Siemens Energy & Automation Inc. has enhanced Version 7 of its SIMATIC PCS 7 Process Automation System to include a comprehensive set of easy-to-use advanced process control (APC) capabilities. The APC improvements include PID enhancements such as auto-tuning and gain-scheduling, predictive control, fuzzy logic and neural network control.

Siemens Energy & Automation Inc. has enhanced Version 7 of its SIMATIC PCS 7 Process Automation System to include a comprehensive set of easy-to-use advanced process control (APC) capabilities.

The APC improvements include PID enhancements such as auto-tuning and gain-scheduling, predictive control, fuzzy logic and neural network control. The system also offers control performance monitoring, including statistical analysis of process variable, control error and manipulated variable.

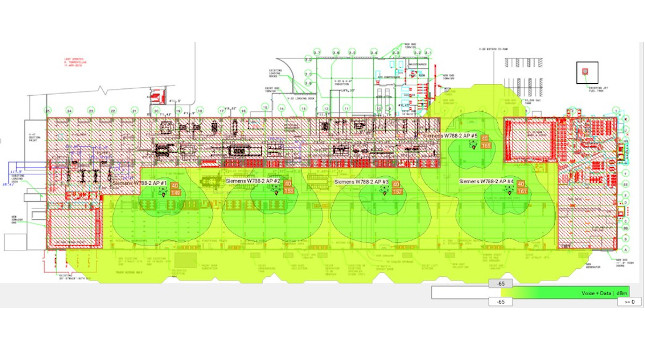

APC functionality is delivered by a set of embedded function blocks, which run in the controller along side standard logic with pre-built faceplates for operation and monitoring through the HMI.

Version 7 integrates new and existing automation systems (process, batch, discrete and safety) and devices (instrumentation, analytics, motors, drives and safety instrumented functions) within a single platform.

Capabilities include configuration/change management, redundant fieldbus with safety communication, integration of Foundation Fieldbus, smart alarm management, plant asset management and condition monitoring.