewer machines on hand.

- Productivity: The increase in uptime improves productivity.

Make sure that you include a vibration analysis in your preventative maintenance program. Not only can it help to identify a problem, it can often lead to a solution as to what can be done before a major failure occurs.

– David Manney is a marketing administrator at L&S Electric. This article originally appeared on L&S Electric Watts New Blog. L&S Electric Inc. is a CFE Media content partner.