Collaborative robots (cobots) can improve weld times and inefficiencies on the plant floor.

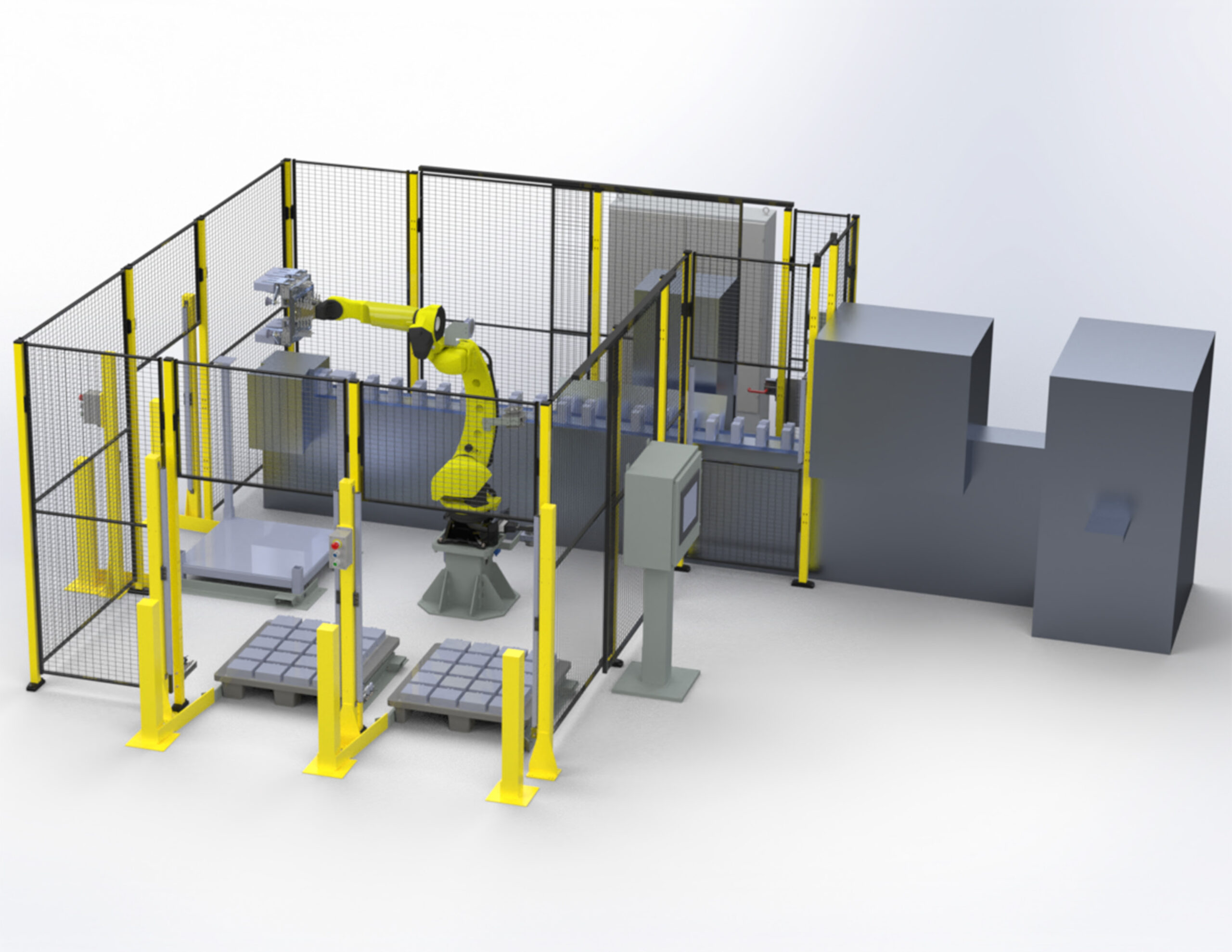

Collaborative robots (cobot) have been around for more than 15 years, and recent sensing and motion control technologies are improving quality while reducing weld process time on a 30-pass weld by more than 80%. With such advances in collaborative robot welding, in-demand skilled welders can shift focus to weldments requiring more human finesse. Collaborative robot use in the welding industry has exploded, largely due to the ease of programming, versatility and affordability systems offer, helping fill the gap between manual welding and traditional robotic welding cells. The shortage of skilled labor was present even before the COVID-19 pandemic and recent supply chain struggles and has become more acute during recent years, further fueling fabricators’ need for simple, flexible automation tools.

Cobot welding systems began by working on easy weld tasks, like simple welds on repetitive and consistent steel parts, typically with smaller weld wire diameters. Recently, cobot welding system integrators like are enabling a broader range of weld applications through the development of new configurations and technologies on their cobot welding platform. These new developments include heavy-duty packages for welding with larger weld diameters (up to 1/16 inches or sometimes larger), push-pull packages for welding aluminum and other soft wires, various deployment options that add versatility and software features like touch sensing, multi-pass and through-the-arc seam tracking. Each of these evolutions enables more types of applications in a fabrication shop, such as heavy weldments, larger parts, various materials and components where automation-level upstream production consistency cannot be maintained.

Using a cobot to improve inefficiencies

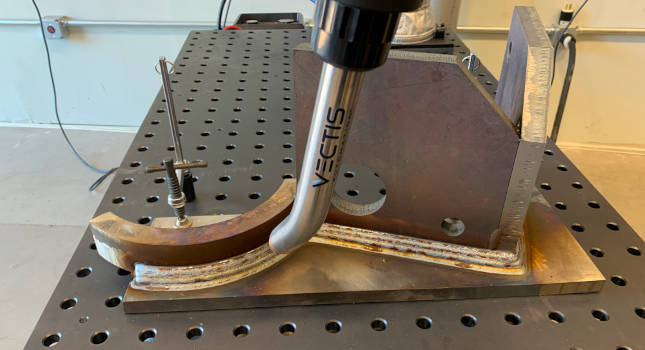

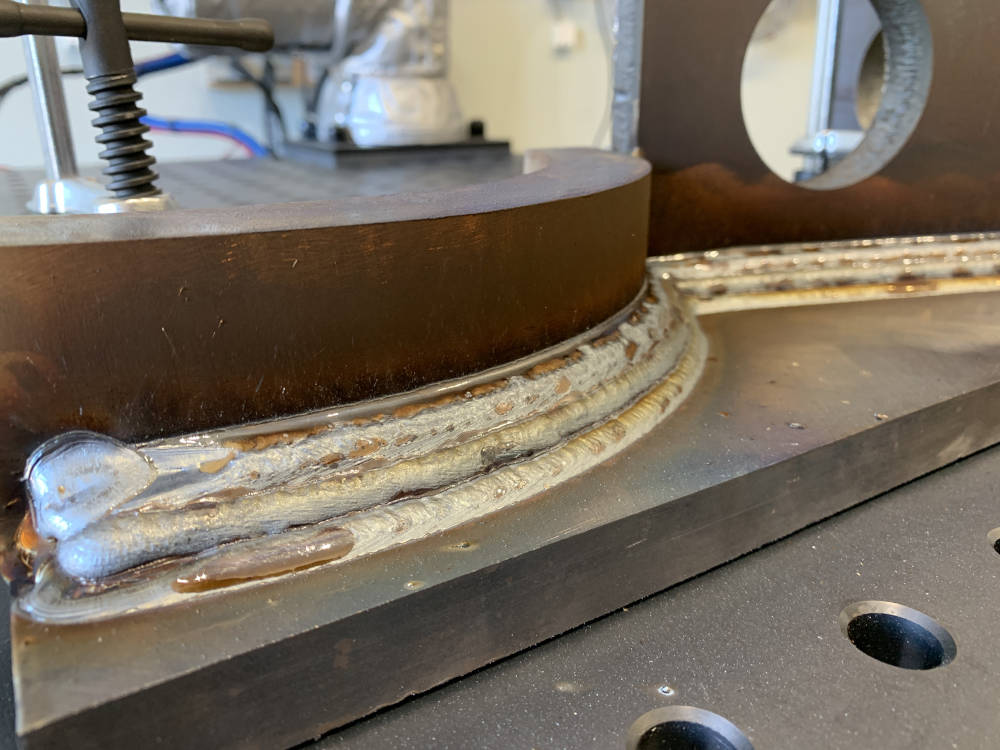

Managing production inconsistencies is a key need for numerous manufacturers, particularly those doing large weldments. Even with upstream improvements, such as lasers, computer numerical control (CNC) press brakes, etc., and better fixturing, inconsistencies still exist in the weld shop. A through-the-arc seam tracking feature for a collaborative robot welding tool helps manages variations Through-the-arc seam tracking technology enables path correction during live welding by monitoring and using welding arc electrical characteristics to adjust the cobot path in microseconds. The feature enables automation use on applications that were inconsistent, like with plates that distort while welding and assemblies where slot-and-tab construction isn’t viable or where precision fixturing would not be economical. The tracking technology allows cobots to tackle heavy-plate weldments. These weldments tend to have inconsistencies due to the nature of their construction and the potential for more distortion during welding.

The tracking adjusts the cobots programmed path based on an ongoing comparison of those readings, improving quality and consistency, especially where impossible with upstream processes and fixturing (such as distortion on heavy-plate parts). The seam tracking feature can correct both contact-tip-to-work (“CTWD,” “stickout”) distance and steer the cobot to stay in the center of symmetrical joints An algorithm correlates a cobot correction path in the joint at the proper tip-to-work distance.

Control system design for robotic motion

The control system design for the tracking system integrates robust and speedy electrical arc parameter readings, components that can sense minute variances in high-amperage circuits, filtering algorithms to manage the various waveforms of the weld arc, fast data-crunching to determine where to steer the cobot in real-time and all the while making sure it is easy to use for the customer.

The through-the-arc seam tracking technology can also be used in conjunction with Vectis’ multi-pass software to correctly offset subsequent weld passes using the root pass that was seam-tracked. When combined, this technology combo has enabled productivity gains for heavy weldment fabricators. As cobots become more prolific in the welding and cutting market, new technologies like through-the-arc seam tracking will continue to increase the portfolio of viable applications.

Josh Pawley is VP of business development at Vectis Automation.