The transition of NFPA 70B from a recommended practice to a standard is changing how organizations approach electrical safety. This shift supports a proactive safety culture, reducing workplace accidents and enhancing worker confidence through standardized maintenance protocols.

NFPA 70B insights

- NFPA 70B plays a critical role in electrical safety by establishing proactive maintenance practices that prevent equipment failures and reduce hazards like arc flashes, complementing OSHA 29 CFR 1910.147’s lockout/tagout requirements to control hazardous energy.

- Integrating NFPA 70B’s maintenance guidelines with OSHA’s energy isolation standards is essential for preventing deadly workplace incidents and ensuring compliance.

Electrical exposure is a serious risk. Over the past decade, 1,500 workers have lost their lives to preventable electrical incidents, many linked to equipment failure or uncontrolled energy.

In 2022, 147 people died from electrical exposure, according to the Bureau of Labor Statistics (BLS). These figures show the importance of both NFPA 70B: Standard for Electrical Equipment Maintenance and the Occupational Safety and Health Administration’s (OSHA) 29 CFR 1910.147, its federal regulation for the control of hazardous energy, which together tackle maintenance and energy isolation to safeguard workers.

NFPA 70B is a comprehensive standard for maintaining electrical equipment, outlining practices to prevent failures and mitigate hazards like fires or shocks. OSHA 29 CFR 1910.147 mandates specific procedures to control hazardous energy during maintenance, ensuring equipment is safely de-energized before work begins. Together, these standards create synergy. NFPA 70B’s focus on proactive maintenance complements OSHA’s energy isolation requirements, reducing risks such as electrical shocks and arc flashes that threaten workers daily.

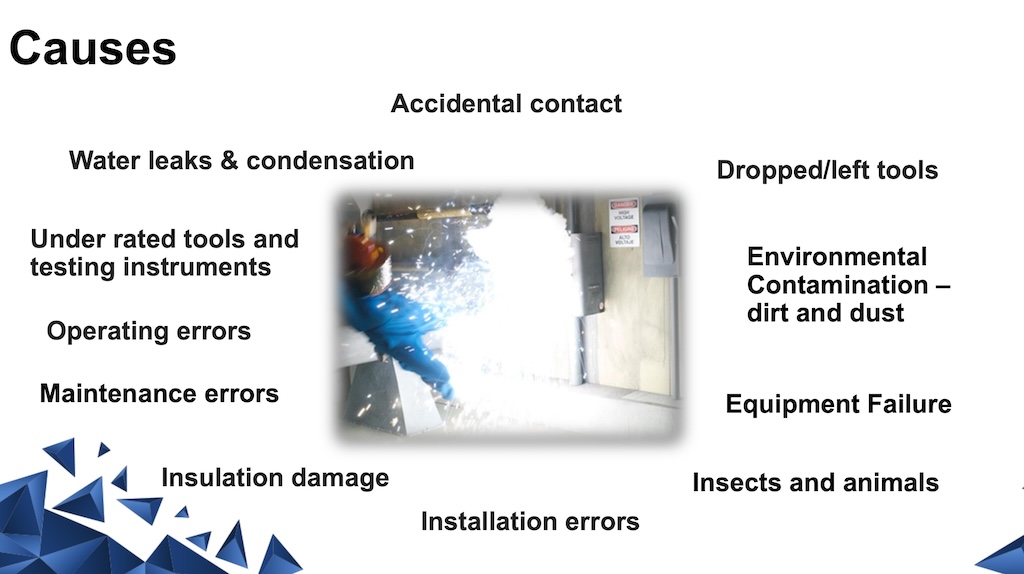

Consider this sample scenario to illustrate the point. In a manufacturing plant, a large electric motor powering the assembly line overheats due to years of neglected maintenance, with dust-clogged insulation degrading unnoticed. Without NFPA 70B’s proactive maintenance program, no inspections catch the fault, leaving the motor prone to an arc flash.

When it fails, two technicians are sent to repair it during a tight production window. Lacking OSHA 29 CFR 1910.147’s lockout/tagout (LOTO) procedures, they flip the main switch but miss a hidden secondary power feed from an emergency backup circuit, assuming the motor is de-energized. One technician probes the wiring, and the live feed triggers a violent arc flash, blasting the worker. The technician suffers third-degree burns, the second narrowly escapes and the motor shorts out completely, halting production for weeks. The plant faces hefty OSHA fines, medical costs and lost output – all consequences of failing to integrate NFPA 70B with OSHA LOTO, exposing a deadly gap in safety protocols.

Integrating NFPA 70B with OSHA 29 CFR 1910.147

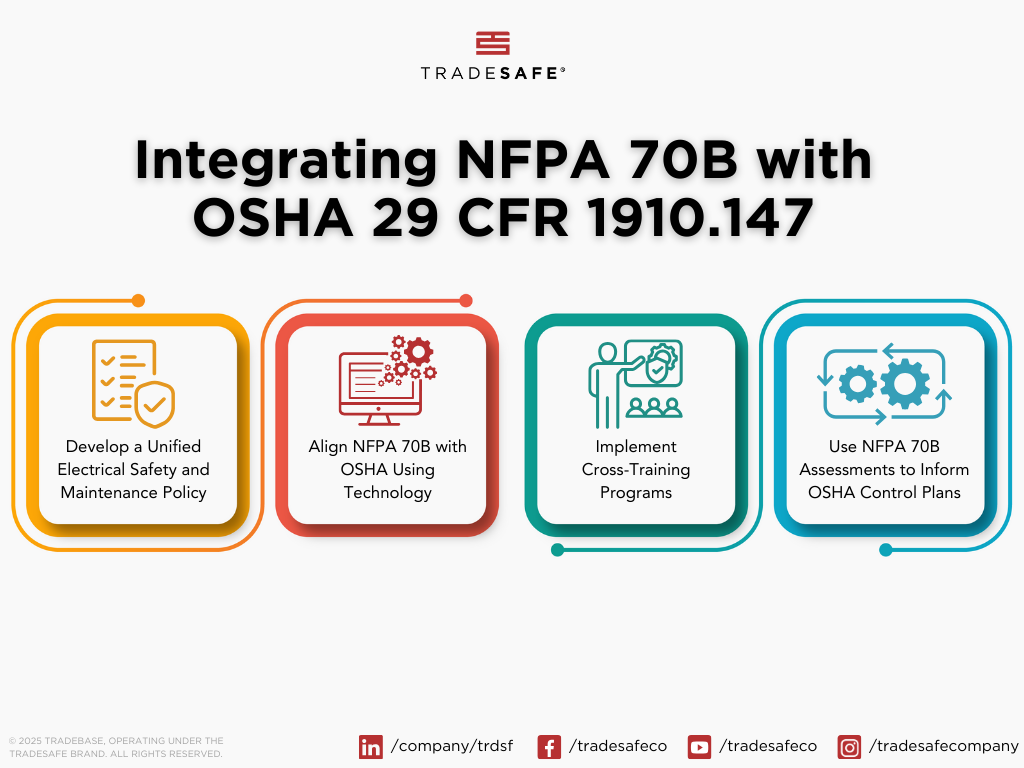

But how can organizations integrate NFPA 70B with OSHA 29 CFR 1910.147 requirements? Here are four ways to achieve this effectively.

1. Develop a unified workplace electrical safety and maintenance policy

Creating a single, comprehensive policy document that merges NFPA 70B’s electrical maintenance program requirements with OSHA LOTO standards is the foundation of this strategy. The unified policy explicitly references both standards, outlining maintenance tasks such as inspections per NFPA 70B and LOTO procedures such as energy isolation and try out procedures per OSHA to ensure they’re addressed together.

For example, at a bottling plant, management, maintenance and the safety department strategize together and draft a 10-page policy titled “Electrical Safety and Maintenance Protocol.” It mandates NFPA 70B quarterly motor inspections and requires OSHA LOTO for any repair. When a conveyor motor jams, technicians should first lock out both its main and backup power feeds and tag them, try the start/stop switches and inspect the motor’s wiring for wear, ensuring both steps are followed before work begins. Conducting frequent, documented reviews and audits of the program ensures effectiveness.

2. Use technology to align NFPA 70B with OSHA standards

Coordinating NFPA 70B’s maintenance intervals with OSHA’s 29 CFR 1910.147(d) LOTO execution can use asset management software like a computerized maintenance management system to synchronize these tasks seamlessly. The system schedules maintenance, like switchgear inspections every 12 months and triggers corresponding LOTO steps, such as locking out three energy sources, while tracking compliance in real time.

To implement this, organizations can input NFPA 70B schedules and OSHA LOTO procedures into the software, set alerts for upcoming tasks and generate reports showing the completion of both. This integration strategy ensures maintenance and LOTO happen in sync, preventing energized work during repairs. It also reduces manual errors like missed LOTO steps with automated tracking and using software offers real-time compliance visibility to simplify audits and prove adherence to both standards.

3. Implement cross-training programs

Training maintenance and safety staff together on NFPA 70B’s testing protocols and OSHA LOTO requirements blends skills like equipment maintenance and energy isolation into a unified skillset. Hands-on sessions ensure workers grasp how these standards interrelate and apply them together.

Implementing this strategy involves partnering with trainers, such as NFPA or the OSHA Training Institute, for annual workshops featuring practical drills, like de-energizing a panel while assessing its condition, followed by competency tests in both areas.

4. Use NFPA 70B assessments to inform OSHA control plans

Using NFPA 70B’s condition assessments from Chapter 6 to update OSHA 29 CFR 1910.147(c)(4)(i)’s energy control plans ensures that LOTO procedures reflect the equipment’s current state. Maintenance findings, like degraded components or new energy sources, directly refine these plans for accuracy. To implement, organizations can conduct NFPA 70B assessments such as thermography or visual checks per schedule, then revise OSHA LOTO plans accordingly, like adding a lockout step if a hidden power feed is found and review updates with teams during safety briefings.

This strategy keeps LOTO procedures precise and current, preventing surprises like unlisted energy sources. It also links equipment health directly to worker safety and strengthens compliance by grounding OSHA plans in NFPA 70B’s real-time data.

Training employees to comply with codes and standards

Equipping workers with the integration strategies discussed above requires training that seamlessly combines electrical maintenance practices with hazardous energy control procedures. These three training components will help organizations implement the best training methodologies for workers to learn them.

1. Understanding NFPA 70B maintenance best practices

This component teaches workers the fundamentals of electrical equipment maintenance to prevent failures that could lead to hazards like fires or shocks. It covers NFPA 70B’s core practices: inspection, testing and repair. Trainees learn why regular maintenance matters, such as using thermographic scans to spot overheating breakers or testing insulation to catch degradation early, ensuring equipment remains reliable and safe for operation or repair.

The goal is to instill a proactive mindset so that workers maintain systems systematically rather than react to breakdowns.

Training method: Hands-on demonstrations: Setting up stations with real equipment offers the most effective way to teach NFPA 70B maintenance. Guided by instructors, trainees can perform tasks such as torquing connections, testing a relay’s functionality or conducting work with electrical personal protective equipment, simulating real-world maintenance.

2. Mastering OSHA’s 29 CFR 1910.147 LOTO procedures

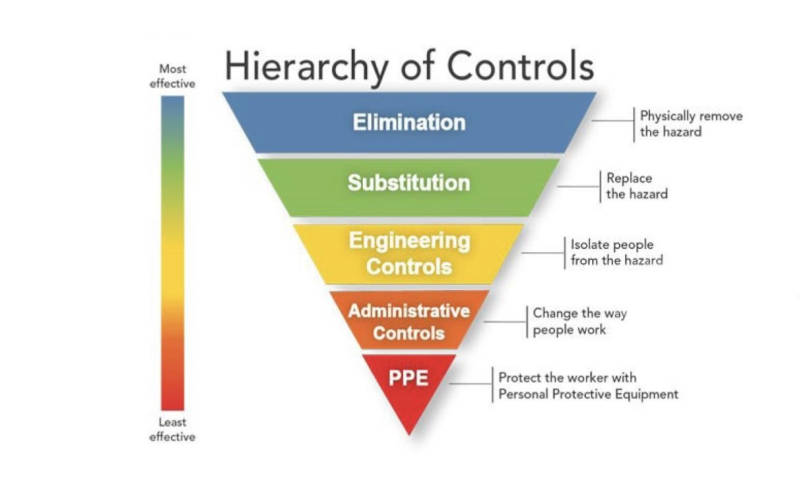

This component focuses on training workers to execute LOTO procedures with precision, ensuring they can identify and isolate hazardous energy sources, apply locks and tags and verify a zero-energy state before maintenance begins. Based on OSHA 29 CFR 1910.147(d), it should teach the step-by-step process: shutting off power, securing energy points, releasing stored energy and confirming de-energization. Mastery here is critical because missing a step can expose workers to live circuits.

The aim is to make LOTO second nature, protecting workers during every maintenance task.

Training method: Step-by-step procedure simulations: Using a mock control panel with multiple energy feeds — such as alternating current power and a battery backup — provides the strongest training for OSHA’s LOTO process. Instructors can guide trainees through the LOTO steps. For instance, trainees might isolate a simulated conveyor motor, locking out two feeds and testing for voltage, repeating the drill until they perform it flawlessly. This repetition in a controlled setting builds proficiency and confidence, making sure that workers can handle complex energy systems safely.

3. Applying integrated worker safety scenarios

This component ties NFPA 70B maintenance and OSHA 29 CFR 1910.147 LOTO together, training workers to assess equipment condition and de-energize it safely in realistic, combined contexts. It emphasizes the standards’ synergy, which is that maintenance reveals faults that inform energy control, while LOTO enables safe repairs based on equipment state.

Trainees practice holistic scenarios, such as inspecting a motor for wear and then locking it out before fixing it, learning to see these tasks as interconnected rather than separate. This prepares them to address both equipment health and worker safety in one fluid process.

Training method: Simulated maintenance and LOTO drills: Setting up a scenario like an overheating pump motor offers the most effective way to train integrated compliance. Trainees begin with an NFPA 70B inspection, then execute OSHA LOTO by locking out the main and backup feeds, tagging them and verifying de-energization before repairing the issue.

For example, a technician might spot degraded insulation during a drill inspection, adjust the LOTO plan to isolate an overlooked circuit and complete the task using both standards seamlessly. This hands-on simulation mirrors workplace realities, reinforcing how maintenance and energy control interlock to prevent hazards.

Common NFPA and OSHA implementation challenges and solutions

When it comes to training, there are some challenges when it comes to implementing both NFPA and OSHA standards. Here are some ways to resolve those challenges that will allow workers to incorporate both organizations’ standards.

1. Conflicting priorities

Maintenance teams often struggle to balance keeping equipment running while also doing necessary repairs and compliance checks. Production departments may push to minimize downtime, which can lead to deferred maintenance and increased risks of equipment failure.

Solution: Schedule maintenance during planned outages to meet both standards. Prioritize certain jobs and define the critical path.

One effective way to address this issue is by aligning maintenance schedules with planned production downtimes. This ensures that essential maintenance work gets done without disrupting operations. Preventive maintenance planning, predictive analytics and coordination between departments can help optimize scheduling, reducing conflicts and improving equipment reliability.

2. Lack of worker awareness or training on dual standards

Maintenance personnel often need to comply with multiple regulatory standards, such as NFPA and OSHA. Without proper training, workers may misunderstand overlapping rules, leading to non-compliance, safety risks or inefficiencies.

Solution: Conduct cross-training sessions to clarify overlapping rules.

A structured training program that covers both NFPA and OSHA standards helps workers understand their responsibilities. Cross-training ensures that employees are aware of best practices, reducing the risk of violations. These sessions can include hands-on training, case studies and regular refresher courses to keep everyone updated on changing regulations.

3. Inconsistent documentation across NFPA and OSHA requirements

Many organizations struggle with maintaining consistent documentation, especially when complying with multiple standards. Variations in reporting formats, missing records or outdated logs can lead to compliance issues during audits or inspections.

Solution: Use integrated software to track compliance tasks and follow through with responsible persons and completion dates, storing evidence or documents to ensure closure.

Implementing a centralized compliance tracking system ensures all maintenance records are accurately logged and updated. Integrated software can automate documentation, generate reports and send alerts for upcoming inspections.

By addressing these challenges with the right solutions, maintenance teams can work more effectively, ensure compliance and contribute to a safer, more productive work environment.

Moving beyond NFPA 70B compliance

As workplace safety becomes an increasingly complex landscape, the integration of NFPA 70B and OSHA 29 CFR 1910.147 represents more than regulatory compliance, it shows commitment to preserving human life. When safety standards remain kept rather than integrated, what unseen vulnerabilities might we be creating in our workplaces? Perhaps the most crucial conversation isn’t about compliance at all, but about how we build systems where protection becomes instinctive rather than procedural to protect workers’ well-being.