While much media attention has been focused on extending battery operating life through the use of low-power chipsets and communication protocols, the potential energy savings gained from all of these schemes fails to compare with the energy lost to annual self-discharge.

Remote wireless devices used in industrial automation and the Industrial Internet of Things (IIoT) increasingly require the use of long-life lithium batteries to ensure reliable performance and to reduce the total cost of ownership.

Powering these devices with industrial-grade lithium batteries can eliminate the need for hard-wiring devices to the power grid, which is prohibitively expensive, costing roughly $100/ft for any type of hard-wired device, even a basic electrical switch. These costs can rise exponentially in hard-to-access locations.

If a remote wireless device draws an average current in microamps, it typically can be powered for extended periods using an industrial-grade primary (non-rechargeable) lithium battery. If the device draws an average current in milliamps, then it may be better suited for some type of energy harvesting device in conjunction with a Lithium-ion (Li-ion) rechargeable battery to store the harvested energy.

Lithium thionyl chloride batteries last longer

Lithium batteries feature a high intrinsic negative potential that exceeds all other metals. As the lightest non-gaseous metal, lithium offers the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all available battery chemistries. Lithium cells operate within a normal operating current voltage (OCV) range of 2.7 to 3.6 V. These chemistries also are nonaqueous, making them less likely to freeze in extreme temperatures.

Numerous primary lithium chemistries are commercially available, including iron disulfate (LiFeS2), lithium manganese dioxide (LiMnO2), lithium thionyl chloride (LiSOCl2) and lithium metal-oxide. Of all these alternatives, LiSOCl2 chemistry is preferred for long-term deployments involving extreme environments, including AMR/AMI metering, machine-to-machine (M2M), supervisory control and data acquisition (SCADA), tank-level monitoring, asset tracking and environmental sensors, to name a few.

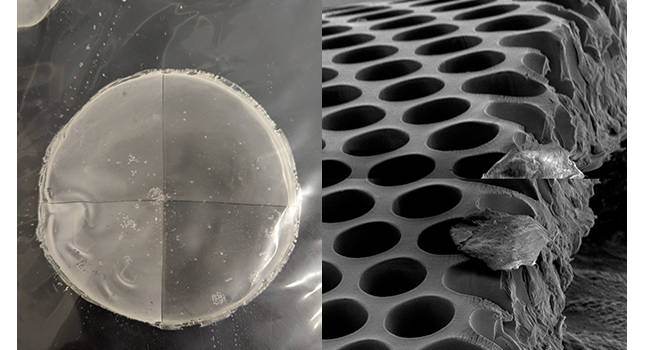

Bobbin-type LiSOCl2 batteries feature the highest capacity and highest energy density of any lithium battery, which supports product miniaturization. These batteries also feature a low annual self-discharge rate (under 1% per year for certain cells), permitting up to 40-year battery life. Bobbin-type LiSOCl2 batteries also offer the widest possible temperature range (-80 to 125 C), and are made with a superior glass-to-metal hermetic seal that resists leakage (see Figure 1).

Specially modified bobbin-type LiSOCl2 batteries are used in the cold chain to continuously monitor the transport of frozen foods, pharmaceuticals, tissue samples and transplant organs at -80 C. Bobbin-type LiSOCl2 batteries also are uniquely adaptable to high temperatures. For example, these batteries power active RFID tags that track the location and status of medical equipment without having to remove the battery prior to autoclave sterilization, where temperatures can reach 125 C (see Figure 2).

Lower self-discharge is crucial

While much media attention has been focused on extending battery operating life through the use of low-power chipsets and communication protocols, the potential energy savings gained from all of these schemes fails to compare with the energy lost to annual self-discharge.

Self-discharge is a natural phenomenon that affects all batteries, as chemical reactions occur even when the battery is in storage and not being used. Self-discharge rates vary based on a number of factors, including the current discharge potential of the cell based on its design, the purity and quality of the raw materials and the ability of the battery manufacturer to control cell passivation, thereby slowing down the chemical reactions that lead to self-discharge.

Understanding passivation

Passivation is a thin film of lithium chloride (LiCl) that forms on the surface of the lithium anode, creating a high resistance layer between the electrodes, thereby restricting the chemical reactions that cause self-discharge. When a load is placed on the cell, the passivation layer causes higher resistance, which can cause the cell’s voltage to dip temporarily until the discharge reaction slowly removes the passivation layer. This process repeats itself each time the load is removed.

Different factors can influence the amount of passivation, including the current capacity of the cell, length of storage, storage temperature, discharge temperature and prior discharge conditions, as partially discharging a cell and then removing the load increases the amount of passivation relative to when the cell was new.

Better batteries balance passivation and energy discharge

Passivation is essential for reducing battery self-discharge, but too much of it can restrict energy from flowing when its needed most. Conversely, less passivation permits a greater rate of energy flow, but the tradeoff is a higher self-discharge rate and a shorter operating life.

Comparing the effect of passivation on self-discharge and energy flow is like comparing bottles of fluid with different size openings (see Figures 3 – 7 and Figure 9):

- The volume of the glass/bottle is equivalent to battery capacity

- Evaporation/self-discharge is equivalent to capacity loss

- Flow volume is equal to discharge/energy flow

- Low liquid/electrolyte quality can cause the opening to get plugged up, which can cause flow stoppage/passivation

- Low liquid/electrolyte quality can cause evaporation/self-discharge

- Bobbin-type LiSOCl2 batteries have very “small openings”

- LiMnO2 and alkaline batteries have “larger openings” that permit higher flow rates but also result in faster evaporation/self-discharge

- Large openings are good for fast flow/discharge but not for storing fluids for a long time

- For long operating life you need a small opening for low evaporation/self-discharge

- Opening size/battery design is a critical issue – too large an opening can cause too much evaporation/self-discharge; too small an opening and there is no flow and the opening can be clogged (passivation)

- Fluid/chemistry quality is imperative to keeping impurities/passivation low.

How to deliver low self-discharge and high flow/pulses

Remote wireless devices increasingly require periodic high pulses to power two-way wireless communications and other advanced functionality. These requirements invariably draw additional current, so various methods are used to conserve energy, including low-power communications protocols (ZigBee, WirelessHART, LoRa, etc.), low-power microprocessors and more efficient data sampling and transmission.

Standard bobbin-type LiSOCl2 batteries are not designed to deliver high pulses due to their low rate design. However, this can be solved easily by using a patented hybrid layer capacitor (HLC). The standard bobbin-type LiSOCl2 cell delivers low daily background current while the HLC handles periodic high pulses. The patented HLC also features a special end-of-life voltage plateau that can be interpreted to deliver automatic low-battery status alerts (see Figure 8).

Figure 6: Volume left after 10 and 20 years of self-discharge only (no load): XOL TL-49xx Series (a); IXTRA TL-59xx Series and other manufacturers, generally not recommended for applications requiring more than 10 years of operating life where the average daily current drawn to operate the device plus the annual self-discharge rate will deplete cell capacity to a point so low that it compromises long-term reliability (b); LiMnO2 and alkaline cells, high annual self-discharge rates make 10+year battery life impossible (c). Courtesy: Tadiran Batteries[/caption]

Testing for annual self-discharge can be misleading

The long-term impact of a battery with a higher self-discharge rate may not become apparent for years, and theoretical methods for predicting actual battery life generally under-represent the importance of the passivation effect along with long-term exposure to extreme temperatures.

Figure 8: PulsesPlus batteries combine a standard bobbin-type LiSOCl2 battery with a patented hybrid layer capacitor (HLC) to deliver the periodic high pulses required for two-way wireless communications. Courtesy: Tadiran Batteries[/caption]

For example, accurate long-term test data is essential to specifying batteries for AMR/AMI utility meter transmitters, as a large-scale battery failure can disrupt customer billing systems and disable remote service start-up and shut-off capabilities. The city of Springfield, Mass., learned this lesson the hard way, as the municipality was forced to begin prematurely replacing thousands of water meter batteries each year to avoid the potential of a mass disruption to its automated billing systems (see Figure 10).

Further considerations

When specifying an industrial-grade lithium battery, various technical requirements should be factored in, including: the amount of current consumed in active mode (along with the size, duration and frequency of pulses); energy consumed in standby or sleep mode (the base current); storage time (as normal self-discharge during storage diminishes capacity); expected temperatures (including during storage and in-field operation); equipment cut-off voltage (as battery capacity is exhausted, or in extreme temperatures, voltage can drop to a point too low for the sensor to operate); and the annual self-discharge rate of the battery (which can approach the amount of current drawn from average daily use).

A top-quality bobbin-type LiSOCl2 battery can enable certain low power devices to operate for up to 40 years, achieving a low cost of ownership due to a very low annual self-discharge rate.

When calculating your projected cost of ownership, make sure to include all anticipated expenses, including future battery replacements over the lifetime of the device, as well as calculating the added costs and risks associated with premature battery failure.

When extended battery life is essential, remember that theoretical claims regarding battery life are often misleading by failing to properly measure the passivation effect and energy losses caused by long-term exposure to extreme temperatures. So, do your due diligence.

Sol Jacobs is vice president and general manager, Tadiran Batteries.

This article appears in the Applied Automation supplement for Control Engineering and Plant Engineering.