Robots have the ability to go where we can’t and perform jobs we shouldn’t including applications such as chemical refining and hazardous material handling and subzero palletizing.

Robots perform dull, monotonous jobs every day. While this was their traditional domain, they are capable of so much more. Productivity, quality and efficiency have moved to the forefront. Return on investment (ROI) is now often measured in months, not years. Volume is not as critical.

With more focus placed on the gains, sometimes we forget what we save. The freedom from extreme temperatures, strenuous payloads, harsh chemicals and toxic fumes. Robots have the ability to go where we can’t and perform jobs we shouldn’t. From chemical refining and hazardous material handling, to toxic drug compounding and subzero palletizing, robots’ superhuman capabilities take them to extremes.

Robotic furnace tapping

Furnace tapping is a grueling job. The heavy lifting is repetitive and physically demanding. Temperatures are hot enough to melt metal. Noxious fumes and toxic dust make the task dangerous for humans. But for robots, and an experienced automation integrator, furnace tapping is no sweat.

Specialized Analysis Engineering, Inc. (SAE) is an engineering services firm with expertise in industrial automation, robotics, process controls, systems integration, fabrication and wiring. The Logan, Utah-based firm has completed projects across a wide spectrum of industries including arc furnace tapping automation for phosphorus reduction furnaces and steel smelting furnaces.

SAE has automated six furnace tapping cells for a phosphate refining facility owned by Bayer. The facility operates multiple electric arc furnaces to produce elemental phosphorus for herbicides.

During the refining process, a waste product is created in the form of molten slag that approaches 1650°C, hot enough to melt steel. This molten slag must be periodically removed from the furnace in a process called tapping. During the tapping process, the environment around the arc furnace is extremely harsh. Extreme high temperatures, the potential for splashing molten material, and noxious fumes and vapors make it hazardous for humans.

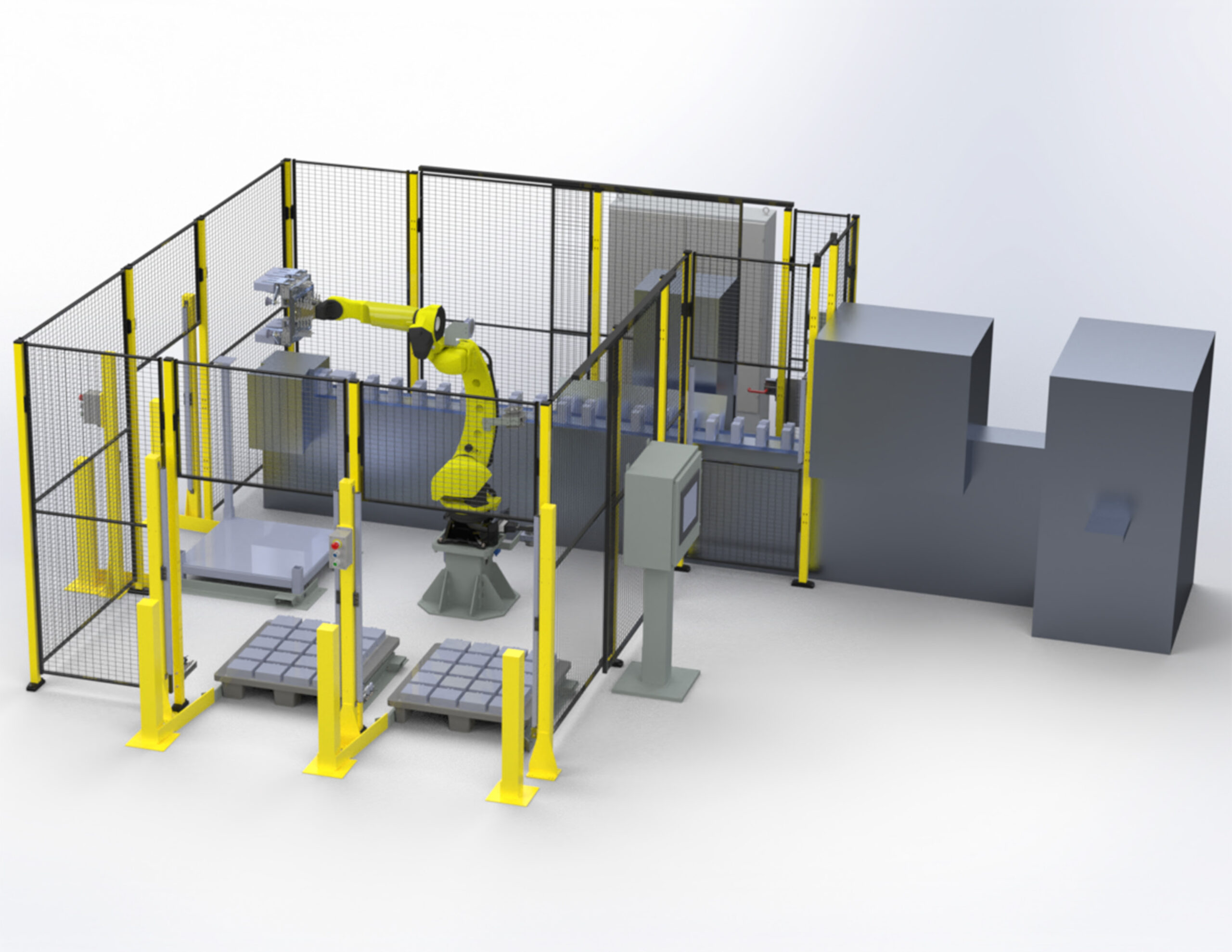

The operating environment is so extreme that even the robot needs protection. Under the metallic cover is a heavy payload robot inverted on a custom-built 7th axis positioner with coordinated motion. Inverted mounting allowed room for other activities in the workspace that would have been prohibited by a floor-mounted configuration.

Takes the heat, lightens the load

The robot must be able to operate in ambient temperatures that vary from -29°C during Idaho winters to over 38°C in the summer. To handle high ambient temperatures and the extreme process environment, the robot is protected by a heat-resistant armor made by Roboworld. SAE engineers worked with Roboworld to have their robot armor customized to accommodate the inverted mounting position and the accessory equipment required by this application.

Tool changers and an automated tool rack allow an invert-mounted robot to perform multiple furnace tapping tasks without operator intervention. Courtesy: Specialized Analysis Engineering, Inc./Robotic Industries Association[/caption]

Prior to automation, this furnace tapping process was entirely manual. It required operators to have a certain level of strength and stamina to perform repetitive tasks with heavy and cumbersome tools. By integrating a robotic system, it creates job opportunities for people who would otherwise be physically incapable of performing the previously manual tasks. The robot is also able to manipulate tools that are much heavier, more robust, and have a longer lifespan than the previous manual tools used by human operators to perform the same work.

Each of the six robotic system installations were unique to each location within the phosphate refining facility, requiring SAE engineers to design extensive structural modifications to the building and the robust mounting structures required to support these 680-kg robots. The first robot was installed in February 2013. Additional systems were installed over the next few years, with the most recent, sixth robotic installation completed in October 2018.

Building industrial batteries

Heavy payloads and molten lead are no match for this heavy-duty robot helping to build industrial batteries. Neither is airborne lead dust, a health hazard for human workers.

When Battery Builders Inc. (BBI), a Naperville, Ill.-based manufacturer of industrial lead-acid batteries for lift trucks and other electric-operated equipment, decided to upgrade their facility, they got way more than expected from their new robot. They would more than double production with less labor, improve product quality, and reduce health and safety risks.

Frustrated by costly production delays caused by antiquated equipment, BBI worked with MAC Engineering from Benton Harbor, Mich., to replace their 25-year-old cast-on-strap (COS) machine. MAC also integrated a large payload robot to tend the new six-station COS machine. Automating the machine tending tasks reduced the number of workers from seven to five people and freed them up for more high-value tasks in other areas of the manufacturing facility.

The robotic process starts with the robot precisely aligning groups of vertically stacked battery plates, making sure the edges are even and flush. Then the robot picks up the plates and runs them over a large bristle brush to remove any lingering debris from the end connectors, or lugs. Next, the robot runs the product through a flux process, which prepares the metal lugs by removing metal oxides that could form beads when heated. The lugs are then dipped into tin to establish a stronger connection, and then dipped again into molten lead to connect the plates and establish the positive and negative posts. Finally, the robot places the battery plates into the last station, which automatically inserts the plates into a molded plastic casing.

BBI needed to consistently align 136 kg of battery plates up to 500 times per day. The large payload robot they integrated has a 300 kg payload and combines a long reach of 3230 mm with a minimal amount of dead space for a wide work envelope in a small footprint. High repeatability (±0.3 mm) makes it ideal for applications requiring precision and heavy lifting. Combined, these features enable the robot to reach multiple machines at varying heights, while generating a more consistent product.

During the multi-step COS process, the robot EOAT only needs to change when the battery type is modified. When it’s time for a different battery type, an operator changes the gripper on the robot.

Higher production, lower risk

Although increased production was BBI’s primary goal for the upgrade, the manufacturer experienced unforeseen health and safety benefits. Manually stacking the battery plates and loading them into cases generated more airborne lead dust and posed a greater risk for exposure than the new automated process. The old process also required employees to lift heavier loads, resulting in a greater risk of injury.

For BBI, it was important to see automation’s positive impact on not just their bottom line, but also on their employees’ work environment.

Any airborne lead dust that is created during the automated process is immediately captured by a local exhaust ventilation system and deposited in a HEPA-filtered dust collector. Any residual lead dust that collects on the robot’s surfaces is removed during BBI’s daily housekeeping routine with a HEPA-filtered vacuum and wet wipe-down. The robot wrist and base are rated IP67 and IP65, respectively, and are dust tight.

Since replacing their old COS machine, BBI has experienced better, more consistent product quality using fewer worker hours. Employees who used to operate the old machine are now working in the battery assembly department, allowing BBI to focus more staff hours on the final stages of battery assembly and ultimately improve the overall quality of their batteries.

Automating the manufacturing process reduced the operators’ exposure to airborne lead dust and the amount of heavy lifting their roles require, resulting in a significantly safer work environment. Once all of the integration is complete, BBI expects to increase production from 400 to 1,000 battery cells per day – more than double their output before automation.

Robotic automation is taking on an ever-increasing role in the healthcare industry, too. They go where traditional surgical tools can’t. In the pharmacy, robots are going where humans shouldn’t.

Handling hazardous drugs

Every year, 8 million U.S. healthcare workers are potentially exposed to hazardous drugs, according to the National Institute for Occupational Safety and Health (NIOSH). Chemotherapy, cytotoxic and oncology drugs used to treat cancer, as well as arthritis, multiple sclerosis and other non-cancerous medical conditions, can pose the greatest risk. NIOSH studies have shown that healthcare workers exposed to chemotherapy drugs have increased risk for cancers, chromosomal abnormalities, and reproductive harm.

Heightened concerns over the safe handling of hazardous drugs, a changing regulatory environment, and overall pharmacy efficiency and patient safety have focused more attention on automation. ARxIUM, a developer of pharmacy automation solutions based in Buffalo Grove, Ill., developed the RIVA fully automated IV compounding system.

RIVA is used by hospital pharmacies to automatically and accurately prepare IV solutions in syringes and bags. By automating the process, RIVA improves safety for the patient and the pharmacy technician.

Safer and faster

Automating the repetitive and complex tasks required for preparing IV bags and syringes reduces the incidence of contamination and human error. RIVA also ensures that hazardous and non-hazardous doses are accurate for pediatric, neonatal and adult patients. The system adds efficiency to the compounding process by allowing more doses to be prepared simultaneously.

A robot cycles the drug products from station to station through the RIVA compounding system. The speed at which the robot can move items through the process contributes to the system’s impressive throughput. The entire system is enclosed aseptically in an ISO class 5 environment in order to adhere to the strict levels of sterile cleanliness required for IV compounding.

Technicians have the flexibility to run only single daily shifts or some run the system 24 hours a day, seven days a week. To date, ARxIUM has integrated over 50 robots and controllers exclusively for RIVA compounding systems. More than 8 million doses have been filled by RIVA systems.

The robots help the RIVA system enhance patient care and pharmacy efficiency by improving the safety and accuracy of IV admixture compounding. In 2018, healthcare research firm KLAS named the RIVA automated IV compounding system the Top IV Robot for the sixth consecutive year.

Heavy lifting in arctic conditions

Albertsons, a large grocery chain based in Boise, Idaho, with stores across 35 U.S. states, needed a new automation solution for their cold packaging operation. The palletizing robot would need to satisfy very specific speed, payload, flexibility and footprint requirements. It would also have to withstand arctic-like conditions with food-grade chemical washdowns that could strip paint off a car.

After searching the market, Albertsons chose a five-axis robot designed to perform palletizing tasks quickly and precisely even in ice cold temperatures as low as -30°C. Thanks to the Arctic design, it needs no protective suit. A narrow base and substantial reach allows for short cycle times and high flexibility when stacking items in frosty environments with limited floor space.

Robots rush in where others dare to tread. They do not fear the grueling, hazardous, and toxic tasks that are dangerous and potentially fatal to humans. They go where humans cannot and not only make the workplace safer, but better.

Tanya M. Anandan is contributing editor for the Robotic Industries Association (RIA) and Robotics Online. RIA is a not-for-profit trade association dedicated to improving the regional, national, and global competitiveness of the North American manufacturing and service sectors through robotics and related automation. This article originally appeared on the RIA website. The RIA is a part of the Association for Advancing Automation (A3), a CFE Media content partner. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].