An effective asset management plan improves maintenance practices, reduces costs and makes the journey much easier for maintenance and manufacturing professionals.

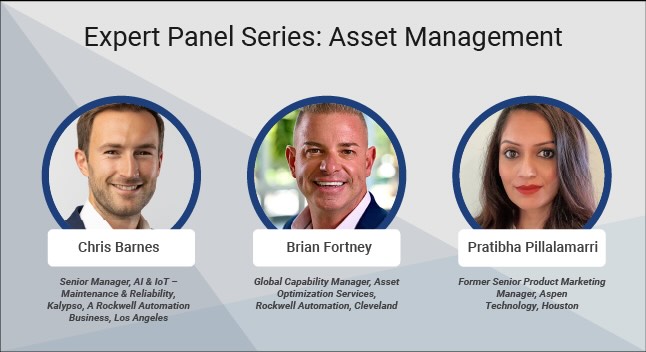

Respondents

- Chris Barnes, senior manager, AI & IoT – maintenance & reliability, Kalypso, a Rockwell Automation business, Los Angeles

- Brian Fortney, global capability manager, asset optimization services, Rockwell Automation, Cleveland

- Pratibha Pillalamarri, former senior product marketing manager, Aspen Technology, Houston

Question:

How does effective asset management contribute to improved maintenance practices?

Brian Fortney: An effective asset management strategy will set the rules of the road for maintenance programs. You can be the hero of your epic journey, but you will need allies and you will face obstacles. Maintenance partners can be great allies in the journey, but you may have to train them to enable support of your strategy. The obstacles to be vanquished include poor documentation, outdated systems, mismanagement of storerooms, required training, and inconsistent repair quality. Communicating strategy and outcomes is key to enabling improved maintenance practices to support effective asset management.

Pratibha Pillalamarri: Effective asset management improves maintenance practices by enabling proactive strategies and optimal resource allocation. Through predictive maintenance techniques, organizations can prevent equipment failures, minimizing downtime and optimizing asset reliability. Comprehensive asset management solutions complement existing condition-based maintenance, allowing maintenance activities to be triggered based on asset condition rather than fixed schedules. Not just that, leading solutions provide users with actionable insights allowing for intervention.

They also notify users of an optimal window by considering the financial impact of various scenarios. By integrating with enterprise asset management (EAM) and computerized maintenance management systems (CMMS), these asset management solutions can request work orders, allowing for timely interventions. Maintenance personnel can also document their learnings or effectively utilize inbuilt FMEA libraries. By analyzing performance data, equipment and process, organizations can optimize asset performance and utilization, reducing energy consumption and maximizing efficiency. By implementing proactive strategies, organizations can optimize resource allocation, ensure regulatory compliance, and ultimately enhance asset reliability and performance.

Question: In your experience, what are the key challenges organizations face when trying to align asset management with maintenance goals?

Brian Fortney: Time and money are the mortal enemies of the hero on the Asset Management journey. Your time is consumed most days by the urgent, with the important sometimes slipping to the background. Money is key to driving the strategic transformation you may visualize. Data is your strongest weapon in gaining more allies to support this journey. Using the data to support strategic requests will likely increase support. Be clear on your priorities, what are the must do’s, should do’s and could do’s.

To combat the time challenge, ensure that the right functions are owning the reactive issues that come up and dive for better preventative maintenance efforts to reduce the unplanned issues that push most leaders into a constant reactive state.

Budget also plays a big factor, as well. In many companies, projects are done as capital expenditures and often funded by a corporate entity with little or no provision for the ongoing support and maintenance. The budget for the maintenance then falls on the local plant, who has little to no additional funding to ramp up a new program. These are things that need to be discussed and planned for early to ensure success.

Question: What metrics or key performance indicators (KPIs) are most relevant for assessing the success of asset management in maintenance?

Brian Fortney: As you continue your journey, mark your progress. Your KPIs are the benchmarks that you can use to achieve two things: the first is to mark change based on the implementation of your strategy, and the second is to gain further support/funding to achieve your goals.

The metrics you choose need to be aligned to what the organization and leadership are trying to drive. The closer the alignment, the greater the opportunity that the data will be reviewed seriously and leadership will continue to provide support for or accelerate your asset management initiative. Conversely, if you have misaligned KPIs that leadership overlooks or doesn’t see as important, you will be tuned out and a lack of support will weaken any success.

Question: Are there any common misconceptions about the relationship between asset management and maintenance that you often encounter, and how to you help resolve them?

Brian Fortney: Continuing the storyline of the hero, with an epic journey to an optimized asset state, the most common misconception between Asset Management and Maintenance is that they are on separate journeys. They are not. They are two heroes on a journey to the same desired state; they just have different powers. Not every superhero has the same power, right? Involving the maintenance organization in the strategy that developed and implemented is key to resolving this. This is true for every step in the process, from identifying current state, to mapping the journey, to establishing the milestones of success. As this alignment is enabled, your chances of success increase as you have allies that are close to the assets and can provide invaluable support and insight. They will also be key players in the execution of your efforts.

Pratibha Pillalamarri: One common misconception is that asset management and maintenance are interchangeable. While maintenance is a subset of asset management focused on ensuring asset reliability and performance, asset management has a broader scope encompassing the entire asset lifecycle, from planning to optimization.

Another misconception is that heavy investment in maintenance alone guarantees optimal asset performance. Effective asset management requires a holistic approach that integrates maintenance with operations and performance monitoring, aligning with broader organizational goals.

To address these misconceptions, it’s crucial to emphasize the interconnectedness of processes and asset performance. Demonstrating how a comprehensive asset management strategy contributes to improved asset performance, cost reduction, and sustainability can clarify their interrelationship and promote a more integrated approach to managing assets.

Question: How can organizations ensure proper documentation and information management within the asset management framework to support maintenance activities?

Brian Fortney: As our hero navigates the path to true asset optimization, the darkest cave they likely will need to explore is maintenance documentation. The metaphor of darkness is apt, as that is what many leaders are left in, the dark. Driving a true asset management strategy involves the systems and processes to support your efforts, documentation is a must have to achieve your goals. Leveraging a CMMS is a key step in driving the behavior.

Establishing a reality that no job is complete until documentation is logged, along with rewarding and shining a light on the team members who consistently supply the best information are steps that can help you move out of the dark cave and into the light quickly.

Question: How does asset life cycle management impact the overall maintenance strategy, and what best practices should be considered?

Brian Fortney: On the journey, lifecycle management is an area where the road can twist and turn, and if our hero is not careful, they can find themselves heading off in the wrong direction. When it comes to best practices, the first step is to set a north star, maybe it’s mitigating cyber risk, maybe it’s opportunistic modernization, possibly it’s maintain operations and accept and mitigate lifecycle risk.

Once you establish, gain agreement and budget, you can map your path to your desired state. Regardless of what your north star is, you will need to plan for the near term. We know that customers are well aware of the risk of supply chain to their production, so maintaining ready access to critical spares and being able to quickly replenish spares through purchase or repair is a critical balancing act that can’t be ignored. As our hero identifies their north star, they will find assurance they’re heading in the right direction.

Question: In your opinion, what are the emerging trends in asset management that are likely to reshape maintenance practices in the near future?

Brian Fortney: The road is always shifting in the journey. Our hero needs to be willing to adapt quickly, some of the major trends will be the influence of AI upon decision-making for asset management and maintenance and the impact on modernization that efforts around cybersecurity will drive. As more government regulation regarding cybersecurity comes into play for critical industries the requirement to modernize to a secure infrastructure will change the game for many manufacturers impacting their existing strategies.