Electrical distribution equipment is the heart of any industrial facility. Without a reliable electrical distribution system, operation of any facility would be impossible. From manufacturing processes to lighting, security and environmental controls, nothing operates without a reliable flow of electricity.

Electrical distribution equipment is the heart of any industrial facility. Without a reliable electrical distribution system, operation of any facility would be impossible. From manufacturing processes to lighting, security and environmental controls, nothing operates without a reliable flow of electricity.

Switchgear and switchboards provide distribution and protection to various types of electrical load equipment in a facility. Switchboards are more commonly used in commercial and light industrial applications, while switchgear is usually specified in heavy industrial applications where the demands on the equipment require more robust construction.

Perhaps somewhat surprisingly, the condition of this equipment (including regularly scheduled maintenance) has not been a primary concern in most facilities; indeed, many facility managers do not think much about it until a failure in the electrical distribution system occurs. This condition will inevitably lead to a process-interrupting failure, and it creates an elevated safety and property risk as well. Maintenance of electrical equipment like switchgear is critical for proper protective functioning and reliability of the distribution system.

Switchgear and switchboard components such as overcurrent protective devices, which include fuses, circuit breakers and protective relays, are fundamental to the task of protecting the system as well as reducing hazards for electrical workers. When these devices are maintained well, they operate optimally to clear any fault condition — from a simple overcurrent event to a bolted or potentially hazardous arcing fault.

While fuse technology has not changed substantially over the past two decades, power circuit breaker and protective relay technology have undergone significant design improvements since the early to mid-1980s. Older power circuit beakers were designed around an open iron frame structure with electromechanical trip units. These devices needed iron frame construction in order to have the ability to withstand the fault current conditions present in many facilities, and were designed with an open-style construction to allow the extensive maintenance that was required to keep the devices functioning properly. Often, older power circuit breaker designs required the use of limiter fuses added to the circuit breaker to protect the breaker at fault current levels higher than those for which the breaker was rated. These limiter fuses added significantly to the size of the device, and consequently to the overall size of the switchgear.

Modern power circuit breakers are designed using space-age materials in very compact formats with digital trip units. They are also designed for significantly reduced maintenance requirements. These products now offer very high fault-current withstand capabilities without the use of limiter fuses. Since power circuit breakers provide such a vital function in protecting the electrical system, as well as reducing the risk to electrical workers from arcing faults, these design improvements are a quantum leap forward in equipment and personnel protection. They have very low maintenance requirements and allow new switchgear to be much more compact than older open iron frame circuit breaker designs.

Retrofit options are now available to extend the life of existing switchgear, which could be a more cost-effective choice for some facilities.

Options available

Facility managers faced with the choice of replacing or retrofitting their existing obsolete switchgear to take advantage of the capabilities of the newer generation of circuit protection technology should make an informed choice; there are many factors to consider in this decision. One of these factors, of course, is the initial capital cost, along with potential disruption to the facility’s processes and workflow during the course of changing out the equipment.

Because newer switchgear designs are significantly smaller in size than the equipment to be replaced, this usually presents a problem regarding placement of the existing conduits. When the existing switchgear has service conductors that enter through below-grade conduits (i.e. bottom-fed), the available conduit entry area in the new replacement equipment usually will not line up properly with the existing conduit stub-ups in the slab. The same is true of the feeder circuit conduits exiting the equipment at the bottom. Because the conduits’ entry areas in each vertical section usually will not line up properly to the new switchgear, the concrete floor slab and housekeeping pad must be broken up, conduits moved and floor slab and pad re-poured. This process can be extremely expensive, often costing more in labor and material than the cost of the new switchgear. The same is true of overhead conduits and busduct connections. Rerouting the overhead line and load side conduits can be a very expensive process, which adds to the cost of replacing the equipment.

Demolition of the old equipment and replacement with new switchgear also presents a cost problem for the facility, due to the length of process downtime that is involved. Unless process loads can be rerouted temporarily during the construction, one must consider the cost of lost production and other process disruptions when making the decision. Fortunately, new design capabilities exist that will reduce the cost of upgrading the existing equipment, while still providing modernization of the equipment function.

Electrical switchgear has two types of components — passive and active — that make up the system. Switchgear passive components include steel framing channels, cover plates, barriers, horizontal and vertical bus structures and other components that make up the mechanical structure of the equipment. Unless the physical structure has been subjected to abuse or extreme environmental conditions, they will remain serviceable.

The critical active components are the circuit breakers or fused devices that comprise the overcurrent protective system. These are the crucial devices that must be upgraded to extend service life, improve reliability and reduce maintenance of the equipment.

Retrofitting is a general term that is used to define any process that allows for modernization and life extension of electrical equipment. Several different retrofit strategies exist for adapting modern circuit breakers into existing LV and MV switchgear structures. Designs are available to fit more than 95% of the electrical switchgear currently installed in the U.S. These retrofit products are designed and tested to the relevant specification requirements that apply to new switchgear such as ANSI and UL. To better understand these strategies and products, it’s helpful to offer some definitions of the various processes and designs that are available. Both direct replacement of circuit breakers and breaker retrofills fall under the general category definition of retrofits.

-

Direct replacement device — This is typically an LV or MV circuit breaker that is designed to fit directly into the existing OEM switchgear cell, without requiring any modification to the circuit breaker cell in the switchgear. The advantage of this design is that it allows a new device to be installed into the existing equipment, with very little modification to the switchgear cell. A major advantage of this procedure is that it requires a minimal (if any) outage on the equipment bus, which reduces downtime.

-

Retrofill — This option is similar to the direct replacement option (meaning the end result is the same), but the retrofill process usually requires a longer bus outage, during which the internal circuit breaker cell is modified to accept the new circuit breaker. The retrofill process is often used in lieu of the direct replacement option for larger devices such as main breakers and tie breakers. In these cases, because of the size of the replacement device, there may not be adequate room in the existing circuit breaker cell to allow for the intermediate cradle that is used in the direct replacement option.

-

It’s also important to note that in both retrofill and direct replacement options, new cubicle doors are provided to match the existing equipment and new circuit breaker face.

Taking the first step

Many innovative options are now available for modernizing and extending the life of electrical equipment, including direct replacement of breakers and breaker retrofilling. These options will improve safety; provide higher reliability; reduce maintenance requirement costs for industrial facilities and capital outlay for new equipment; and and they can be done without the disruption and additional costs of demolition of the old equipment. Guidance on the appropriateness of these options for your facility — and more importantly, implementation — is available from several manufacturers of electrical distribution equipment.

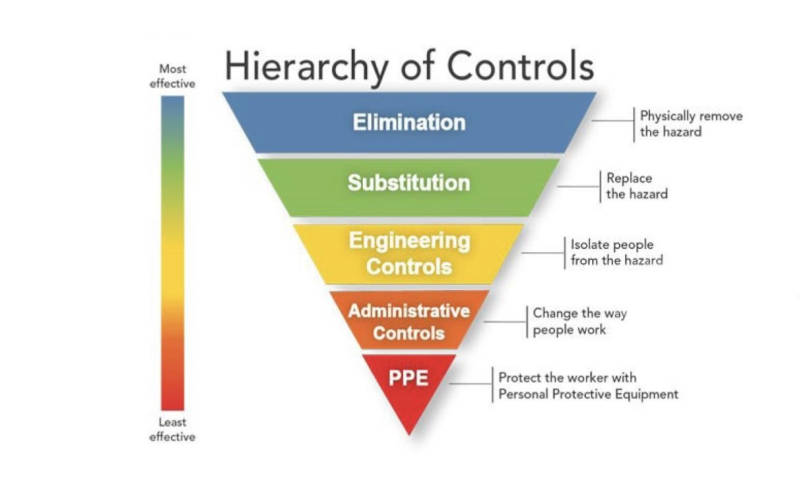

Author Information Joseph Weigel is a product manager for Square D Services marketing. He has been very involved in the development of the Arc Flash Safety program for Schneider Electric to educate customers on emerging arc flash safety standards. Weigel is also very knowledgeable about services retrofit products, and application of engineering controls to enhance the safety of electrical workers. The Bottom Line…

Switchgear and switchboards provide distribution and protection to various types of electrical load equipment in a facility.

Typically, regularly scheduled maintenance has not been a primary concern in most facilities.

Switchgear and switchboard components such as overcurrent protective devices are fundamental to the task of protecting the system as well as reducing hazards for electrical workers.

Retrofit options are now available to extend the life of existing switchgear, which could be a more cost-effective choice for some facilities.

Electrical switchgear has two types of components — passive and active — that make up the system.

The retrofill process is often used in lieu of direct replacement for larger devices such as main breakers and tie breakers.

Power contracts awarded

Contracts for a power grid development in Qatar and wind turbines in Scotland have been awarded to Siemens.

Siemens Ltd. recently announced that it, along with its parent company, Siemens AG, have won a contract worth 40 billion rupees for a power grid development project in Qatar. The project, which must be completed in 22 months, will involve supplying 25 new substations and providing extensions or renovations of 24 existing ones.

“This mega contract from the Qatar General Electricity and Water Corporation is the largest ever contract won by Siemens in transmission and distribution segment worldwide,” said Siemens officials.

The Whitelee Wind Farm, which will be located south of Glasgow in Scotland, United Kingdom, will receive 140 wind turbines as part of a contract recently awarded to Siemens Power Generation by the utility Scottish Power. Whitelee will be Europe’s largest wind farm with an installed capacity of 322 MW — sufficient to supply electricity to about 200,000 households in Scotland. The Whitelee Wind Farm project is the largest wind farm contracted by Siemens Power Generation to date. Total contract value is approximately EUR350 million. Completion of the project is scheduled for summer 2009.

Renewable energy is an integral part of the U.K.’s goal to reduce carbon dioxide emissions. The British government has set a target of 10% of electricity supply from renewable energy by 2010.

ABB has been awarded a contract to supply a 500 kV static VAR compensator (SVC) for Allegheny Power’s Black Oak Substation in Western Maryland to improve reliability on the PJM electricity system. The contract, scheduled for completion by the end of 2007, is the largest turnkey SVC contract ever awarded in the U.S.

An SVC is power electronics equipment that provides fast-acting reactive power compensation on high-voltage electricity transmission networks. SVC technology increases transmission capacity and stabilizes power supply and is also a vital part of the transmission system for maintaining reliability during various system conditions.

“Allegheny is committed to relieving transmission congestion to better serve its customers and ensure the stability of the transmission system,” said Michael Barnoski, head of ABB’s North American Power Systems division. “This technology is in strong demand by utilities as they seek to improve reliability and improve performance of existing assets.”

Allegheny Energy is an investor-owned utility with a balanced portfolio of businesses, including Allegheny Energy Supply Company, LLC, which owns and operates electric generating facilities in the Mid-Atlantic region of the United States, and Allegheny Power, which delivers low-cost, reliable electric service to about 1.5 million customers in PA, WV, MD and VA.