The Department of Technology at Illinois State University (ISU) is training students to program and operate industrial robots in preparation for careers in industry.

Illinois State University in Normal, Ill., is a proven industry leader using ABB robotics and software to train tomorrow’s workforce, which will be using robotics in many different industries and applications.

The Department of Technology at Illinois State University (ISU) trains students to program and operate industrial robots in preparation for careers in industry.

The rapid increase of robot orders by U.S. companies requires people to have the skills that enable them to operate and maintain robotic products, systems, and software. Academic institutions play a significant role in the job market. To meet the rising demand, universities and technical colleges are investing in robotics to further prepare their students for the future workforce.

ISU has partnered with ABB Robotics to provide a training program with industry-leading technology and curriculum support. Current and future ISU students will graduate with the skills they need to succeed in the future of industry and robotic automation.

The changing landscape in education

As robotics and industrial automation are on the rise, so is the demand for engineers and qualified technicians in the industry. The U.S. has seen a significant growth in demand for robots as companies look for ways to meet the challenges caused by a rising shortage of available labor.

According to figures from the Association for Advancing Automation, almost 40,000 robots were sold in the U.S. in 2021, with non-automotive companies in sectors such as metals, food and beverage, plastics and rubber and others accounting for 58% of the total demand. In many cases, these companies are using robots to handle jobs that are dirty dangerous, dull, and hard to fill due to the lack of skilled labor.

“One trend that I think we’re seeing clearly is an increased demand for our graduates, said Dr. Kevin Devine, College of Applied Science and Technology Professor, Department of Technology, ISU. “The industry is clamoring right now for qualified people and we’re having a lot of trouble meeting that need.”

Educational institutions are emphasizing focus on science, technology, engineering and mathematics (STEM) subjects so that current and future generations are able to solve the most pressing problems in industry and help create a more sustainable future.

ISU’s investment in robotics has proven to support student innovation, creativity, and technical advancements. Their program has attracted students from around the world and re-invigorated the classroom experience through their ABB supported robot lab and offline programming tools.

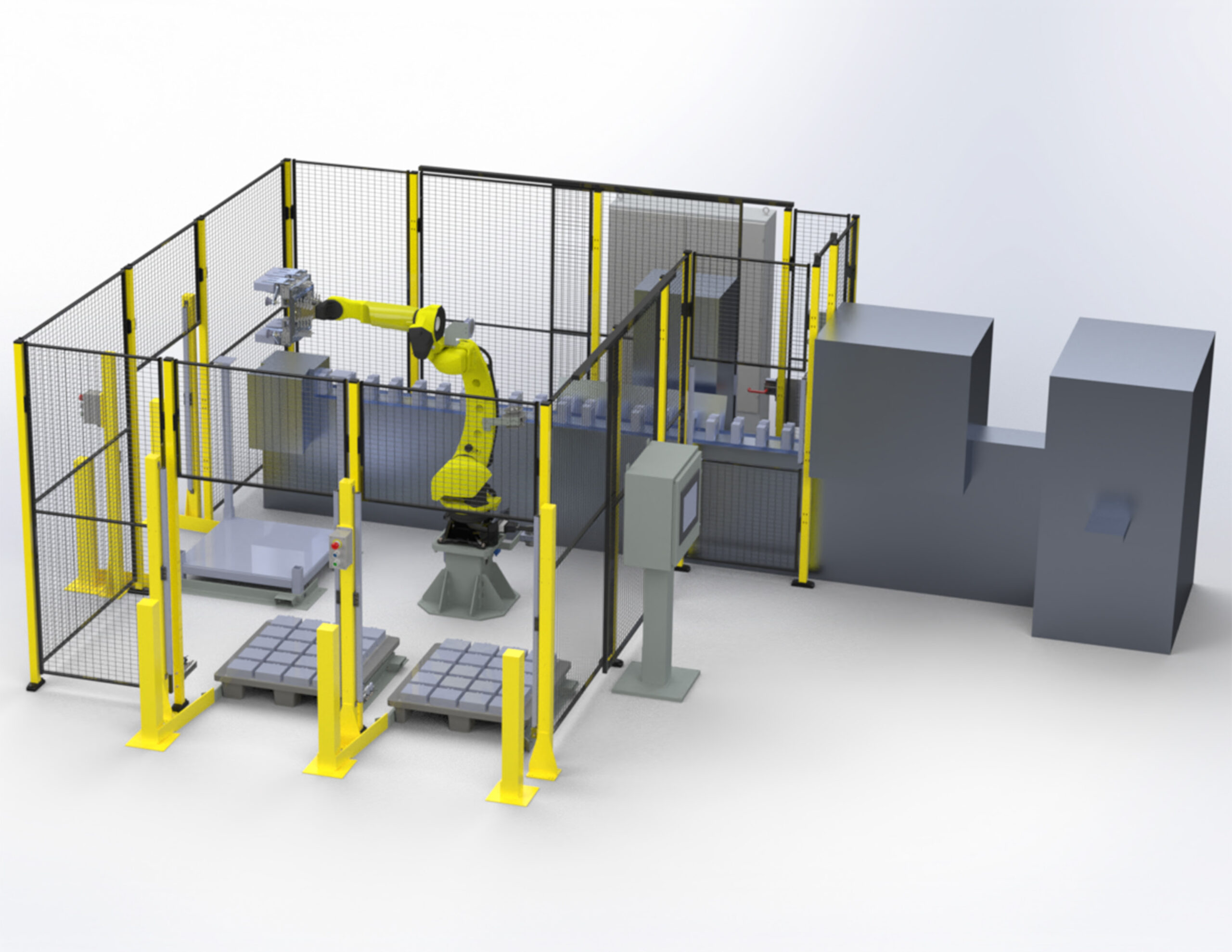

“We give our lab the feeling of a training environment to resemble the workplace,” said Professor Jeritt Williams, Department of Technology at ISU. “We have a work cell with authentic equipment, materials, and real-world situations that they’ll be using in their careers.”

The lab features an array of ABB robots and software to provide students with the experience and knowledge of Industry 4.0 and smart manufacturing technologies. One of the tools available is their offline programming software, which enables different robotic solutions to be created and simulated in a virtual environment before applying them in the real world. ABB offers up to 100 licenses free of charge to universities and colleges.

Training for educators

The key to the effectiveness of the teaching program is ABB’s Software, Maintenance, and Robotics Training (SMART) certification program for STEM. This program certifies educators to effectively implement, teach, and certify their students on ABB’s curriculum.

The program guides educators through the tool with hands-on examples and interactive labs that boost student engagement and success. The SMART certification program enables ISU’s staff to access ongoing training and help enhance their own knowledge.

“I have been impressed with the quality of the technical support and training provided by ABB,” Devine said. “I have attended three training classes conducted by ABB and learned a great deal in each class. “If I have questions about anything, technical support personnel are glad to help.”

– Edited from an ABB Robotics press release by CFE Media and Technology.