In the Plant Engineering state of the industry report, several trends affect plant managers and industrial experts.

Manufacturing trends and insights

- Supply chain delays, not enough people on a project and lack of training top the challenges plant engineers are experiencing right now.

- Technology trends are carefully watch at industrial or manufacturing plants.

We recently conducted a study of the Plant Engineering audience, and the results are fairly interesting. Nearly 200 people gave feedback on a variety of topics, from their primary role at work to where their company stands versus competitors to challenges at work.

The challenges are vast. Many cannot be controlled, which makes it exceptionally difficult to plan ahead or make business decisions. Take supply chain delays, for example. When asked, “What are some engineering challenges you are currently experiencing or have encountered in the very recent past?,” 64% said they experienced supply chain delays. And when asked, “What are the current trends and challenges facing the engineering industry?,” 67% indicated they experienced supply chain problems obtaining raw materials.

According to Deloitte’s 2023 Manufacturing Industry Outlook, supply chain delays continue to be one of the top challenges in 2023. They reference exactly what Plant Engineering respondents did: Sourcing bottlenecks and logistics backlogs.

And a KPMG report provides ways to mitigate these supply chain issues, though not all manufacturers or businesses will have the ability to adjust quickly.

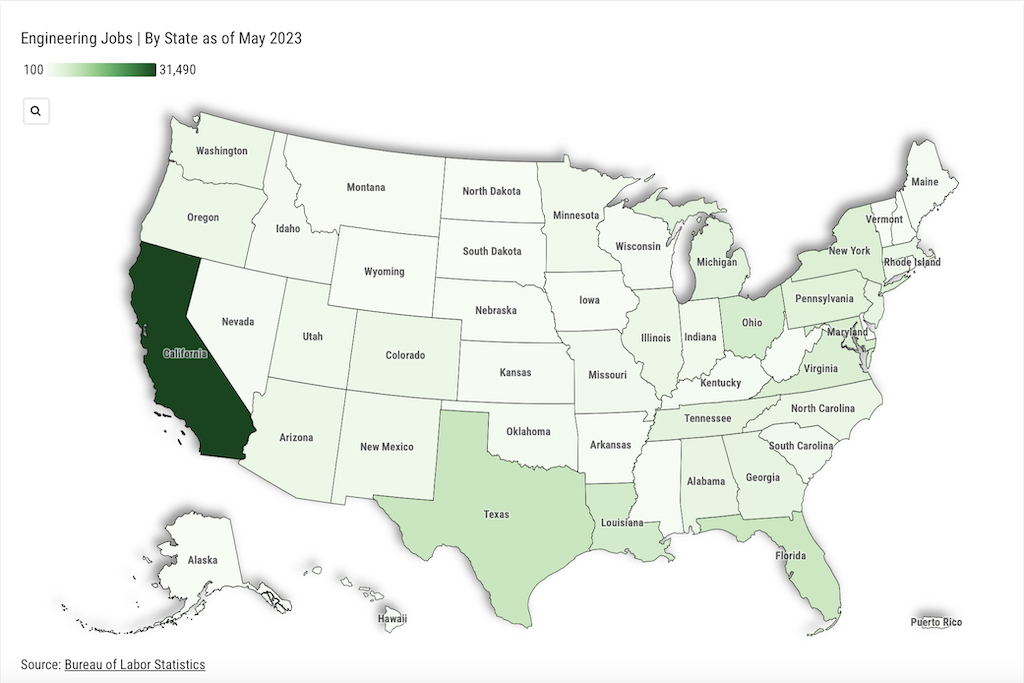

Some of these supply chain issues are directly connected to the second engineering challenge: not enough people working on a project (46% indicated this was an issue). Finding talent is a problem in many industries, and the manufacturing and industrial sector is no different.

Cross-training and using technology like artificial intelligence (AI) could help mitigate some of the staffing issues, though it’s not an instant fix. In the case of the Plant Engineering study respondents, 63% see AI as a way to “remove tedious or repetitive tasks.” On the flipside, 63% of respondents said new graduates need people skills just to thrive in the current landscape.

So where does that leave workers, both those fresh out of school and the more seasoned employees? The majority (66%) feel their company is ahead or just pulling ahead of the competition. Many (49%) say that “increasing complexity of projects and systems” is a trend that others should watch.

Finally, the manufacturing industry is adapting to the changing needs and expectations of clients in many ways:

-

Offering customizable and scalable solutions: 45%

-

Emphasizing sustainable and environmentally friendly practices: 41%

-

Implementing agile project management methodologies: 34%

-

Providing comprehensive life cycle support and services: 34%

-

Leveraging innovative business models and partnerships: 31%.