The Industrial Internet of Things (IIoT) will spark a plant floor revolution. Here's how to get ready for it.

In the trenches of the Fourth Industrial Revolution, manufacturing is changing, one plant operation at a time. The crucial tool in affecting what experts suggest will be a seismic change in plant operations may be the one that workers bring with them to the plant every day.

A thumb.

The Industrial Internet of Things (IIoT) requires slicing and parsing the staggering volume of data collected through existing devices and those yet to be installed. New software systems are designed to analyze and organize the data into useful chunks for every worker on the plant floor. It’s all being delivered through new devices-tablets and smartphones and user-specific displays at workstations.

This Fourth Industrial Revolution also has spawned new terms: IIoT. Industrie 4.0 in Germany. Big Data. Digital Factory. The names may change, but the concepts converge around the same idea of connecting every part of the plant’s operation to each other, and to the people who manage those parts.

If it all seems equal bits of "Star Trek" and "The Matrix" with a dash of Willie Wonka, don’t be alarmed. Even the best of the IIoT experts concede we are just at the first stage of the process. Where we are headed, however, is clear. Strip away the whimsy and the uncertainty, and you are left with one fundamental truth: The Industrial Internet of Things will transform manufacturing.

The individual plant

One of IIoT’s most intriguing promises is that there is no one model for what IIoT can do for your plant. "Plant managers recognize that change is coming, but they have other priorities right now," said Richard Kelly, a partner in McKinsey & Co.’s North American digital manufacturing practice.

At the recent Smart Factory World Symposium sponsored by FORCAM in Cincinnati, Kelly said that IIoT "is going to force a change in strategic planning. It’s not about a one-off technology solution. It’s not like there’s a one-stop shop for technology solutions.

"Manufacturing silos, supply chain silos, IT (information technology) silos are collapsing," Kelly said. "There’s no one right answer here. The right answer is very company-specific: Where does value really get created in your company?"

"The biggest challenge for smaller companies is to make a decision on which direction you should go," said Wim Huijs, president of Enginetics Aerospace, at the FORCAM event. "For small companies, most of the time, you follow your customers." For small and mid-sized manufacturers, that means looking up the supply chain to see what larger players will need in an increasingly complex and individualized manufacturing process.

"When it’s all about making the widget and getting the widget out the door, where do they find the time and where do they find the capital (to change)?" asked Robert Sartin, co-chair of the automotive team at the law practice of Frost Brown Todd LLC in Cincinnati. "All the Tier 2 and Tier 3 companies are worried about is, ‘How do I pay my employees to get widgets out?’"

The answer may be in finding how IIoT can deliver repeatable results for the specific needs of the factory. Kelly said the factory of the future could be different models using the same technology to achieve different goals. One model would be a high-volume, automated plant to take advantage of economies of scale. Another plant could be focused on single lots, delivering a high level of customization using technology such as additive manufacturing.

But—and there’s always a "but"—Kelly pointed out the problem is not the data itself. Like Dorothy’s way back to Kansas in "The Wizard of Oz," the data always has been there all along and usually has been overlooked. "Today, 90% of data disappears. It goes nowhere," he said. "All the value you can gain is from the data that isn’t being used. You need to optimize the data you have before capturing more data."

The search for solutions

The success of IIoT is the development of software programs that find, capture, collate, and distribute data to plant personnel, and customize it so each person gets just what they need to be more productive. A maintenance worker doesn’t need the same information that a control engineer, a line worker, or the CFO might need from a given piece of machinery, yet that machine can produce data that each might need at some point.

The reason IIoT has so rapidly become a common term is that such programs are being developed today. Traditional manufacturing vendors are being joined by such companies as Apple, Cisco, Microsoft, SAP,and Verizon,for whom manufacturing was a small blip on abig radar. Those big names are attracting smallersolution providers who can create the programs and processes that will actually drive the connection between data and workers.

At a three-day event in suburban Chicago in June, SAP conducted a series of seminars focused solely on manufacturing issues around IIoT. The event’s Innovation Showcase featured more familiar names (Dell, Deloitte, IBM) and some less well-known companies focused on supplychain integration, enterprise product lifecycle management (PLM) solutions, and enterprise resource planning (ERP) systems.

At one session on reinventing manufacturing through IIoT, panelists focused on data capture and management, but also on the equally challenging issue of getting humans to connect at the same levels of speed and accuracy as the devices.

Tennant Co. is an early adopter of IIoT systems, dating back to 2009, and company CIO Paul Wellman noted at the SAP event that the challenge extended far beyond the technology to the traditional conflicts between information technology (IT) and operation technology (OT). "We were looking for more flexibility out of our operation in Pennsylvania and found that we could not make changes to operation in a timely fashion," he said. "We had to make sure this factory was flexible and able to meet the speed of business.

"There were culture shifts in IT and OT," Wellman said. "We had islands of data on the factory floor. The factory wasn’t connected. Once we connected the factory, we saw how we can leverage the data."

"It’s about how do we get these groups talking to each other," said Dave Gutshall, senior manager of manufacturing vertical solutions for Cisco. "It takes all levels of the organization. It can’t just be an executive conversation. It has to be on the factory floor. Ask your IT folks how much time they spend on the factory floor. There need to be change agents inside the factory floor."

Getting down to basics

In a press release announcing its new software suite to address IIoT and Internet of Things (IoT) programs, Cisco offered one of the more fundamentally sound explanations of where we are with all of this connectivity:

"Cisco estimates that 50 billion devices and objects will be connected to the Internet by 2020. Yet today, more than 99% percent of things in the physical world remain unconnected. To capitalize on the unprecedented opportunities presented by this wave of digitization, companies and cities are increasingly deploying IoT solutions. However, digitization is complex.

Customers are often connecting devices and objects-or converging unrelated networks—at previously unprecedented scales. Furthermore, they can only realize the value of these connections through the application of advanced data analytics; and, even then, customers often still need to create a new class of intelligent applications capable of accelerating new business models or increasing productivity. Of course, all of this has to happen without ever sacrificing security at any point in the system, from the device to the data center and via the cloud."

In an interview with Plant Engineering, Greg Gorbach, vice president for ARC Advisory Group’s IIoT business, said there are a number of daunting issues in the new age of IIoT. "Cyber-security threats are the biggest challenge, but many projects are moving forward despite this," Gorbach said. "Capital costs could potentially be a factor for small manufacturers, but that cuts both ways because IIoT also enables hybrid product-service models, where instead of buying an asset outright, the output of that asset can be had as a service, shifting the upfront capital cost into a recurring operating cost."

In that same interview with Plant Engineering, Karthik Sundaram, industry analyst for Frost & Sullivan’s industrial automation and process control business in Europe, suggests the challenges are real, but so is the potential. "IIoT has the potential to disrupt supply chains, increase production efficiency, expand customization capabilities, and reduce lead times significantly," he said. "A full-blown IIoT investment by a mid-size manufacturer can bring a minimum of a 30% increase in productivity and a 25% increase in financial gains, especially through optimized (operational expenses)."

Making it productive

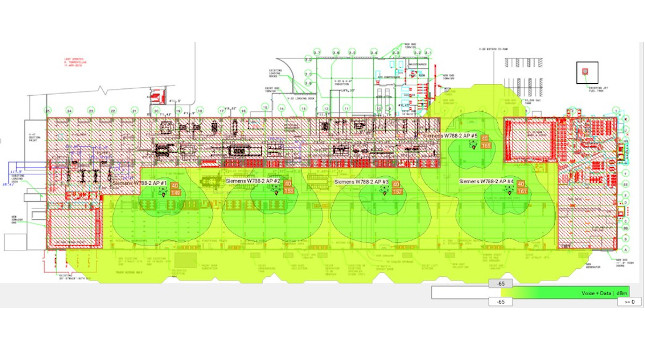

You don’t really need to install a new network to achieve such gains. Experts say you’ve simply got to better optimize the existing network of sensors and PLCs and SCADA systems. You can increase the number of connected devices, which will add more data and more complexity. The issue isn’t the complexity; it’s the data and how it gets used. Without a plan to use the data collected through IIoT to manage plant operations more effectively, IIoT could fail.

IIoT isn’t like an app that you select and implement," Gorbach said. "So the first thing a manager needs to do is become educated about the complexities involved. It can be daunting, but it doesn’t have to be."

Most experts agree that even with all the data captured in today’s pre-IIoT systems, only a fraction of it actually gets used to improve productivity or reduce waste. It is this challenge, above all others, that manufacturing faces as it stampedes toward IIoT adoption.

Robert Hust is co-chairman of Frost Brown Todd’s auto industry team. He’s also a former general counsel for Honda of America Manufacturing. He’s seen the potential and the pitfalls of information delivery up close. "The two points that are most relevant are transparency and traceability," Hust said. "There needs to be enough information for the employees on the plant floor, but not too much information. I think there’s a danger now that we not over-complicate the situation for the end customer."

Hust also sees the potential of IIoT for tracking parts and processes in the auto sector. "Traceability also is very important for the auto industry," he said. "It’s been an almost comically manual process. To the extent that these systems can improve traceability, that’s a good thing."

Getting plant floor workers better data is one challenge. Giving them the power to act on that data is another—but it’s an essential part of IIoT’s potential. "Who should make decisions on the plant floor? Everybody, depending on their role," said Yannick Schilly, vice president of operations at Festo Americas LLC, at the FORCAM event. "It’s important that the guy preparing the machine gets the information he needs, and that the maintenance guy can get the information he needs."

"It requires a realignment of roles and responsibilities," Hust added. "Organizations are going to have to have a clear idea on who can act on the data."

Connecting that data across not only the enterprise, but also across all plants within an organization also can create opportunities. "I can be sitting in one plant, and get information from any of the other nine plants," said Rangan Nandakumar, senior advisor for Cisco Systems. "This will help me support plants worldwide. It also can help in decision making."

"Standardization is one of my big strategies," said Robert Smith, director of continuous improvement and industrial strategies for GKN Aerospace. "I want each of our facilities to have the same thing, to see the same thing."

Smith sees the potential benefits of IIoT, but only if plants simultaneously flatten the management structure and give more responsibility to plant floor workers. IIoT will work best, Smith said, "When workers understand what they know is important and what they have is important. If you don’t support your people on the floor, you’re not going to get what you need.

"There’s no greater wealth in a manufacturing company than what’s going on at the plant-floor level," Smith added. "If my employees understand what’s going on, that makes them intelligent." It’s a sentiment echoed by Franz Gruber, FORCAM’s founder and chairman. "We’re now empowering individuals as never before," Gruber said in his keynote at the FORCAM event.

"We’re forcing the transformation of corporations from command-and-control models to flatter, more collaborative ways of organizing. The two sides of the coin are technology and organizational leadership. What (IIoT) is doing is forcing us to re-imagine the operation. I strongly believe the CEO and director of manufacturing need to be evangelists."

All thumbs—in a good way

So with the distribution of data through IIoT, more people will get more data that is more focused on their exact job functions, delivered through remote devices. Their whole world will be in their hands.

Which brings us back to thumbs.

The changing roles in manufacturing come at a time when manufacturing is transitioning from a labor-driven process to an information-driven process. New workers coming into that kind of plant will have different skills, including a comfort with the tablets and smartphones that current workers may not possess.

Or to put it another way: "All millennials are very good with their thumbs," said Wim Huijs of Enginetics Aerospace. He said that will be important because, "instead of just feeding data to shop floors, now we have to get information back from the shop floor."

Angela Buckley, operational-excellence manager for ThyssenKrupp Bilstein in Hamilton, Ohio, said the challenge is to move forward without leaving anyone behind. "It’s not just the technology, but how you roll this out to the people," she said. "While the millennials are really great with their thumbs, we run the risk of alienating those who have been with us for years." The challenge, said Buckley, is how to make it cool. "I started in the foundry. It was not cool and not clean and I was scolded for logging into my computer on my first day."

That’s going to change with the next generation of workers, and for the workers transitioning into the world of IIoT. "They’re coming out and expecting you to be up to speed," Buckley said. "Guys in the shop have kept up with current technologies, and they are open to the new technologies that younger people are bringing to the plant."

The plant’s data infrastructure must also be up to the task. "They’re going to ask about things like how fast is your login process and how secure is your wireless," said Buckley. "If you give them a cell phone that flips open, they’re going to work on their own cell phone, whether you think that’s secure or not."

So the Fourth Industrial Revolution will depend on digits, but it also will depend on adaptability. Plant owners will have to adapt in the same way, and at the same pace, as plant managers and plant workers. It will require investment in time and training and process. Despite all the growth in manufacturing over the past decade, it will not be enough to simply go along as usual. Change is coming, and those who can’t or won’t change will be left behind.

"Industrial systems are about to undergo a significant and disruptive change," Gorbach said. "This will lead to innovations in business models and in the way companies compete. Existing plants and factories have, for the most part, fallen well behind the technology curve—but a number of them are starting to do something about it."