Innovations in technology and AI, along with increasing demands for sustainability, are pushing businesses to adopt asset life cycle management systems, which are becoming a necessity.

Learning Objectives

- Learn and understand why asset life cycle management (ALM) has grown in prominence and the three trends supporting it.

- Understand what ALM can do compared to enterprise asset management (EAM) and how it can help improve facility management and equipment.

Asset life cycle management insights

- There is an industry-wide shift from enterprise asset management (EAM) to asset life cycle management (ALM), which is being driven by innovations in technology, the rise of AI and emerging sustainability regulations on sustainability.

- The result is systems that go well beyond traditional planning, tracking and execution of maintenance now have a sophisticated focus on extending an asset’s overall lifespan and increasing its efficiency.

- The tailwinds behind ALM suggest this trend will continue for the foreseeable future, as further advances in technology and AI make ALM more accessible and valuable for organizations of all sizes.

Turning a car key in the ignition often prompts a lighted dashboard that shows the air pressure of each tire, the miles driven since the last oil change, whether the doors and trunk are properly closed, and more. This sort of everyday asset life cycle management (ALM) monitors key parts of the car, helps maintain the overall system, maximizes its lifespan and minimizes the time you’re left frustrated on the side of the road.

When it’s a business with three offices, six factories, a fleet of vehicles for transport, hundreds of dispersed workers and a constant need for electricity, heat, fuel, equipment, spare parts, and more, it is not hard to see how valuable ALM is—and how this value grows at scale.

ALM has been grabbing the spotlight from enterprise asset management (EAM) offering a more comprehensive view that considers asset planning, operations, performance, and the entire strategic life cycle. This includes acquisition and/or replacement, risk calculations, maintenance and utilization costs and investment planning.

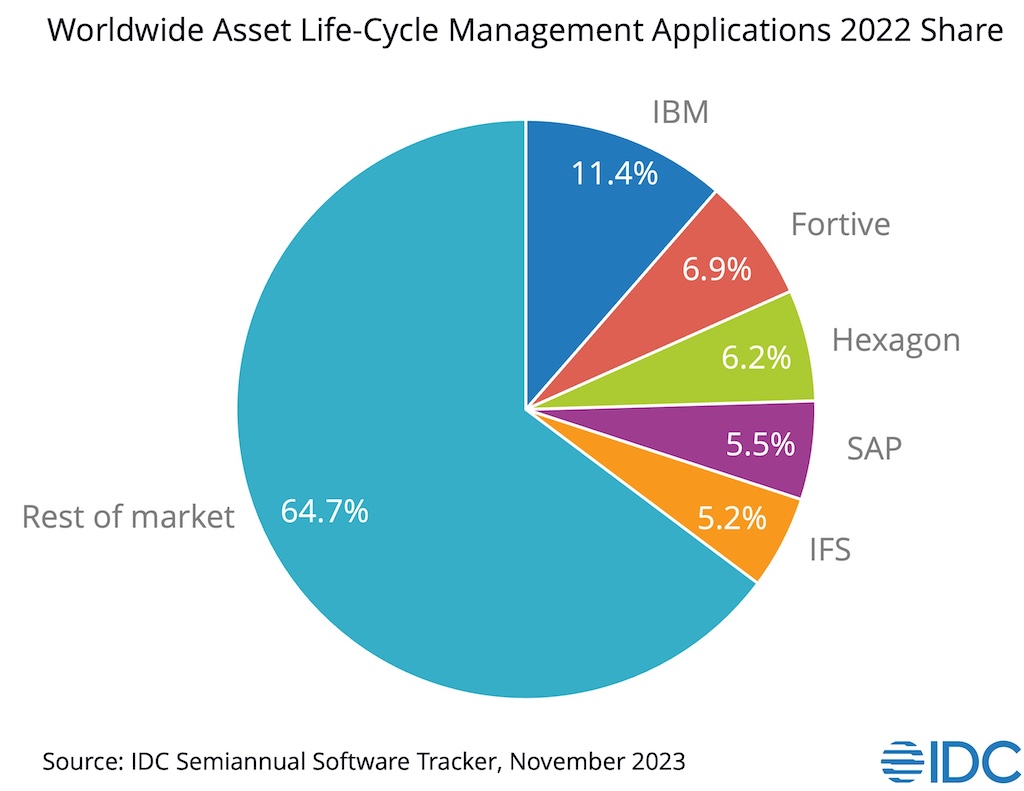

Last year, market intelligence firm IDC chose to replace its market analysis of EAM with ALM. The landscape and players may look similar—IBM leads with an 11.4% share, and four others join it to collectively make up a third—but the update reflects a watershed moment for the industry.

How technology, sustainability and AI are helping ALM grow

ALM is becoming a more powerful need among businesses. The same IDC report shows some still fear economic uncertainty and lower technology budgets may impact the market’s growth, along with risk factors like inflation and staffing. However, three broad trends suggest ALM is primed to grow.

-

Technology. Data is the lifeblood of ALM, and new technologies are expanding the breadth, speed, and accuracy of that data every day. Workers are using phones, tablets, and more to make inspections quicker and more accurate. Robots and relatively low-cost drones can venture into dangerous or previously inaccessible environments—like mines, bridges, oil rigs, and more. These advances mean users can collect more data faster and safer on a regular basis. More accessible data sources also can now be connected to a cloud-based “Internet of Things (IoT)” and be collected in near-real or real-time. This increasing quality, consistency and availability of data makes ALM more possible, valuable and critical to an organization’s effectiveness and competitive edge. Technology is also helping ALM expand talent and extend its reach. Mobile workforce apps are helping to improve productivity in the field, automate scheduling, contribute to regulatory compliance, and assist less experienced workers. Field service and maintenance managers can also use the data to analyze, understand and experiment with assets in previously impossible ways, improving understanding and enabling better and more timely decisions if and when real complications emerge.

-

Sustainability. Among the sustainability regulations emerging worldwide are the European Union’s Corporate Sustainability Reporting Directive (CSRD), California’s recent laws on disclosing climate risk and emissions, and the SEC Climate Rule. ALM has an important role to play in this space by helping drive sustainable operations and enabling accurate, efficient reporting across various frameworks. By optimizing equipment performance, minimizing waste through efficient maintenance practices and retiring outdated assets, ALM helps reduce the ecological footprint of organizations. That includes helping reduce emissions intensity and cutting costs and emissions associated with needs that stem from unexpected downtime or need for parts and repairs.

-

Artificial intelligence (AI). AI and machine learning (ML) advances are allowing organizations to better leverage new and existing data. Manual analysis can become more challenging with more and more granular data. However, AI models can pull and aggregate data from countless sources, even going beyond traditional data sources by, for example, pulling from videos and other unstructured data. This can not only collect the “institutional knowledge” of engineers and operators, but also uncover previously unseen patterns that predict failures in new ways. AI also can uncover useful insights and apply them to scheduling work, managing supply chains and inventory and prescribing maintenance in pathbreaking ways.

How ALM has gone from nifty to necessary

According to IDC, 56% of the market today either run their assets to failure or practice traditional, time-based “preventive” maintenance. This is the equivalent of checking a car’s tire pressure every six months. At best, it’s a waste of time. At worst, the wheels are being damaged and getting the car bad fuel efficiency. The consequences are much worse than that for businesses.

Dr. John Moubray, a pioneer in reliability-centered maintenance (RCM), estimated as much as 70% of the investment in preventive maintenance has no effect on asset up-time metrics. He suggested time-based overhauls can even introduce problems in an otherwise healthy system.

Another 30% of the ALM market have taken things a step further, practicing “predictive maintenance” that is based on monitoring the asset’s condition and performance. Rather than waiting until a failure, predictive maintenance can help address problems once they become visible in the data.

The final 14% have advanced to “prescriptive maintenance,” where predictive maintenance is augmented with AI. This future looks like a trusted, digital adviser that is constantly planning, analyzing and assisting the user. Automated scheduling is shifting to AI-driven “smart” scheduling. Hand-held inspection apps are being bolstered with augmented reality/virtual reality (AR/VR) capabilities and serving as portals to robots and drones in the field. An AI adviser can point out outliers or trends as they pop up and recommend different strategies to solve the problem or boost cost efficiency.

ALM has always existed in one fashion or another, but today’s networked, AI-powered systems can reduce downtime, costs, waste and emissions in ways they couldn’t before. As ALM becomes more widely accessible to organizations of all sizes—and as technology, sustainability and AI continue to make ALM more impactful—what was once a competitive edge is quickly becoming a baseline necessity.