How an enclosures company, a computer maker, and a device supplier worked together to provide a plant-floor data center.

There are several official marketing themes at Hannover Messe 2018 in Germany—Connected Enterprise, Factory of the Future, and the ubiquitous Industrie 4.0. But a less visible theme is emerging as industry suppliers look to accelerate growth and deliver on the promise of the Industrial Internet of Things (IIoT): Good old-fashioned cooperation.

As big-name brands such as Microsoft, Intel, Oracle, and SAP try to make their presence felt in the industrial space, they are partnering with traditional manufacturing suppliers in some innovate solutions to allow not just a plug-and-play feel for the software, but a comprehensive solution for some of the hardware issues.

One good example is the partnership between device giant ABB, computer expert Hewlett Packard Enterprise, and enclosures leader Rittal. They announced the Secure Edge Data Center so manufacturers could locate their information technology (IT) assets on the plant floor and deliver secure and reliable data storage and management.

As the use of data continues to rise, more manufacturers are deciding between cloud computing for high-power enterprise analytics and the edge computing needs that will deliver fast sensor data to the plant floor in real time.

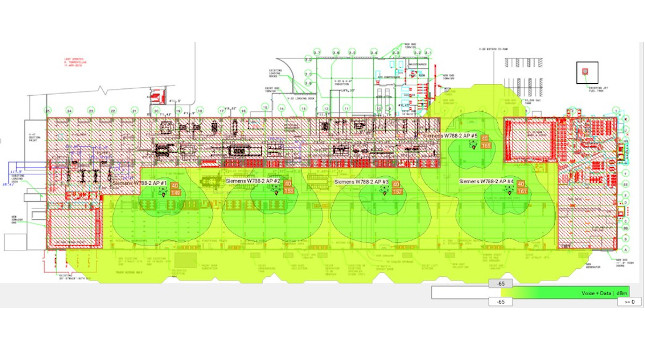

By contributing their individual areas of expertise to the solutions, ABB, Hewlett Packard and Secure Edge Data Center Rittal have created a secure box with fast computing and leading-edge sensor technology. According to a joint press release, the end product “provides a turnkey and resilient data center environment optimized to operate in harsh environments. It enables customers to run data acquisition, analytics and control processes near industrial equipment to avoid the latency, security and reliability issues associated with data communication through remote IT systems.”

The data center features a pre-configured Hewlett Packard software-defined infrastructure, an IP55-rated enclosure with integrated cooling and fire suppression from Rittal and redundant power supply from ABB with backup power, and remote monitoring.

New branding for a new show

There are always thousands of new products on display at Hannover Messe, but it’s also a great time to throw out a new brand identification. Bosch Rexroth’s familiar red logo has been upgraded to a wavy blue, grey and red look, and the company has been rebranded as Rexroth—A Bosch Company.

German-based LAPP has been seen as a cable company for decades but has repositioned itself beginning at Hannover Messe 2018 as a connected technologies company. Its new global brand, simply called LAPP, will cover not only the cable and connection business, but its expanded efforts in robotics, IIoT, and speciality products for the oil and gas and the food and beverage markets.

“Now is the right time to have a uniform name worldwide and a unified logo to link everything together,” said LAPP chairman Andreas Lapp in a press release. “Customers and their needs were at the heart of the decision. “These days it is no longer so important in which country our customers buy our products and where they are delivered to. We’ve been working as an international team for a long time. It is a logical progression for our external identity to reflect that. And what’s more that is exactly what our customers expect.”

Sweden is 2019 Partner Country

When Hannover Messe reconvenes on April 1-5 2019, Sweden will be the Partner Country.

"It is a great honor to be Partner Country next year. This will mean numerous opportunities for cooperation and exchange between Swedish and international companies,” said Peter Eriksson, Sweden’s Minister for Housing and Digital Development, at the signing ceremony during the 2018 show.

"Sweden’s government and industry are clearly committed to pursuing the digital transformation," said Dr. Jochen Köckler, chairman of the managing board at Deutsche Messe. "This makes Sweden a perfect match for Hannover Messe.”

Bob Vavra, content manager, Plant Engineering, CFE Media, [email protected].