Manufacturers and vendors are collaborating to find better solutions to gain better insights from the data they’re collecting so better decisions are made.

Asset management insights

- Some vendors are collaborating with manufacturers to find solutions to many different challenges.

- Improving the data stream is important, but so is improving the analytics and tools used before and after so better and more informed decisions can be made.

Hannover Messe was much livelier Tuesday as more people came in after the Orthodox Easter holiday, and the activity reflected that overall. Many customers are looking for solutions for problems. In many booths, however, they are seeing how companies are working together with different vendors to make solutions that are better for everyone involved.

That might seem like a strange concept given how companies are often competing with one another. At the Amazon Web Services (AWS) booth, collaboration is the point.

“Here are the AWS booth, we are highlighting 30 different vendors sending all their data, and we’re feeding it into one center to help make better products,” said an Amazon spokesperson. “When it comes to data gathering and putting it all together, not a lot of manufacturers want to do this themselves.”

More to the point, they said they want to bring operational technology (OT) and information technology (IT) together.

Many of the services they provide are designed to help OT engineers and educate them in the tasks that, normally, should not require IT. Educating the OT engineer helps them understand what to look for and make better decisions based on the data they have.

“We’re interested in helping our customers get more value from their data,” the spokesperson said. “Companies often start out with a use case that’s successful and then they move on to the next thing and scale it up, but scaling is tough if the companies don’t have the proper context and understanding, which is what we try and provide for them.”

Creating a streamlined approach, tying the digital thread

Microsoft’s booth emphasized cloud and edge computing solutions throughout its booth. Vendors there were mostly focused on automating processes wherever possible and, when human intervention was needed, processes that didn’t require a lot of thought or action.

Tulip Interfaces’ focus was about augmenting frontline workers with connected applications and using apps to give engineers real-time information and alerting them to challenges or issues as they come up.

Lee Lewis, an enterprise account executive for Tulip, said, “We want the engineer to tweak it for their own preference. Very drag-and-drop. We made it so you can build your own app and tweak as needed. We want to put people in the best place to resolve the solution.”

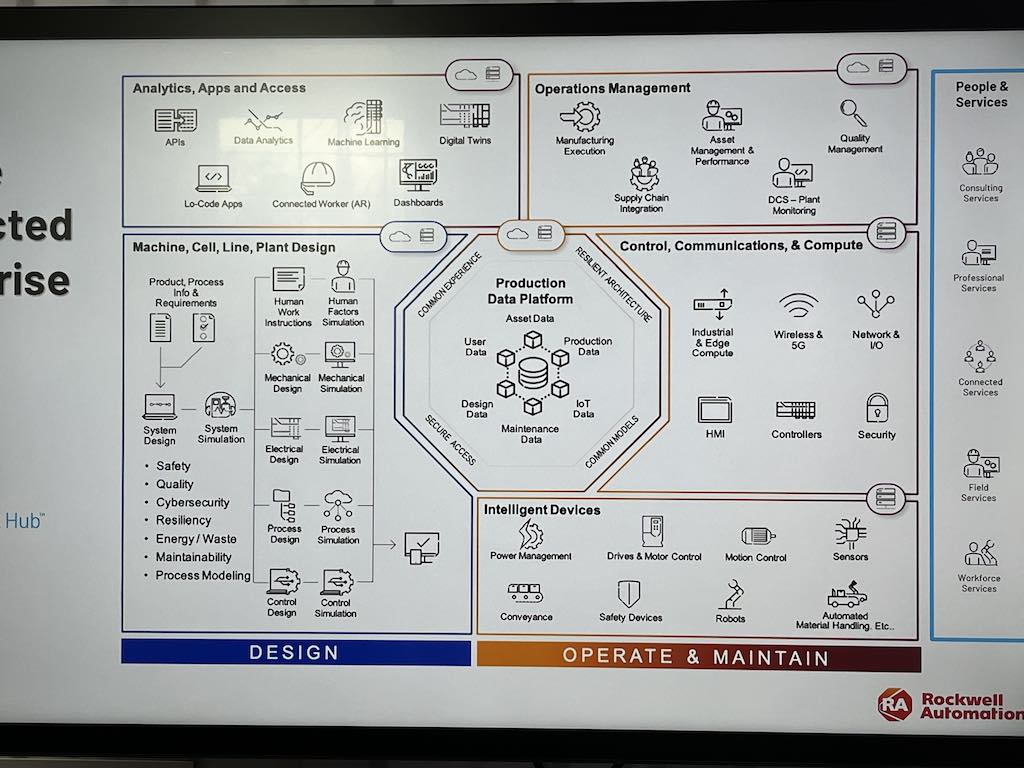

Rockwell Automation is doing the same thing by using its partner program and those relationships to get the most value for its customers.

Corey Jurek, a technology consultant for Rockwell Automation, described a pick-and-place robot with the robot arm provided by Comau. Rather than have the robot arm and other pieces from other manufacturers causing a potential headache for users, Jurek said they simplified the process.

“What we’ve done is taken the robot controller aside, and we’ve installed our own encoder instead.”

Taking control of the base concept goes beyond the robot arm, though. They want to be able to provide users with all the information they need from the bottom on up and give engineers the best possible view of their data.

“We’re trying to be agnostic,” said Nina Tebbe, head of software sales for Central Europe for Rockwell Automation. “Regardless of whether it’s greenfield or brownfield, we want to tie the digital thread together. We want to take what’s there and weave it together.”

For a lot of these companies involved in collaboration and cooperation, that is what it comes down to: Finding a common point where all the data can reside, and the user can make their own decisions with the tools they have.

Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].