Digital medium voltage (MV) switchgear adoption is growing in the U.S. and offers many potential benefits for manufacturers. See tips on how digital MV switchgear changes how power is being adopted and potential benefits and barriers.

Learning Objectives

- Explore how digital switchgear optimizes power management through real-time monitoring, precise control, and advanced fault management in industries.

- Learn about the present and future demand for MV switchgear in the US, influenced by economic expansion, legislative changes, and increased investment in research and development.

- Explore factors facilitating the adoption of digital MV switchgear and identify potential obstacles facing the implementation of this advanced technology.

Medium voltage (MV) switchgear insights

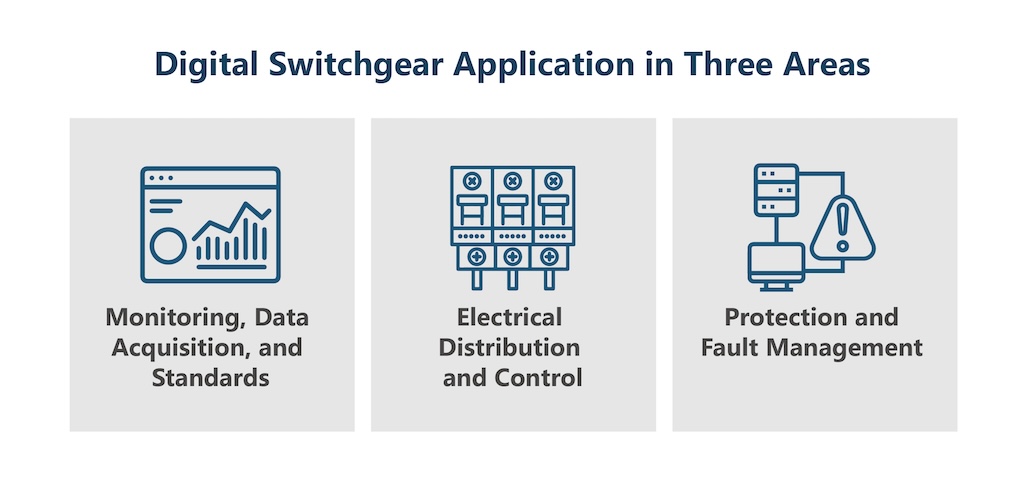

- Digital switchgear revolutionizes how power is managed and distributed in three key areas: electrical distribution and control, protection and fault management, monitoring, data acquisition, and standards.

- As the industry focuses on advanced solutions, digital MV switchgear is gaining prominence, replacing conventional ones.

- The drivers for adopting digital MV switchgear include industry demand and predictive maintenance, while the barriers include budget constraints, training, and cybersecurity concerns.

Digital medium voltage (MV = 1 to 42kV) switchgear is poised to serve as the backbone of electrical distribution systems in industrial settings. It has numerous capabilities that play a pivotal role in ensuring the efficient, reliable, and sustainable supply of electricity to various processes and equipment. The U.S. currently accounts for 5% of the global annual demand for digital MV switchgear. However, this market share will grow as original equipment manufacturers (OEMs) and industries adopt digital MV switchgear and transition to this advanced technology.

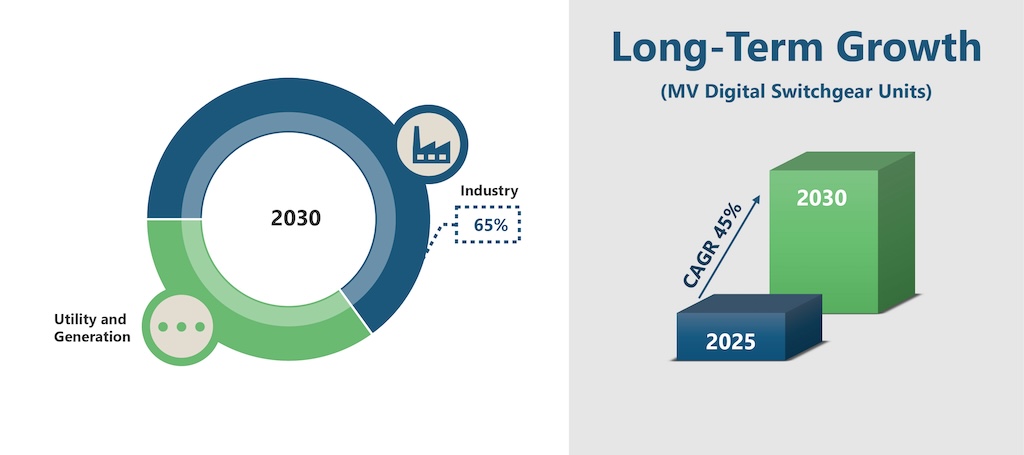

In the United States, the demand from the industry will account for 65% of the total digital MV switchgear demand — including generation, industry and utility — by 2030. This growth is driven by a technological shift from conventional to digital switchgear as the industry embraces advanced solutions because of their efficiency and reliability.

Three ways digital switchgear changes how power is managed

Industrial operations require a robust and efficient power infrastructure. Digital switchgear revolutionizes how power is managed and distributed in three key areas:

-

Monitoring, data acquisition and standards

-

Electrical distribution and control

-

Protection and fault management.

1. Real-time monitoring, data acquisition, and standards

Digital switchgear collects real-time data on power consumption and system performance through sensors and monitoring devices. This data offers valuable insights for optimizing energy usage and enabling predictive maintenance. Its seamless integration with control systems, including standards like IEC 61850, streamlines energy management efforts. Incorporating digital switchgear facilitates energy-efficient practices and supports eco-friendly initiatives by providing accurate power consumption data to meet the demand with adequate supply.

2. Electrical distribution and control

Digital switchgear ensures efficient electrical power distribution throughout industrial facilities by intermediating between high-voltage supply and low-voltage equipment. It offers intelligent load management by balancing and prioritizing power distribution based on real-time demand, enhancing energy efficiency. Digital switchgear can control power distribution precisely by enabling seamless power on/off depending on the requirement. It allows for remote operation, which enhances safety and responsiveness to changing operational needs.

3. Protection and fault management

Digital switchgear incorporates advanced protection features that detect and isolate faults and overloads, preventing damage and downtime. Equipped with sensors and algorithms, it excels in diagnosing various fault types, such as short circuits and ground faults and mitigates them.

Three catalysts for MV switchgear demand

The growth of various sectors in the industry operations is propelling the demand for reliable power management solutions, including MV switchgear, in the United States. The key drivers behind the increase in industrial activity include economic expansion, legislative initiatives and business investments.

1. Economic expansion

The rise in the US economic output in recent years is fueling significant growth in industrial activities. The U.S. Bureau of Labor Statistics (BLS) estimates robust economic growth, averaging 2.3% annually from 2020 to 2030. This economic expansion serves as a foundational driver for increased industrial activity.

2. Legislative initiatives

Since late 2021, several legislative acts have been passed to bolster U.S. economic competitiveness, innovation and industrial productivity. These include the Bipartisan Infrastructure Law (BIL), the CHIPS & Science Act and the Inflation Reduction Act (IRA). These initiatives are expected to inject $2 trillion in new federal spending over the next decade (between 2022 and 2032), spurring industrial development.

3. Increased business investment

Apart from federal spending, U.S. businesses are investing vast amounts of money, particularly in research and development (R&D). The surge in private investments resulted from implementing legislative acts such as the Inflation Reduction Act (IRA), the Bipartisan Infrastructure Law and the CHIPS and Science Act, leading to increased industrial activity.

The development in multiple industrial sectors is predicted to lead to the growth in demand for MV switchgear. It’s estimated the industry’s annual demand in the U.S. for MV switchgear will reach almost $815 million by 2030, which is an increase of almost 60% compared to 2023.

As the industry’s focus shifts to advanced solutions, digital MV switchgear is gaining prominence. PTR expects the demand for digital MV switchgear will increase significantly compared to MV switchgear’s total demand.

Ascent of digital MV switchgear due to growing demand

With a surge in demand for switchgear solutions driven by expanding industries in the U.S., digital MV switchgear for the industry will account for a 65% unit sales share of the annual digital switchgear market by 2030 and a compound annual growth rate (CAGR) of 45% for the digital MV switchgear in terms of unit sales between 2025 and 2030.

This rapid growth will result from the industry’s dedication to embracing digital solutions as the primary means of ensuring reliable, efficient and sustainable power management.

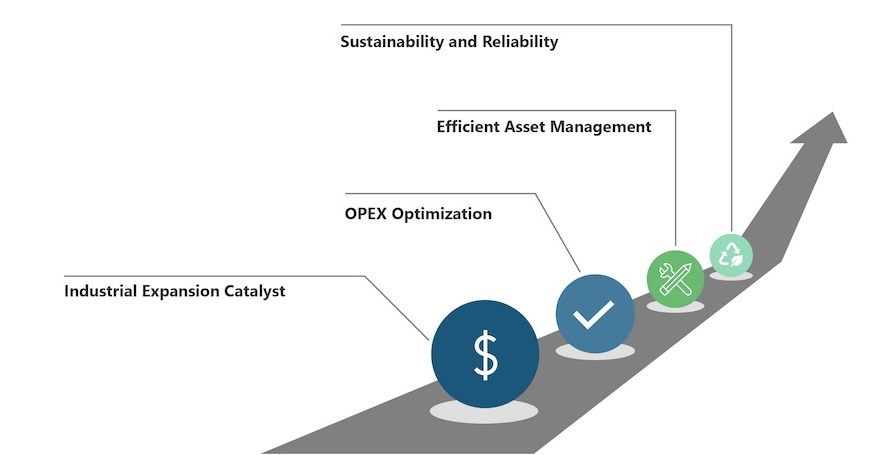

Four growth drivers and two potential barriers for MV switchgear solutions

Several key factors act as drivers, while certain factors act as barriers to the widespread adoption of digital MV switchgear solutions. As industries transition to digital solutions, embracing the benefits of digital switchgear and addressing the challenges associated with its adoption is important.

The growth drivers for adopting digital MV switchgear include industry demand, predictive maintenance, operational and maintenance cost reduction and enhanced communication capabilities.

1. Escalating industry demand

The escalating demand from industries will continue to play a pivotal role in driving the adoption of digital MV switchgear upwards. The increase in demand will lead to diverse industry sectors becoming more efficient and sustainable in power management.

2. Predictive maintenance

Predictive maintenance will be a key driver in adopting digital MV switchgear. By harnessing real-time data and advanced analytics, digital switchgear will empower industries to manage and maintain their equipment proactively, reducing downtime and improving overall reliability.

3. Operations and maintenance cost reduction

Digital switchgear will offer substantial cost-saving opportunities. Industries will significantly reduce operational and maintenance expenditures through optimized operations and streamlined maintenance, enhancing their bottom line.

4. Enhanced communication capabilities

Digital switchgear’s ability to enable bi-directional communication between the central asset management system and field equipment, bypassing traditional supervisory control and data acquisition (SCADA) systems and localized asset management systems, will revolutionize communication for predictive maintenance. This seamless integration with a workforce management system (WMS) will empower utilities to prioritize maintenance and procurement activities precisely.

As numerous factors are driving the adoption of digital MV switchgear upwards, a few barriers hinder the adoption. These barriers include budget constraints and training and cybersecurity concerns.

1. Budget constraints and training

Digital MV switchgear is challenging to adopt as there are budget constraints when implementing new technology. Industry players are reluctant to invest vast sums of money in replacing existing equipment, especially when the equipment is working fine. Large investments also are needed to train personnel to manage and operate the digital switchgear. The training process often takes months, which is not beneficial, especially when there is a rise in the industrial processes.

2. Cybersecurity concerns

The transition from conventional to digital MV switchgear raises cybersecurity concerns. The industry and the government incur substantial financial losses if the systems are hacked. Ensuring the security of digital switchgear systems and protecting critical infrastructure against cyber threats is a paramount consideration that makes industry players rethink the decision to adopt the digital MV switchgear.

The way forward for MV switchgear

As industry expansion and technological advancements continue to propel the demand for digital switchgear, the industry is geared up for a transformative shift towards a future defined by optimized energy utilization, reduced operational costs, and heightened sustainability.

In this thriving economic environment, sectors such as chemicals, automotive, data centers, oil and gas and commercial buildings are taking center stage. These industries rely on a dependable connection to their local utility grids, a need fulfilled by MV switchgear. As these sectors grow, the demand for efficient and sustainable power management solutions increases.

Leading industry players are making substantial strides in greenfield plant developments, expansions and digital initiatives. This collective commitment to digital technologies underscores a broader industry shift towards enhanced efficiency and sustainability, aligning with the capabilities of digital switchgear.

For OEMs, this presents an opportunity for growth where they will need to introduce their products with heightened awareness and cater to the customer’s evolving needs. OEMs also must invest in research and development efforts to incorporate IEC equivalent standards within the IEEE framework. Increasing marketing efforts and consumer awareness, particularly for OEMs, will be essential to drive the adoption of digital switchgear.

As industries forge ahead into a future defined by digitalization and sustainability, the role of digital MV switchgear in shaping this future will grow. Digital MV switchgear will be a cornerstone in the journey towards efficient, reliable and sustainable power management solutions.