Robots can augment and enhance the plant floor by handling the dirty, dull and dangerous tasks and work safely alongside humans.

Over at the FedEx repair facility in Collierville, Tenn., robots stock office shelves, move items around the office, and process items back to their bot colleagues in New York. Human workers help them. Industrial robots have occupied America’s workplace for more than four decades. In 2017, the Robotic Industries Association (RIA) estimated more than 250,000 robots had been installed in the United States.

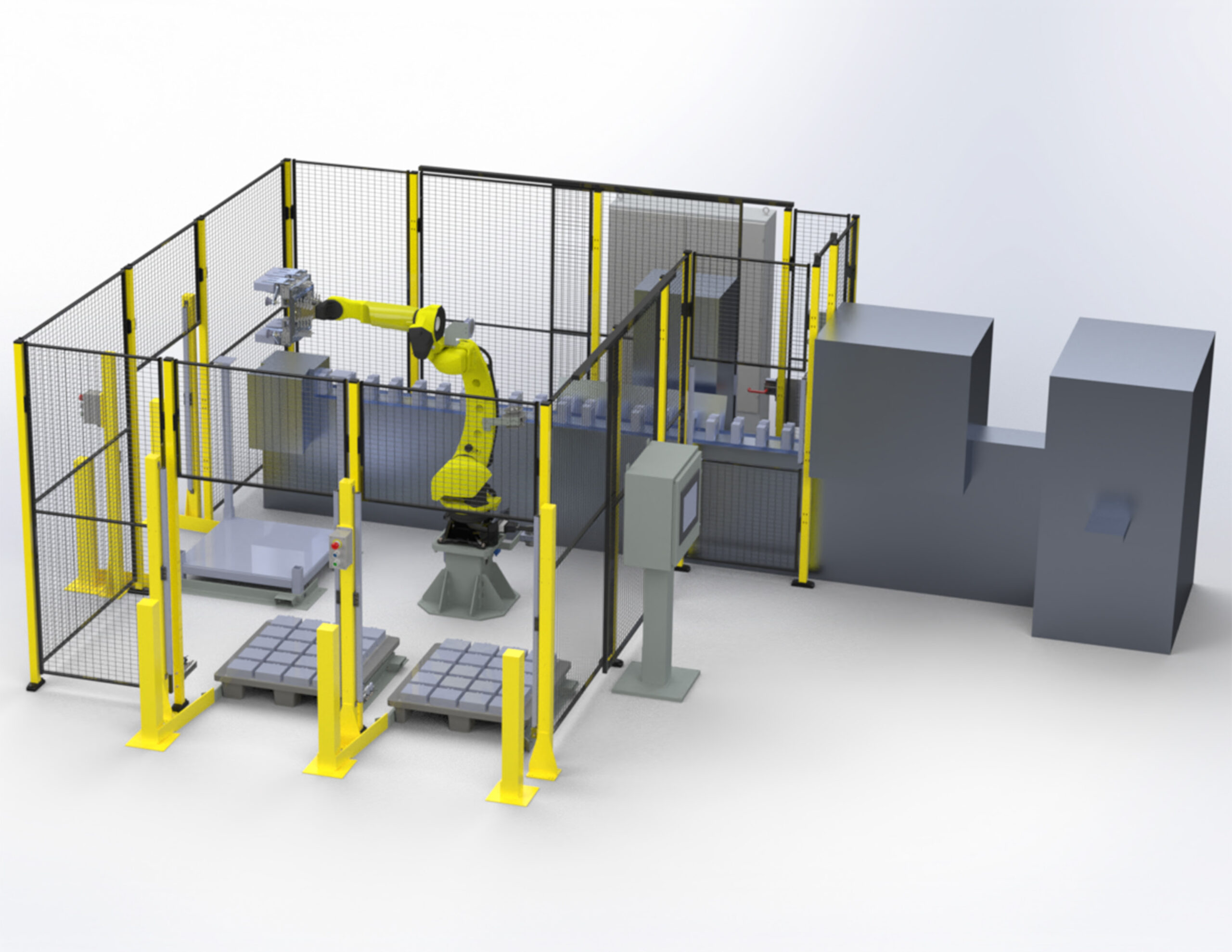

Back then, those massive, heavyweight robot builds mostly performed tasks such as welding, painting or assembly from cages or isolated enclosures. Today, a smaller, safer and cheaper version of industrial robots, called a collaborative robot, works side by side with humans to protect humans from injuries or adverse health effects, like musculoskeletal disorders and falls. Collaborative robots, or cobots, also minimize human error.

At Procter & Gamble, for instance, “Robots are integrated throughout the manufacturing process. In most cases these systems coexist with humans and other automation across the production lines. There are many tasks that people do very well, and we develop systems that leverage the best capabilities of humans, robots, and automation,” said Mark Lewandowski, the company’s Robotics Technology Network Innovation Leader and a pioneer in P&G’s use of robotics.

In a presentation at the International Collaborative Robots Workshop in 2016, Lewandowski described how P&G uses collaborative robots to automate tasks that are too complex or hazardous for humans.

Roles for robots

Collaborative robots typically replace humans with accomplishing the three Ds: dull, dirty and dangerous jobs.

Lewandoski said, “We use collaborative robots for unscrambling and loading parts into machines, case packing of finished products into cartons, stacking cartons on pallets used for shipping, doing repetitive tasks in R&D labs like pouring samples or loading test samples into testing equipment.”

At FedEx, Relay robots help mailmen accomplish tens of thousands of deliveries as well as ferry goods around warehouse floors.

“Our motto with our team members is always that we are installing the robots because we want to keep you as FedEx team members,” said Aaron Prather, senior advisor for the Technology Research and Planning group at FedEx. “We generally utilize robots for tasks that are repetitive. Our pick and place robots, for example, replace very dull induction jobs, and our autonomous tugs replace the dull and sometimes dangerous job of driving a vehicle around and around in a facility.”

In that capacity, robots produce fewer errors than humans typically do when accomplishing that same repetitive tedious work.

In other instances, collaborative robots fill jobs left vacant by human beings, as in a furniture company in Massachusetts, where employees conceded it was collaborative robots that helped them survive after their business failed to find enough humans who wanted to do the work.

Safety practices for collaborative robots

In 2017, the Occupational Safety and Health Administration (OSHA), the US National Institute for Occupational Safety and Health (NIOSH), and the RIA formed an alliance to develop research that would identify and reduce workplace hazards associated with human-robot collaboration. That same year, NIOSH launched the Center for Occupational Robotics Research to “provide scientific leadership to guide the development and use of occupational robots that enhance worker safety, health, and well-being.”

Although robots have become safer with the years, RIA still recommends companies perform robot risk assessments and execute programs on cobot safety. RIA also publishes several safety guidelines related to collaborative robot safety, which include the RIA TR R15.606 – 2016 – Collaborative Robots and the RIA TR R15.806 – 2018 – Testing Methods for Power & Force Limited Collaborative Applications.

Bob Bollinger, applied innovation leader at P&G Robotics, said, “We apply applicable standards to ensure safe worker and robot interaction.”

Robot collaboration rather than job elimination

Companies like FedEx or Procter & Gamble focus on uptraining, or upskilling, employees to collaborate with robots rather than to eliminate jobs. The most successful programs combine in-house training with online education platforms and community colleges. Those are similar to initiatives offered by P&G that “leverage internal training, external training, and on the job experience to “up-skill” workers and technical resources who interact with advanced automation and robots,” said Bollinger.

“FedEx, too,” Prather said, “is committed to investing in our team members’ education and career advancement to equip them for the jobs of the future.”

At FedEx, Prather added:

Team members who volunteer to become Robot Team Leaders will either attend vendor training sessions or internal FedEx classes that teach them the basics on robot operations and safety. We are continually re-evaluating our training resources to ensure that our existing workforce is prepared for these new roles as we increasingly incorporate robotics and automation into our operations.

Amazon brands its uptraining programs “kind of like grad school” and calls them its “free university.”

Other tips for successfully integrating robots and humans include leaving the purposeful tasks to humans, while letting robots perform the more mundane or hazardous responsibilities. Attorneys from Lexis Practice Advisor also recommend managers incorporate policies and procedures to help humans and robots harmoniously collaborate.

Robots will not replace all our jobs. Studies note that jobs that involve social intelligence, dexterity or creativity are best suited for humans, as are those jobs that have a high level of unpredictability and operate in cramped quarters. Naturally, humans are the ones who supervise, train and fix our machine colleagues. Otherwise, it’s a symbiotic relationship, where humans and robots hand materials and parts to one another and labor alongside accomplishing their tasks.

This article originally appeared on the Robotic Industries Association website. The Robotic Industries Association (RIA) is a part of the Association for Advancing Automation (A3), a CFE Media content partner. Edited by Chris Vavra, associate editor, Control Engineering, CFE Media, [email protected].