Taking control in an uncontrolled time: Leaders share lessons from the industrial automation, controls, and manufacturing industries during the COVID-19 pandemic.

The COVID-19 impact continues to be felt around the world and has created unforeseen hurdles with regards to its people, economy, industry, and engineering. With varying messages and new information being uncovered daily, it can begin to feel as if we are losing control. Experts in controls, automation, and manufacturing from around the country offered some promising advice.

System integration

As CEO of Control System Integrators Association (CSIA) Jose Rivera explains, “It’s clear, every business will be impacted by this. We will also see areas of strength and growth emerge as well, but in time. The good thing about an industry packed full of engineers, you’ve got a lot of folks that were prepared as best they could be and had systems in place to battle through this. Whether that is remote work setup, company e-meetings, applying virtual control engineering principles, etc. Of course, there will be lots of adapting on the fly, but engineers are good at that too.”

Rivera shared several stories of how CSIA members are changing their remote strategies.

“We have some companies that are not just doing remote engineering work like testing and virtual factory acceptance tests (FATs), they’re also continuing to focus on that office culture and team bonding piece that is so important, as well. One company even went as far as sending delivery birthday cake to an employee while all colleagues call in via Zoom to sing ‘Happy Birthday.’ Don’t get me wrong, we are in a tough time, and it will not be easy, but we will get there if we continue to work together.”

3D printing

There are other positive stories popping up throughout the country. Robert Fell is president at Iris Custom Solutions, a company focused on providing custom automation and system integration. He and his team immediately sprang into action amid the crisis. They had 3D printing technology available and decided the best use for it would be to create shields for the overwhelmed medical supply industry.

“Our goal is to get 1,500 new shields to New York as quickly as possible. We’re sending them in smaller batch sizes of around 400 per week. We will continue to try and help where we can. We’ve even ordered more 3D printers.”

Fell and his engineering team are doing this while running day-to-day business. Engineering skill sets are being applied in new ways, especially now.

Data sciences, robotics

There are even groups applying control theory principles to healthcare system capacity problems and sharing their findings on LinkedIn. Greg Stewart, a data science expert at Ecoation, a company that offers an automated greenhouse management platform turned expertise to coronavirus by looking at policy design for stable population recovery. The work applies control principles to hospital capacity problems the pandemic has created. Ecoation and others are using engineering skillsets to help encourage collaboration among control communities to address pandemic-related global challenges.

Companies are addressing internal situations as well.

Charles Lowrey, controls engineering manager at Calvary Robotics, noticed areas challenging and surprising control engineering managers.

“Anytime your primary market is impacted by external forces beyond your control, it is a test of an organizations preparedness and adaptability. Webcams and teleconferencing are becoming essential to keeping teams focused on the same goals. Managers and team leads are being challenged to find new ways to provide direction and mentor without face-to-face meetings. I think people also are surprised at the volume of work they’re able to accomplish at home relative to the office,” Lowrey said. He believes the control engineering skillset will continue to hold major value, in person or digitally. There are many ways skillsets can transfer to new industries and situations, Lowrey noted.

Automation benefits

Gary Miller, president of the Miller Resource Group, agreed with Lowrey.

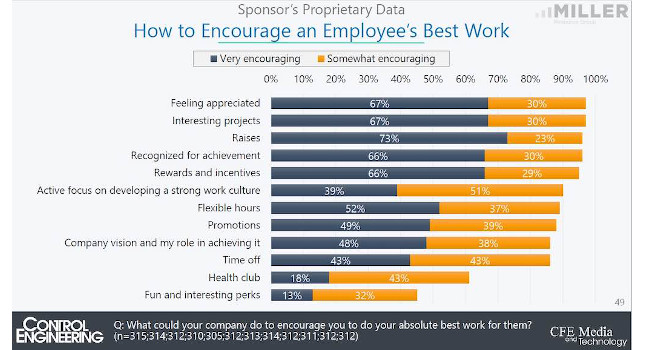

“I’ve always viewed the control center as just that, the center of any automation system. Control engineers can view themselves the same way, at the center of all engineering disciplines. Because they are part of a larger engineering community, the value of digital networking via sources like LinkedIn can become a major resource in times like this. It’s a place for them to increase their learning, allow them to contribute, and hence, increase their value.”

Value creation and business development opportunities continue to develop.

EN Automation’s director of business development, Garett Williams, discussed preparedness and outlook for engineering, consulting, and environmental services.

“We were as ready as you can be for something like this. Fortunately, we had remote strategies in place already which helped us keep things moving. We are even seeing an uptick in business development activities at this time, especially when you factor in various things like travel time being eliminated. We’re keeping virtual messaging high, but doing it in a highly targeted manner using video campaigns and other various apps to create a more custom, unique message. I guess you could say while we’re still adhering to the new norms of society and keeping distant physically, we’re also maintaining the important social aspect of our job,” Williams said.

The EN Automation team has been working with current and new partners to ensure automation systems are performing optimally now and into the future, with new needs emerging frequently.

“Through some of the conversations we are having, it’s clear that future partnerships are being formed right now with this pandemic shining a light on certain areas that companies are seeing areas of need or systems that need to be updated”, said Williams.

Ryan Prickette, an industry sales leader at Rockwell Automation, is noticing some positive trends as well. “There is more flexibility and understanding of ways we can serve customers virtually or alternatively. There will be several new opportunities created in terms of helping customers to be better prepared to handle future situations like this,” Prickette said.

From various perspectives, “wins” are happening within the automation industry’s talented network. People are attempting to apply tighter controls over what they can influence, applying engineering and business development principles, and adapting on the fly, lessons that many can consider and benefit from.

Jeff Briggs is industrial automation recruiting specialist, Miller Resource Group. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

Register to see the Control Engineering Career and Salary Report, 2020.

MORE ANSWERS

KEYWORDS: Engineering skills, COVID-19

COVID-19 is affecting people, economy, industry, and engineering.

Remote capabilities and productivity are increasing.

Engineering talents are being applied and appreciated in new ways.

CONSIDER THIS

What engineering skills are you applying to the COVID-19 responses?