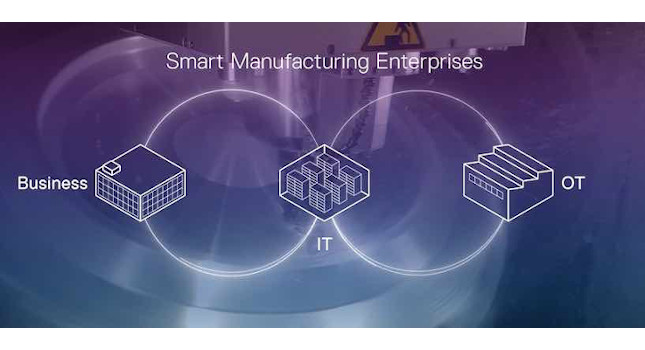

Siemens is launching a gateway based on the Intel Quark chip family onto the market which links cloud, in-company IT and production. The Simatic IOT2000 is designed for industrial IT solutions that acquire, process and transfer data directly in the production environment.

Siemens is launching a gateway based on the Intel Quark chip family onto the market which links cloud, in-company IT and production. The Simatic IOT2000 is designed for industrial IT solutions that acquire, process and transfer data directly in the production environment. For example, it can be used to connect the production to a cloud-based analysis of machine and production data.

This gateway can also be retrofitted in existing plants, where it then harmonizes communication between different data sources, analyzes the data, and passes it on for evaluation in, for example, a cloud. The cloud could be MindSphere, the Siemens Cloud for Industry, or any other cloud preferred by the user. The Simatic IOT2000 complements the MindConnect Nano cloud gateway from Siemens. This is already on the market, and is specifically designed for MindSphere and SAP Hana.

The hardware of the new Simatic IOT2000 gateway is based on rugged, reliable and long-lasting industrial technology and has a compact design. The device is suitable for mounting on a standard rail, and is equipped with a power-saving Intel Quark processor x1020 (+Secure Boot), 1 gigabyte RAM, battery-backed RTC (real time clock) and a large number of interfaces, including 2 x Ethernet and 2 x RS 232/485. Simatic IOT2000 can be easily expanded for tailor-made solutions with Arduino Shields and miniPCIe Cards. It also supports Yocto Linux and many other options for programming in high-level languages.

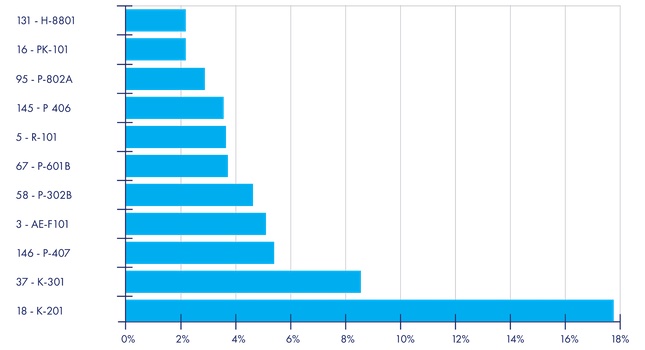

The Simatic IOT2000 is typically used for preventive machine maintenance to minimize expensive production downtimes. Relevant indicators are also evaluated and impending signs of wear are detected at an early stage. The Simatic IOT2000 records and stores the relevant data, transfers it to a cloud-based analysis tool, and then transfers the evaluated data from the cloud to the production maintenance system. This continuous data exchange closes the control loop for optimizing the maintenance intervals in a production plant.

– Edited from a Siemens press release by CFE Media.