Asset management is a critical aspect for manufacturers and it can help improve a facility’s automation practices with strong data.

Respondents

- Chris Barnes, senior manager, AI & IoT – maintenance & reliability, Kalypso, a Rockwell Automation business, Los Angeles

- Brian Fortney, global capability manager, asset optimization services, Rockwell Automation, Cleveland

- Pratibha Pillalamarri, former senior product marketing manager, Aspen Technology, Houston

Question:

How do you prioritize assets for automation, and what criteria should be considered in this process?

Brian Fortney: Thinking of criticality as a function of availability and lifecycle measured against impact on production provides a high-level matrix on what decisions to make regarding inventory, repair vendors, training, and sustainability/modernization planning. As prioritization is established, it will drive the spend and support structures required to enable your strategic journey. Have a lead on planning for modernization investment should also be the goals, as when funding becomes available, you will want to move fast to take advantage of opportunities.

Question: What strategies can organizations employ to ensure scalability and adaptability of asset management systems in evolving automated environments?

Brian Fortney: This is an opportunity to pull together engineering, IT and plant management to talk candidly regarding the current state of your systems and whether they can scale to meet the needs of tomorrow. Most understand that the expectations of production will not remain static, nor can we assume an uninterrupted supply chain. We must challenge our systems and cross-functional teams to come together to drive this scale. This is also an opportunity to look for great ideas throughout your organization. It’s never a bad idea to identify other heroes that may be further on the journey and see what advice they may have within your organization.

Pratibha Pillalamarri: To ensure scalability and adaptability of asset management systems, organizations should first identify assets crucial to plant operations or those that significantly impact the environment and bottom line.

Selecting an asset management solution that is easy to deploy and user-friendly is crucial. The solution should empower subject matter experts by providing mitigation strategies readily accessible for quick decision-making.

After deploying the solution on a select group of assets and tracking the results, it’s essential to ensure the system has a scalable architecture. Leading solutions offer the capability to transfer trained models to similar assets or services, streamlining scalability.

Additionally, maintaining visibility across assets, processes, and business health is vital. With quantifiable results and clear insights, users can more easily adopt the solution, understanding its impact on operations and overall performance. This comprehensive approach fosters a culture of continuous improvement and adaptability in managing assets.

Question: How does real-time asset monitoring contribute to proactive decision-making in an automated environment?

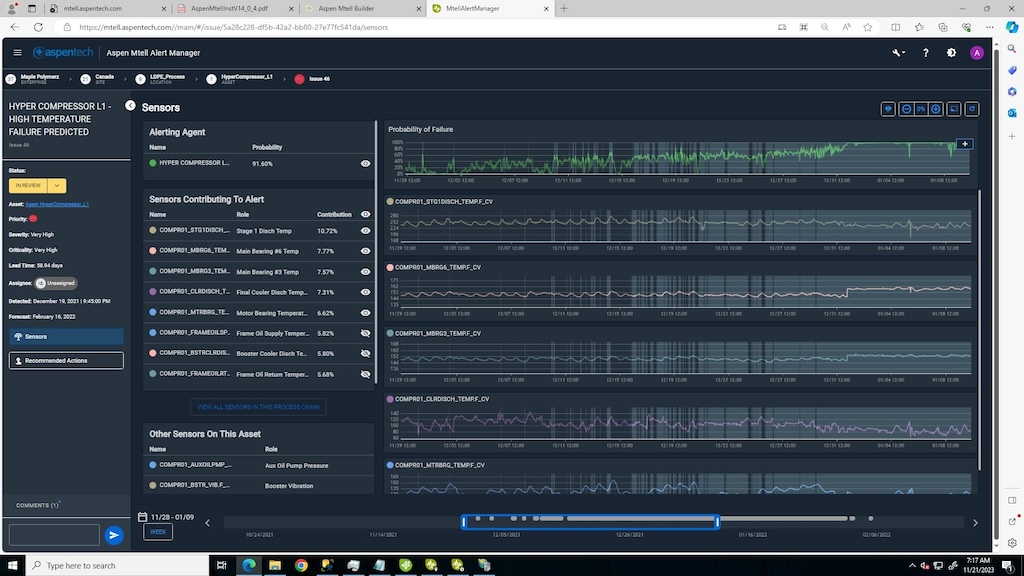

Pratibha Pillalamarri: Real-time asset monitoring plays a pivotal role in proactive decision-making by providing visibility into asset performance, health and status.

First, real-time monitoring enables organizations to detect anomalies or deviations from normal operating conditions instantly. This early detection allows for timely interventions, minimizing potential disruptions and preventing costly downtime.

Secondly, by continuously collecting and analyzing data from assets in real-time, organizations can identify trends, patterns, and potential issues before they escalate. This proactive approach allows for planned intervention: operating regimes can be adjusted before degradation sets in, or maintenance activities can be scheduled based on actual asset condition rather than fixed schedules, thereby optimizing asset reliability and lifespan.

Real-time monitoring also facilitates informed decision-making by providing actionable insights and performance metrics. Stakeholders can access up-to-date information, allowing them to make data-driven decisions that align with organizational goals and priorities.

In summary, organizations can anticipate, identify and address issues promptly for improved operational efficiency.