Plant Engineering's 2016 Salary Survey shows optimism amongst manufacturers remain strong going into 2017, but there are some concerns about the future and they don't know what the Industrial Internet of Things' (IIoT) role will be in the workplace.

We have a tendency to get caught looking backward or forward. We expect that history will be instructive and that by learning from that history, the future will be better. While an analysis of where we’ve been and where we’re going are excellent tools in business or in life, it is wholly appropriate to stop at times and do a clear assessment of where we are today.

Plant Engineering’s 2016 Salary Survey is one such opportunity. With American manufacturing squarely in the spotlight as a new administration takes office in Washington, the data gathered from this year’s survey of Plant Engineering’s readers shows a solid foundation from which to continue manufacturing’s eight-year regrowth after the 2008 recession.

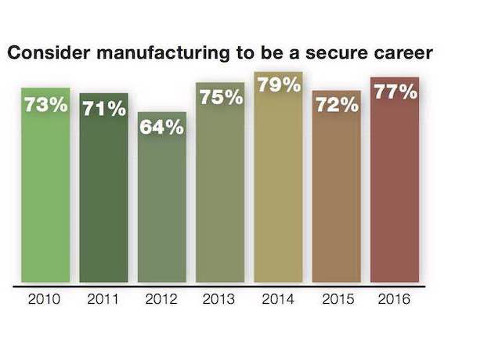

Optimism about manufacturing as a career has seldom been higher; 77% of readers say it is a secure career. The economy remains the leading challenge facing manufacturers, and many of our readers in their verbatim comments cited the lack of willingness for their own companies to reinvest in plants as a significant concern. The things that plant management controls at a local level-investment, skilled workers and competition-ranked ahead of taxes, government regulations and outsourcing as concerns on the plant floor.

Compensation also evolved in 2016. While salaries rose a healthy 3% in the year, bonus compensation fell, and the net result was a flat average salary from 2015 to 2016. In some of the more labor-intensive industries, such as oil and gas production, food and beverage, and metals, bonus compensations remained relatively high. In industries such as electronics, appliances and machinery, bonuses dwindled.

The only area of bonus compensation that grew in 2016 was company profitability. Other bonus criteria, including safety, productivity, cost reduction and quality, all declined in 2016. This past year was the first time since 2011 that average bonus compensation fell below $10,000. We’d prefer to consider this a statistical anomaly rather than a trend. Manufacturing is expected to drive further growth in the new year, and workers and plant managers will help drive that growth.

An important part of that growth will be the integration of new technology, specifically the Industrial Internet of Things (IIoT). For the second year, we polled readers about the impact of IIoT on their operations. While there is a greater incorporation of IIoT into manufacturing, nearly 50% still are unsure how IIoT will benefit their operation and most see it only as a tool to better manage data and maintenance.

While most facilities have a mature or developing maintenance program, 8% still have yet to implement such a program. The news is much better on the safety side: 88% of plant managers describe their safety program as mature or developing. Even as we stop to view a snapshot of manufacturing as it is today, we recognize that technology and a changing world mean that this snapshot will quickly become a reference tool. Nonetheless, we hope the 2016 Salary Survey offers our readers a solid foundation to evaluate where each facility is in relation to their peers, and a shared commitment to continue to look to a better future.

ONLINE extra

Learn more about the 2016 Salary Survey’s findings in the Plant Engineering digital edition below.

2016 Salary Survey findings: Who We Are

2016 Salary Survey findings: What We Earn

2016 Salary Survey findings: What We Think

2016 Salary Survey findings: What We Think: IIoT

2016 Salary Survey findings: What We Think: Asset Management

Bob Vavra, content manager, Plant Engineering, CFE Media, [email protected].