Real-time energy and compressed air monitoring gives manufacturers visibility and control to drive environmental initiatives.

Learning objectives

- Explore how to achieve plant sustainability goals through energy monitoring.

- Understand how real-time energy and compressed air monitoring gives manufacturers the visibility and control to drive environmental initiatives.

- Assess the different solutions available to track energy consumption and efficiency.

Energy insights

- Manufacturers are increasingly using technology to monitor compressed air and electricity in real time, helping them reduce waste and improve energy efficiency as part of broader sustainability strategies.

- By optimizing how facilities consume energy, companies can cut costs, lower carbon emissions and gain a competitive advantage while meeting sustainability goals.

Meeting corporate sustainability initiatives is a high priority around the world. According to a 2024 sustainability report, 85% of global executives say their companies have increased sustainability investments in the past year. Half of the companies included in the report have already begun to implement technology solutions as part of their strategies to reach environmental goals, while another 42% are planning to do this within the next two years.

In addition to their own scope one emissions, these companies are also focused on minimizing scope two and scope three emissions throughout their supply chains. Nearly half (47%) of companies require suppliers and business partners to meet specific sustainability criteria. Having successful sustainability initiatives can give original equipment manufacturers and suppliers a competitive advantage.

To reach sustainability goals, it is critical that manufacturers have visibility into how their operations use energy as well as the ability to control this usage. This includes the electricity that equipment uses and the energy used to generate other resources, such as compressed air.

Real-time compressed air and energy monitoring makes it possible for manufacturers to gain a greater understanding of how assets, lines and plants use energy. With this knowledge, their teams can better address waste and optimize use. By achieving this level of control, companies can more effectively and accurately track and reach sustainability goals.

Realizing energy savings opportunities

Pneumatic systems can be found in almost every industry, but they are especially prevalent in factory automation, automotive, food and beverage, life sciences, semiconductor and utilities applications. On average, 20% to 30% of a facility’s total energy consumption goes toward generating compressed air. But once it is generated, most manufacturers have no idea how it’s used or how much of it goes to waste. This lack of visibility makes it challenging to optimize and control use, which in turn makes it challenging to meet sustainability goals.

It may surprise most manufacturers to know that, between leakage and machine suboptimization, around 30% or more of the compressed air a plant generates goes to waste. Machines often consume compressed air even when idle. This inefficient use of air is called standby loss.

Leakage is another significant form of waste. Leaks can develop in pneumatic systems over time and compressed air can escape. With leaks, energy waste is not the only expense. On average, 76% of businesses still manually test for compressed air leaks across their facility. Manually checking for leaks can cost an average of $46,000 per machine due to service equipment and training investments and leaks can go undetected and grow between the periodic checks.

At the same time, manufacturers also have a great opportunity to address standby power, the power consumed by idle equipment. Machine tools are energy intensive, making up about 53% of electricity consumption by end use. Although they run only 15% to 40% of the time, they still consume high power when idle. Optimizing machine usage can cut energy use by 10% to 25%.

Additionally, identifying and reducing peak loads can directly reduce the net capacity surcharge. Reducing the baseload by optimizing the highest consumers can significantly reduce overall energy consumption.

Manufacturers that can identify and address compressed air waste and standby power have significant opportunities to improve energy efficiency, optimize energy use, reduce related carbon emissions and meet net zero goals. Real-time compressed air and energy monitoring makes it possible.

Assessing ways to track energy consumption, efficiency

With so many companies either implementing or planning to implement technology solutions as part of their sustainability strategies, it’s important to understand which solutions are available and what their limitations are.

Some utility monitoring solutions are developed in-house based on programmable logic control or supervisory control and data acquisition platforms. While they can be customized, these do it yourself solutions often require programming and may have limited data analytics and visualizations. They may also be difficult to integrate with existing industrial internet of things technology.

Cloud-based applications are another option, typically integrated with enterprise systems through software-as-a-service models. However, they can be expensive to implement, which makes it difficult for companies to start small, prove success and scale up. It may also be difficult to justify the recurring cost of software as a business grows.

Energy consulting firms can provide manufacturers with audits and advice, but they may lack the expertise to implement projects that address findings. This leaves manufacturers on their own to find the right technology for their needs.

Utility metering vendors offer energy monitoring devices with proprietary software applications, which can lock vendors into specific hardware and prevent integration of third-party devices.

Overall, these products, services and audits lack the comprehensive visibility needed to track energy use, the automation and control to optimize consumption and the scalability to prove success and invest over time. What’s more, personnel may experience data overload and lack the expertise to maximize the value of these solutions. The sheer volume of data from machines can be difficult to analyze and is often siloed.

In comparison, there is now a scalable, plug-and-play integrated solution that monitors compressed air and energy use in a comprehensive way in real time. Its software applications have an intuitive interface and dashboards that effectively provide visual insights and alerts that are easy to understand without specific technical expertise.

Optimizing compressed air and electricity use

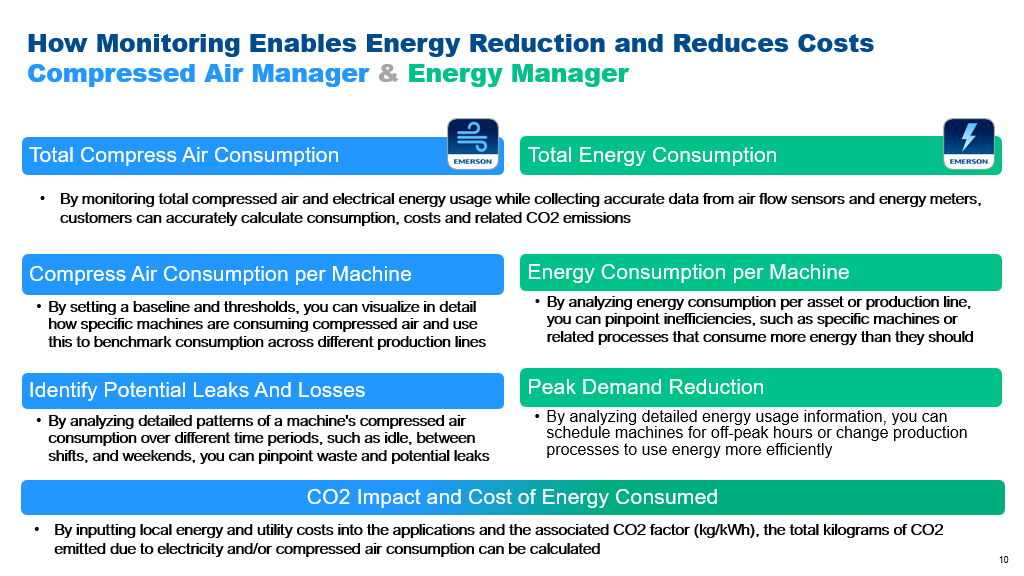

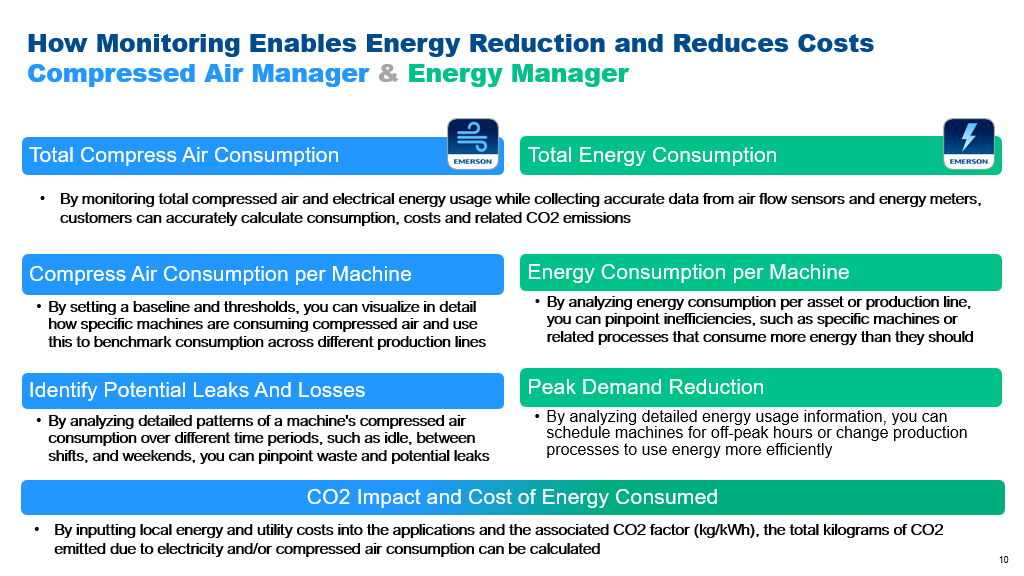

By tracking both compressed air and electricity use at the same time, manufacturers can gain a greater understanding of how their facilities consume energy and increase the number of ways they can identify and address inefficiencies. And by using a solution that is easy to install, use and scale, companies can get started quickly and maximize the value of their investment.

The preprogrammed and pre-engineered cabinet solution includes smart airflow sensors and two applications, one for compressed air monitoring and the other for energy monitoring, on the same edge hardware.

Both software applications provide advanced analytics from an individual machine level up to a complete line or facility. Energy dashboards show asset-specific energy consumption, power demand, voltage- and frequency-related charts, associated energy costs and carbon dioxide (CO2) emissions. Compressed air dashboards identify leaks and display key performance indicators and metrics such as air flow, pressure, energy costs and CO2 emissions.

Easy access to these key performance indicators and metrics gives sustainability teams a unified view to track and drive initiatives. And using these dashboards, operators can uncover opportunities for improving energy efficiency, such as machines that waste energy while idle or early-stage leaks. The dashboards can also reveal when simultaneous operations during peak hours lead to spikes in energy consumption, allowing operators to strategically adjust shifts and enhance overall energy management.

For instance, one facility used the solution and identified several inactive systems running during the third shift shutdown. This allowed the site to reduce consumption during third shift production. In the first six months, the initiative resulted in about $125,000 in savings.

When a plant improves energy efficiency, operational efficiency naturally follows. As companies realize energy benefits and cost savings, they also see productivity benefits and cost savings. For example, it can improve overall equipment effectiveness values and lower per-unit production costs, too.

The scalability of the solution makes it possible for manufacturers to begin with one machine, production line or asset — like a proof of concept — and then expand from that point. This approach allows them to maximize their initial investment while building valuable expertise along the way. Manufacturers can scale up when they are ready, adding more sensors. As they scale, the value and return on investment (ROI) increases as well.

Manufactures who are currently using the compressed air monitoring solution are seeing a 30% to 50% reduction in compressed air consumption and typically realizing ROI in less than two years.

Making good energy strategy good business strategy

To better meet sustainability goals, it’s important that the monitoring technology a company uses is easy to access and use. And, to meet other business goals, it’s important that solutions are quick and easy to install and provide fast ROI.

Whether companies are taking the first step of their sustainability journey or starting the next leg, partnering with a digital transformation expert with a comprehensive portfolio makes it possible to go farther.

An expert partner can help manufacturers maximize the value of their sustainability investments. They can identify and prioritize opportunities by examining the largest energy-consuming assets and pinpointing areas of high utility usage where immediate efficiency improvements can be made for cost savings. They can also provide a future-proof platform that is scalable and adapts with evolving needs and lower total cost of ownership.

Real-time compressed air and energy monitoring makes it possible for manufacturers to get a clear picture of waste and take action to optimize energy use. In this way, addressing compressed air and energy consumption at the same time offers a significant opportunity for manufacturers to meet sustainability goals — and gain a competitive advantage.