Focusing on COVID-19 risks in the workplace has shed new light on the benefits of automation and robots and their benefits on the plant floor and manifesting in multiple ways.

As factories come back on-line and essential businesses that never went off-line continue facing daily challenges of operating amidst a global pandemic, attention falls on the health and safety of workers. The U.S. Centers for Disease Control and Prevention (CDC) lists distance between workers and contact with contaminated surfaces as distinct factors that impact workers’ risk for exposure to the novel coronavirus, or COVID-19.

Focusing on COVID-19 risks in the workplace has shed new light on automation’s benefits–especially robots. They are immune to biological viruses; in fact, they kill them. Robots have already proved their mettle as mobilized germ zappers decontaminating hospitals and airports, robot temperature screeners and food delivery bots for quarantined people.

Social distancing with collaborative robots

Collaborative robots, or cobots, for short, are able to safely operate within close proximity to humans. Often used to augment human workers or assume their tasks so the humans can move to more value-added and fulfilling work, collaborative robots have a reputation for raising the human condition.

In the Lone Star State, it’s collaborative robots vs. COVID, as Universal Robots comes to the aid of a small machine shop. All Axis Machining, a metal fabricator in Dallas, Texas, already had a small team of collaborative robots on the shop floor performing an array of tasks, including machine tending, sanding, deburring, and wire EDM. Automating with collaborative robots a couple of years ago increased their spindle run time from 8 to 20 hours a day.

“Now we have just a few people in the shop, and the cobots’ better productivity results in lower operating costs and more manufacturing hours available,” said All Axis owner and CEO Gary Kuzmin. “It’s the best thing I ever did.”

In the midst of the pandemic, All Axis added two more UR collaborative robots to keep their tools at maximum capacity and help socially distance the shop’s manual labor. They also added a weekend shift to disperse staff density. They now have eight collaborative robots running 24/7 across three shifts. The third shift is completely lights-out.

“Cobots allow us to keep employees socially distanced in a way they feel comfortable,” Kuzmin said. “We now have more robots working and minimal crew taking care of non-robot actions. This shift in operations was all driven by COVID and with the help of the cobots, it’s working out very well for us.”

Collaborative robots are also on the job at GE Healthcare, where they help fabricate consumables for ventilators. GE partnered with Midwest Engineered Systems (MWES), an RIA Certified Robot Integrator in Waukesha, Wisc., to help expand their production capacity for ventilators after learning of MWES’ successes in automating precision valve manufacturing for GE’s turbine engine division.

“A lot of our manufacturing customers are seeing that spacing between employees on the production line needs to be farther apart to follow social distancing guidelines. That’s a good application for collaborative robots,” said Peter Gratschmayr, vice president of sales and marketing at MWES. “We are in the process of integrating a couple of UR robots on different subcomponent lines for GE ventilators. The updated packaging line will be able to double ventilator valve production while using less shifts.”

Staggering or interspersing collaborative robots on a production line helps their human coworkers socially distance, in effect thwarting the potential for virus spread. Assembly lines, kitting lines, any situation where workers are typically shoulder-to-shoulder or face-to-face along the production line will benefit from increased productivity as well as enhanced worker safety through social distancing.

Robotic palletizing

As people opt to live, work and play from home during the pandemic, e-commerce is booming. Manufacturers and distribution centers are racing to meet demand. Those looking to boost production and loosen worker congestion on warehouse floors and loading docks are driving the heightened interest in robotic palletizing and depalletizing.

“There’s plenty of opportunity for helping customers with packaging and palletizing for e-commerce,” Gratschmayr said. “We’re also doing more depalletizing. And now we’re doing whole layer picking systems for customers. It helps make it easier for their space utilization as well as spacing between employees. They get increased throughput and social distancing at the same time.”

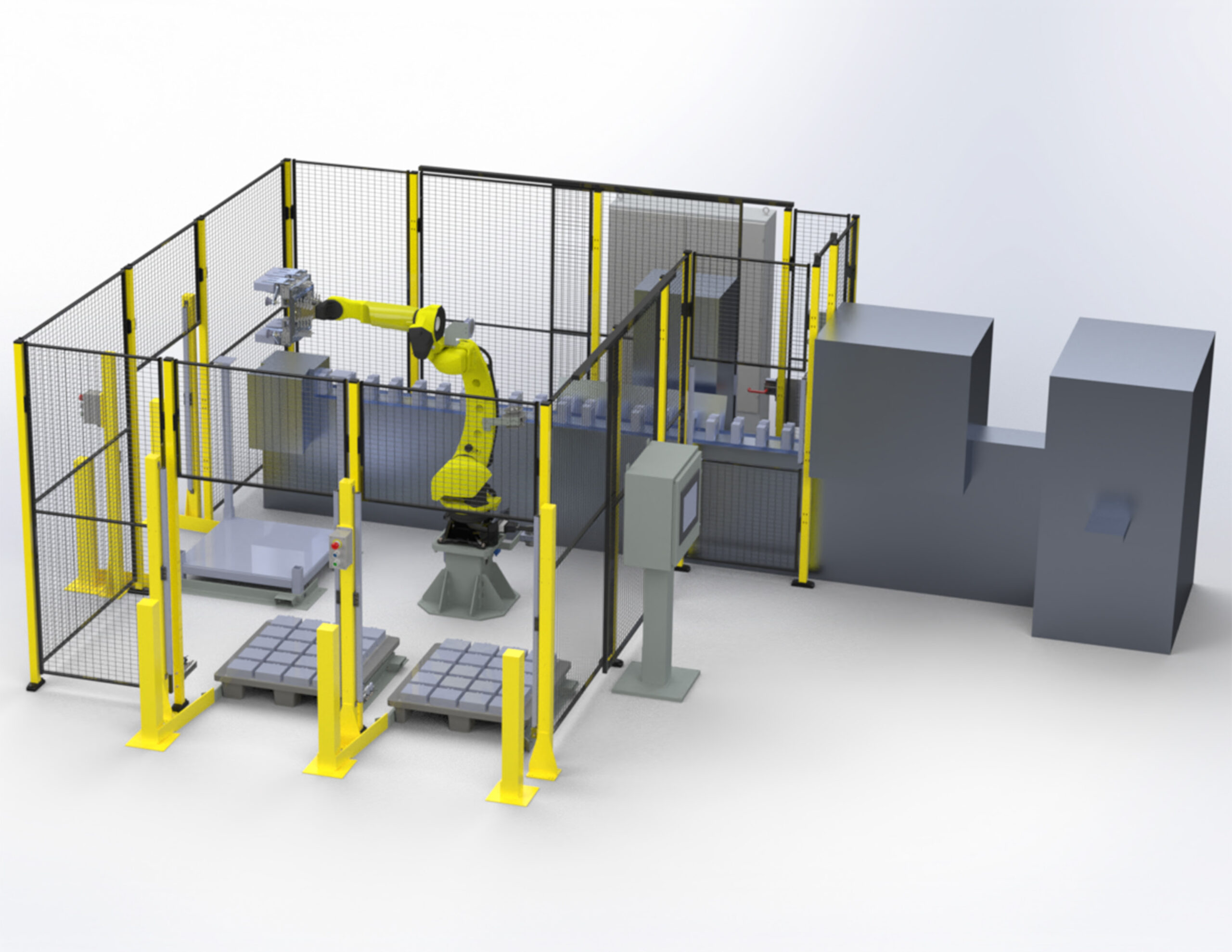

MWES builds palletizer systems with compact footprints and also custom solutions like the 8-axis palletizer. With a Fanuc robot at its core, this system features a 22-meter track for servicing multiple conveyor lines.

Rent a robot

Systems integrator RobotWorx in Marion, Ohio, is also filling orders for palletizing systems. Operations manager Tom Fischer said orders are coming in from companies that had been thinking about automating and decided now is the time.

Others are dipping their toes in with RobotWorx rental program. “Companies are leasing our palletizing systems as a manpower replacement because they either lost people during the shutdowns or they are looking to thin out the density of people in their shops,” Fischer said. “Where they were packing or palletizing boxes by hand previously, they’re now doing it with a robot, at least in the short term.”

RobotWorx leases their Compact Robot Palletizer with no long-term commitment required. Their ready-to-ship robot cells rent by the week, month or year.

Users don’t typically go looking for palletizing systems as a primary method for social distancing, but it ends up being a nice piggyback benefit. Bastian Solutions, a Toyota Advanced Logistics company, is a global material handling and robotic systems integrator based in Indianapolis, Indiana. Matt Kohler, sales manager for Bastian Solutions’ robotics group, said they see more opportunities for palletizing and depalletizing, even for low-volume applications.

“Traditionally those have been accomplished manually, but if you have team lifts or heavier product that requires multiple people, robotic palletizers offer complete autonomy in a warehouse or manufacturing environment. There’s a lot of opportunities there, maybe not traditionally justifiable for labor savings or ergonomic concerns alone, but it now it provides a secondary benefit.”

Fewer touchpoints with robotic bin picking

In addition to social distancing, personal hygiene and wearing cloth face coverings, it’s important to minimize workers’ exposure to surfaces that can become contaminated with the virus. This means reducing touchpoints. Goods-to-robot systems are ready to lend a hand. These advanced technologies use swarms of robotic shuttles to autonomously deliver goods to robotic arms for picking.

“We’re seeing a lot of demand and interest for robotic bin picking, which not only provides labor savings, but also eliminates some high touch surfaces,” Kohler said. “If you think about a bin that may be circulated 10 to 15 times a day to various picking ports, that’s additional touches that each person could have on that particular bin. It’s not necessarily the biggest driver, but there is an ancillary benefit to having a robotic system doing bin picking as opposed to a human.”

Bastian Solutions integrates robot arms by ABB and Fanuc with various automated storage and retrieval technologies, including the AutoStore and Perfect Pick systems. Kohler said these goods-to-robot solutions are mostly used in the e-commerce space and store replenishment for retailers. “We’re in the process right now of executing a project with a Fanuc collaborative arm for a customer.”

But in cases where a goods-to-person system is required, by design, these types of technologies still have a social distancing element. Human pickers are logged into individual workstations usually some distance apart and the goods come to them, so you don’t have pickers wandering the aisles. You can also see where your workers are logged in at any given time, which helps with tracking employee movements through a facility.

Of course these manned stations still need to be disinfected regularly. Robot pickers work 24/7 and virtually eliminate this requirement. The latest wave of goods-to-robot systems and mobile robots are truly the always-on supply chain.

Mobile robots

Robot pickers are at an inflection point. Already on the rise, adoption of autonomous mobile robots is expected to surge even higher. Mobile robots like those from Fetch Robotics and Vecna Robotics promote social distancing by delivering parts to assembly lines, transporting work-in-process (WIP), and managing material handling in warehouses.

Fetch Robotics also has launched autonomous disinfecting robots designed to disinfect up to 99.9% of viruses and bacteria.

InVia Robotics, a provider of mobile robot fleet systems, has added social distancing to its software tools. The new features keep workers at a safe distance from each other and notify both warehouse workers and management if distance is breached.

Remote monitoring and service support

Next-gen technologies are garnering renewed attention during the pandemic. Industrial Internet of Things (IIoT), cloud robotics, Big Data and artificial intelligence (AI) – the smart factory is looking smarter. Robot manufacturers and integrators use these innovative technologies to help customers keep their robotic automation working properly, even if their human caretakers must work remotely.

Preventive maintenance is critical to limit equipment breakdowns, increase performance and efficiency, maximize service life, and safeguard workers from faulty, potentially hazardous equipment. Today’s IIoT technologies put remote monitoring for preventive and predictive maintenance in the palm of your hand.

“Remote monitoring is something we’ve been rolling out through our service group. FANUC has a really nice remote monitoring system that we’ve been implementing,” MWES’ Gratschmayr said, referring to Fanuc’s zero downtime (ZDT) application, which constantly monitors each robot’s mechanical, maintenance and process health – in real-time – and proactively detects potential robot, controller, or process problems before unexpected downtime can occur. Users can even receive notifications via their smartphones.

Gratschmayr said they’re also using industrial connectivity solutions to provide remote access to programmable logic controllers (PLCs). “We’re doing service contracts with our customers, so that their systems are operational and work better for a longer period of time.”

RobotWorx, also deemed an essential business during the pandemic, services government contracts and critical sectors like meat processing. “We’ve seen more demand for our robot support services,” Fischer said. “With the stay-at-home order in Ohio, they shut everything down that wasn’t essential. When everybody had to come back on line, they were having trouble getting their machines up and running. And even essential businesses that shut down portions of their lines in nonessential areas were having issues bringing their lines back up to speed, so our service team was pretty busy during that time. We were doing in-person service calls, a lot of phone support, and we use RealWear.”

The RealWear platform is a hands-free, wearable remote collaboration system that uses a headset camera, microphone and speaker. “Our tech can be on the phone with a computer in front of them, seeing exactly what the maintenance tech is seeing on-site,” Fischer said. “They become our eyes and arms, and we’re able to guide them through the repair.”

RobotWorx has also launched a Facebook group for service and support. Group members can ask questions of the community of RobotWorx techs and experts and get answers quickly. Anyone can join the group, and with many businesses not accepting visitors due to COVID-19 concerns, these types of online communities can serve as a lifeline.

Meatpacking robots

One business sector all too familiar with the impact of the novel coronavirus is the meat processing industry. Meat and poultry packing workers often quarter, debone and sort cuts of beef, lamb, pork and chicken while working virtually shoulder-to-shoulder on assembly lines. COVID-19 outbreaks have forced temporary shutdowns of meat processing plants in more than a dozen countries, including the U.S., Canada, Brazil, Australia and across Europe.

“When there’s an outbreak in a facility, like the meatpacking houses, they’ve contacted us and said they want to automate in order to offset the quantity of employees that they have in their facilities,” Gratschmayr said. “Pork and chicken processing facilities have contacted us for pick, pack and pal applications, and they’re primarily new customers.”

RobotWorx also felt the impact. “We saw a huge uptick in inquiries for meat processing,” Fischer said. “More people are trying to figure out how to prevent a shutdown in the future and what the investment is going to cost them.”

Slaughterhouse workers not only brave bone-chilling temperatures, but also often blistering line speeds with sharp tools and machinery – the 3D’s (dull, dirty and dangerous) – to the extreme.

Fortunately, robots are built for extremes. Extreme temperatures, huge payloads, toxic chemicals and even a global pandemic. Whatever the challenge, no matter the upheaval, robotics and automation aren’t just the future, they’re our best bet for future-proofing manufacturing.

Tanya M. Anandan is contributing editor for the Robotic Industries Association (RIA) and Robotics Online. RIA is a not-for-profit trade association dedicated to improving the regional, national, and global competitiveness of the North American manufacturing and service sectors through robotics and related automation. This article originally appeared on the RIA website. The RIA is a part of the Association for Advancing Automation (A3), a CFE Media content partner. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media, [email protected].

MORE ANSWERS

Keywords: COVID-19, robotics, supply chain management

Robotics are getting a larger role in manufacturing due to the COVID-19 pandemic.

Fewer touchpoints, improved remote monitoring and Industrial Internet of Things (IIoT) advances make it easier for robots to operate independently.

Robots also help make manufacturing future-proof, which is critical as the pandemic changes the nature of work.

CONSIDER THIS

What other ways can robots help manufacturers out during and after the COVID-19 pandemic?