One of the problems with industrial maintenance these days is that it's, well, maintenance. Maintenance by definition means keeping things the way they are (or in original condition), and that won't hack it any more.

One of the problems with industrial maintenance these days is that it’s, well, maintenance. Maintenance by definition means keeping things the way they are (or in original condition), and that won’t hack it any more.

This was brought home for me as I listened to the presentations at DuPont’s “Asset Productivity Conference” last month. The company brought together some 200 managers from around the world to discuss and learn about improving asset productivity. It was a fascinating and exhilarating meeting that explored how asset productivity — the productive use of facilities and equipment — is key to shareholder return and how that return can be increased.

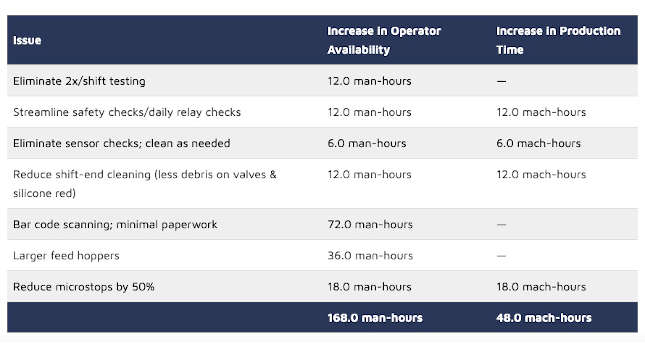

The program at DuPont moves beyond maintenance excellence to production capability. It involves the efforts of operating, engineering, and other personnel in addition to maintenance. The goal is to tap into the “hidden plant,” as DuPont calls it, by reducing outages and defects of all kinds and ensuring maximum output from available facilities.

DuPont is right on with its new emphasis. More companies, I believe, need to recognize the important relationship between their facilities and their profitability. And plant engineers have a responsibility to point the way.

Simply pushing for better maintenance falls short of the real goal, a higher level of asset effectiveness. Of course, topnotch maintenance is right up there near the top of the list of priorities. But maintenance alone isn’t enough. Maintenance, remember, is a status quo kind of thing. And what’s needed is a concerted effort to improve, to go beyond good maintenance.

What’s needed is stewardship. Stewardship is more than just maintaining. It includes an obligation for growth and improvement. A steward not only cares for the assets he is charged with, he also seeks a return on those assets.

Now, I’m not proposing that we replace the maintenance department with the stewardship department. That name just doesn’t seem to have the right ring to it. But in all seriousness, it is time to expand beyond the limitations of maintaining. In today’s world, not gaining is tantamount to losing. Because, if you’re not moving ahead faster than your competitors, you’re standing still.

DuPont’s initiative rightly recognizes the effect of asset productivity on profit and the opportunities for improvement. And while they don’t call it stewardship, that’s what I would say it’s all about.