Maintenance can be improved if companies focus more on improving their operations rather than maintaining what they have.

Can you imagine a football game where you don’t keep score? What if the coach doesn’t even go to the games? What if the players don’t know what position they’re in? We know that’s not the reality. The reality is, this happens all the time in manufacturing, said Mark Hungerford, director of customer services, Leading2Lean, during his presentation "Using Cloud Technology for Plant Floor Efficiency at West Liberty Foods" during Process Expo in September in Chicago. "People who need to know aren’t in the game," Hungerford told the audience. "They don’t have the information they need. They don’t know if they’re winning or losing."

Hungerford noted that "99% of the plants I go into are operating this way. Managers aren’t there or they receive the information late. We can’t imagine that in a professional football environment, so how do we avoid that on the plant floor?"

Maintenance hasn’t changed much, according to Hungerford. Many don’t see it as a value-added process. They’re out of sight, and they don’t know if they’re winning or losing. Technicians experience déjà vu as they fix the same problem over and over and they don’t know if they’re contributing to the problem.

Strength on both sides

The maintenance of the future, Hungerford said, will focus on improving and maintaining and being a critical part of the team along with production. Each has a clear role to play. Production needs to be a strong offense; maintenance a strong defense. And both sides, Hungerford said, need to learn from one another so they can help each other so they understand how each department’s actions improve the bottom line.

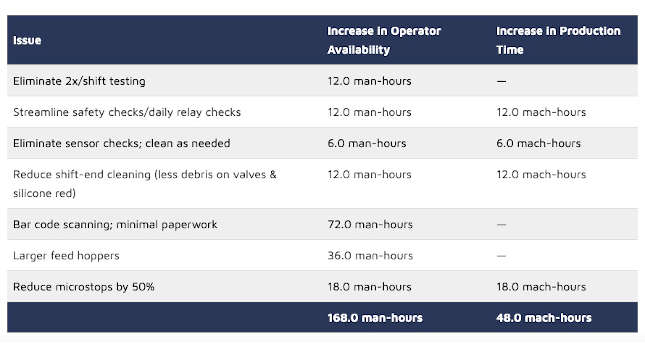

Maintenance of the future requires a different mindset in order to be successful. Technicians need to be engaged and contribute their creativity to improve the design of product equipment, processes, and overall efficiency. Instead of maintaining, workers should be giving them the tools and the expectation to improve.

"It’s time to eliminate the maintenance department replace it with the improvement department," Hungerford said. "Do we really want to just maintain?"

Four rules for winning the game

Companies that want to improve their overall efficiency can go from maintaining to improving through these four rules:

1. Visibility and transparency. Something everyone can score. Are we sliding back or are we just simply maintaining? The collected maintenance data is used by all and decision are made based on data rather than emotions. Transparency allows workers to see what works and what doesn’t as well as which departments or people are not carrying their weight.

2. Real-time visibility. "You need to be able to adjust in real-time during the game," Hungerford said. "If the offense isn’t working, they need to know now so they can make adjustments." This means there needs to be instant access to data and instructions and real-time communication through the various departments.

3. Make sure people have the right tools for tasks. The tools should compliment the process rather than burden it, Hungerford said. Gather data and information quickly and in real-time to solve problems. Real-time tools encourage real-time decision-making and they provide personal value to the user and to the company as a whole. Those tools, Hungerford said, have changed and mobile has become the new standard on the plant floor, which are designed to improve real-time decisions.

4. Focus on continuous improvement.

Companies that know they are good don’t just stop and rest on their laurels. Hungerford used an example related to Formula One pit stops. In the 1950’s, a pit stop took 67 seconds. In 2017, it takes less than two seconds. That’s continuous improvement, he said. Doing the small things right and learning from your mistakes, he said, are part of continuous improvement. And when a problem continues to come up, the worker needs to know how to problem-solve. That’s not always easy, he said, and it takes practices, but keeping at it will be beneficial in the long run.

Chris Vavra, production editor, CFE Media, [email protected].

ONLINE extra

See additional stories from Leading2Lean, a CFE Media content partner, linked below.