The oil and gas industry is facing a skills gap and companies are integrating industrial Internet of Things cloud-based automation to mitigate this problem.

Learning Objectives

- The industrial Internet of Things is creating new methodologies to collect, process and push data from the network edge to back-end servers using cloud-based systems.

- Data from multiple devices can be correlated using real-time cloud processing and analytics to create prescriptive and actionable outcomes on the well pad, while extending traditional supervisory control and data acquisition systems with actionable intelligence and adaptive analytics.

Oil and gas insights

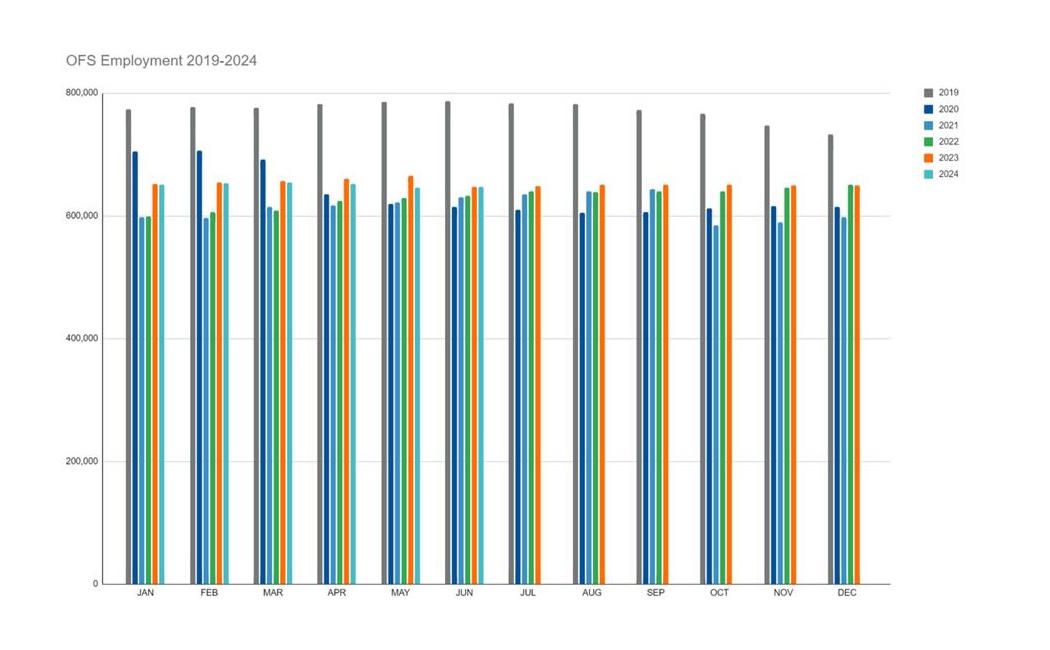

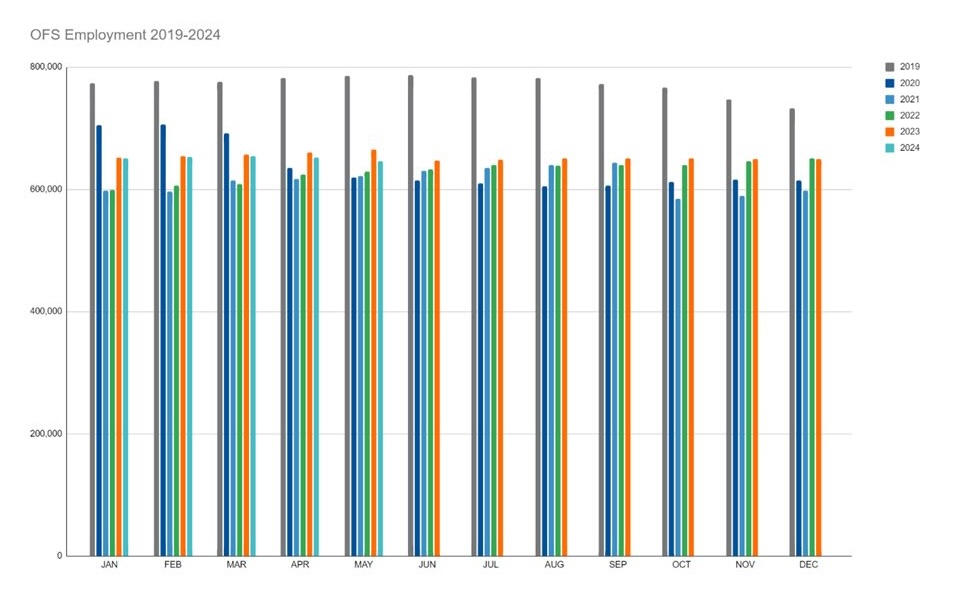

- The oil and gas industry and particularly oil field operations, is facing an imminent shortage of talented and trained workers, putting production performance and equipment reliability at risk.

- To mitigate the impact of this problem, a growing number of oil field sites are integrating IIoT cloud-based automation, using wireless data collection from edge assets and employing intelligent gateways capable of connecting data from edge assets to the cloud.

According to the report, Science & Engineering Indicators 2018, prepared by the National Science Foundation, “The demographic composition of the science and engineering workforce in the United States is changing. The baby boom portion of the S&E workforce continues to age into retirement. Mirroring U.S. population trends, the science and engineering labor force (worldwide) is aging.”

The oil and gas industry is at risk due to its dependence on oil price fluctuations. In the 1970s, thousands of baby boomers studied petroleum engineering and other energy professions when oil prices were high. However, layoffs in the 1990s discouraged an entire generation from joining the industry.

This great crew change is a phenomenon where high retirement rates and a widening employee demographic gap have created a significant skill shortage in the oil and gas industry. The pool of open skilled jobs in oil and gas is growing as employers are finding these positions more difficult to fill with younger qualified candidates.

Retiring engineers, technicians and workers take decades of experience and expertise and knowledge of oil and gas process operations with them. Much of this equipment was installed at the oil field and in processing facilities 40 to 50 years earlier. Maintaining robust and effective maintenance and upgrade of this equipment and securing its reliability, is crucial as the equipment continues to age.

Minimizing the skills gap

Oil and gas companies are implementing new ways to recruit and train young engineers, technicians and field workers in the skills needed to bridge the gap. This is a vital and proactive step forward, but it is not enough.

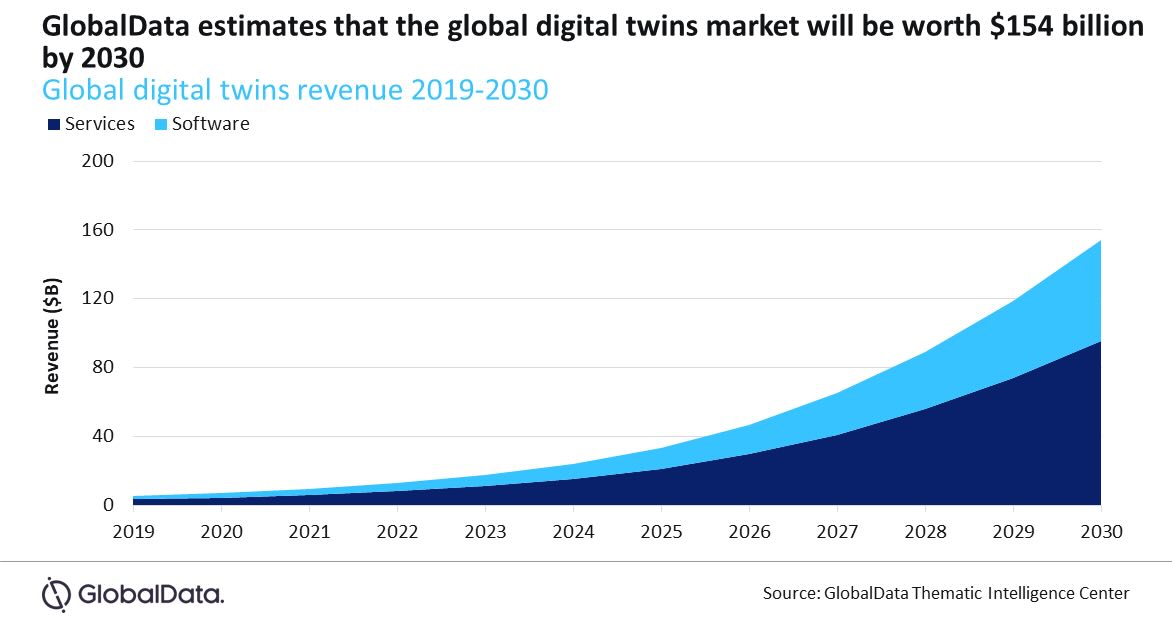

Oil and gas companies are starting to turn to automation to alleviate the skills gap problem by using industrial Internet of Things (IIoT) cloud-based automation. Wireless data collection sensors on edge processes are used to maintain, upgrade and extend longevity of their key assets in the oil field and in downstream processing facilities.

Employing specialized gateways capable of connecting data from edge assets to the cloud, they are interacting in real time to new machine learning and application services interface applications, without interrupting existing supervisory control and data acquisition (SCADA) functionality.

A broad base of recorded engineering and maintenance knowledge on these systems and processes is recorded and available for immediate condition and predictive analysis.

Contrast this with the data collected from manual condition monitoring and noncloud-based automation techniques, which is often undertaken by oil and gas maintenance and engineering personnel, where not all equipment is accessible, sometimes due to hazardous locations. An oil and gas producer also may have many wells being maintained by a small number of instumentation engineers and workers in the field.

While existing noncloud-based automation may provide some insight into issues, it is often reactive, informing operators of what went wrong after the problem has escalated to critical failure. Operators often do not have the time to inspect and study the data from wells that appear to be operating properly to discover what may go wrong. The instincts of a career oil worker is often used to identify or determine what action should be taken. As the crew change evolves, much of this experiential practical knowledge that took years to acquire will disappear, making manual and noncloud-based automation increasingly less effective.

Subsequent data analysis for system faults is only be as good as the consistency of collection protocols and continuity over time of the data collection. Infrequent condition monitoring, as well as personnel transfers or leaves, interrupt this continuity.

In view of these circumstances, cloud-based, real-time monitoring is not only an ideal and proven method of capturing data from these assets, but it also has the tangible effect of reducing oil and gas companies’ reliance on the transfer of knowledge from an experienced to a novice workforce to help compensate and minimize the workforce skills gap.

IIoT platform for oil and gas well sites

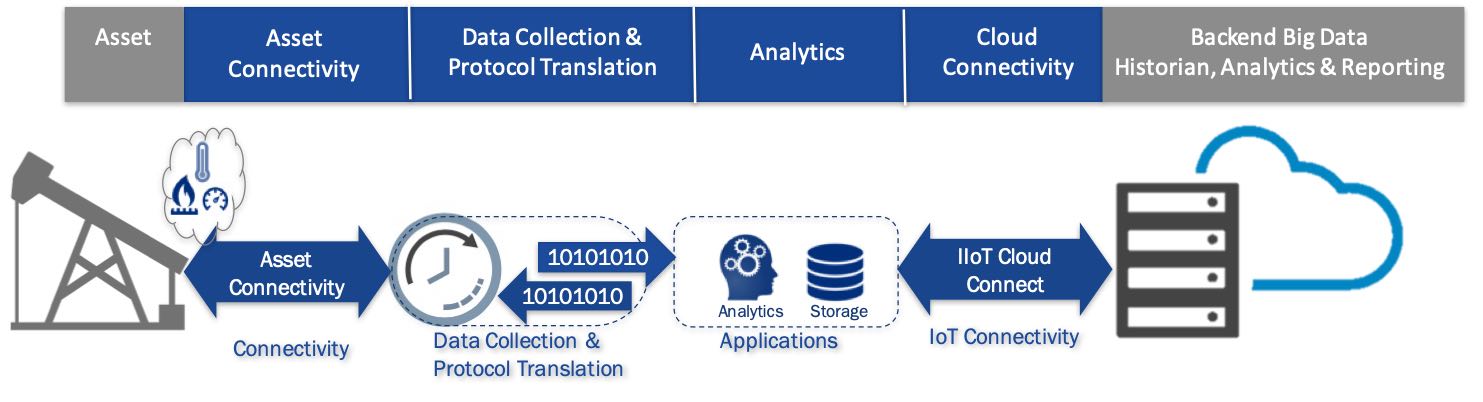

The IIoT is creating new methodologies to collect, process and push data from the network edge to back-end servers using cloud-based systems. One system that simplifies the complex landscape of the IIoT and connects valuable assets to new cloud solutions is an IIoT platform, which can provide tools that can bridge traditional 1980s control technologies to real-time IIoT edge appliances.

An IIoT platform provides actionable operational intelligence that improves decision intelligence, provides risk assessment and generates prescriptive outcomes leveraging IIoT and artificial intelligence technologies to optimize operations across the well pad.

The platform is designed to run secure, device-specific applications at the edge, similar to a smartphone enabling data from existing legacy devices, to support edge processing and analytics. Data from multiple devices can be correlated using real-time cloud processing and analytics to create prescriptive and actionable outcomes on the well pad.

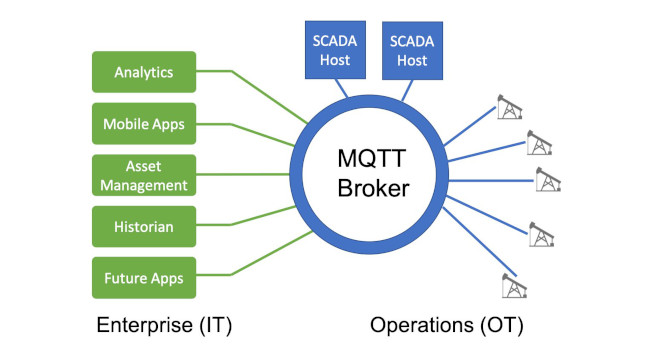

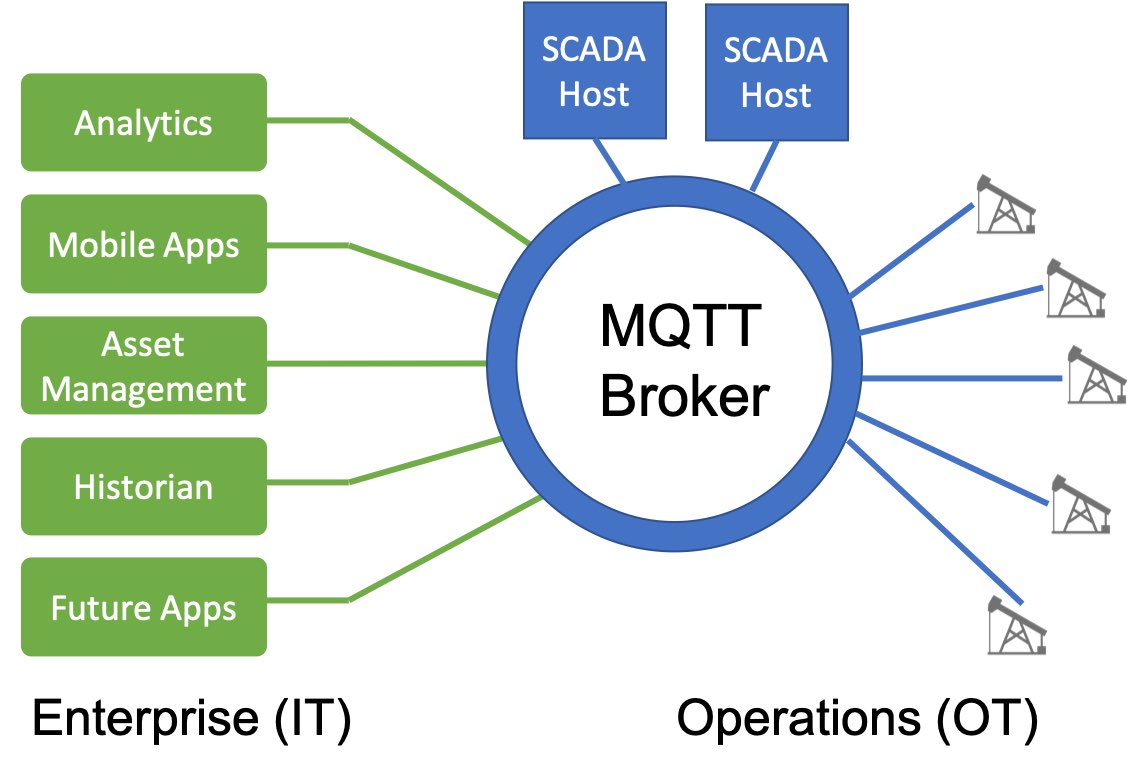

The platform scales to support private or public cloud-based visualization platforms and does not interfere with existing SCADA operations. The open, standard-based platform enables vendor agnostic data models, controls and management.

The IIoT platform uses a gateway, which provides a rich set of edge functionality, collecting data by polling critical infrastructure and industrial application sensors at the edge, assessing the system state every second.

The gateway provides secure connectivity to industrial controllers, process automation and smart grid assets in the field using legacy and modern protocols without disrupting existing legacy SCADA platforms.

An IIoT gateway provides many features designed to simplify the development of edge applications by reducing the time to create and integrate them. This enables innovative edge applications to be created and integrated to existing infrastructure and IIoT applications.

Wireless connectivity provides data collection for IIoT sensors in the oil field, working with the gateway. These help simplify connecting and managing sensors and controllers and provide a secure connection to transmit data real-time to oil and gas companies.

Using the cloud platform for oil field analytics

An IIoT cloud platform exchanges data from the edge gateway and input/output devices. It provides cloud computing capability across a set of correlated assets analyzing process flow to assess risk and provide prescriptive outcomes to issues.

The IIoT cloud platform is designed to process real-time insights and extends SCADA with actionable intelligence and adaptive analytics. It leverages low-code solution templates and lets users rapidly build digital apps and automate critical workflows. The platform creates action from data and extends analytics with personalized workflows, automated rules and alerts that solve unique business challenges. It also integrates with existing IT systems, cloud platforms and external systems from ecosystem partners.

The IIoT cloud platform uses IIoT-based automation, consisting of its edge gateway and standards-based wireless I/O connectivity, to instrument and model the entire process flow. Its cloud-based backend provides real-time processing to correlate the sensor data and create meaningful time-series data of the entire well process, including artificial lift, test separator, well-pad separator, tank storage, gas flow measurement, water disposal and custody transfer of the oil from the pad.

The time-series data can be monitored using a risk model, with actionable intelligence and adaptive analytics that include economic impact across the fleet wells. The end result is a risk-weighted list of potential problems and prescriptive measures that may remedy them.

Seeing the bigger picture

Industries engaged in oil and gas production are losing know-how and experience through the loss of seasoned engineering and other technical personnel. Poor systems in place for the acquisition of asset data and performance such as manual and noncloud-based data collection result in inadequate knowledge and learning to facilitate cost-efficient oil field performance.

Within the IIoT cloud-based, real-time data collection framework, well site process information can be collected to a big-data cloud database, which is designed to provide information for different applications that are requiring data. This means a much higher volume of data can be gathered from the well pad metrics and made available in a common format, to allow for broader usage and analytics.

An IIoT cloud platform can provide a sustainable resolution to the oil and gas industry’s skills gap.