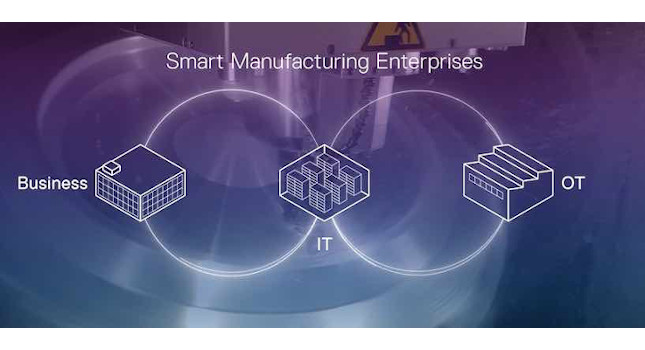

With adoption of industrial edge computing, there are several ways to support information technology/operational technology (IT/OT) convergence.

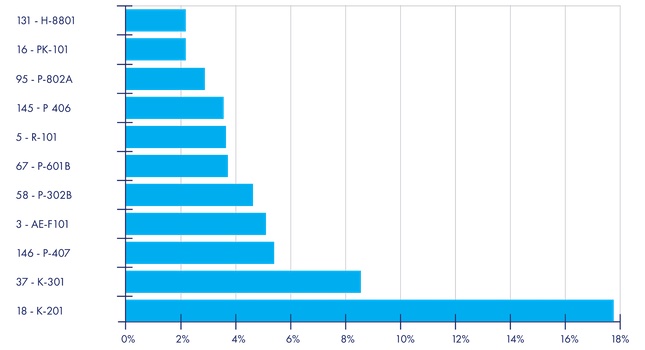

A large chemical manufacturing plant employs a heterogeneous mix of diverse assets. The asset diversity includes functional differences – such as heat exchangers, distillation columns and centrifuges – as well as asset age (a range 5 to 25+ years of age) and varying levels of modernization.

This week, customer demand is high, and the chemical plant is operating at capacity to fulfill orders and meet delivery commitments. On Tuesday, three hours into production, the reboiler on the distillation column failed, bringing the entire production process to a halt.

It took eight hours to recover from this unplanned downtime event and restart production. After that, it took another two hours to recalibrate the plant’s output to the required quality levels. The costs to the plant and the business increase quickly: estimated at US $260K per hour. In other words, those 10 hours of lost production time incurred $2.6 million in losses.

The big question

Could this unplanned downtime event have been prevented?

Although hypothetical, this scenario is based on real-world events. It showcases the critical – and vulnerable — nature of assets and production processes in chemical manufacturing. No manufacturer – in automotive, mining, pulp and paper, oil and gas and beyond – is exempt. Unplanned downtime costs manufacturers an estimated $50 billion per year. A solution to proactively mitigate these industrial losses is vital.

Across manufacturing, edge computing and its many use cases hold great promise to mitigating a multitude of production vulnerabilities, including unplanned downtime. Industrial edge computing can enable more flexibility, increase cost-effectiveness and boost global competitiveness. Early results using edge and Industrial Internet of Things (IIoT) as enablers of Industry 4.0 show impressive results and hold potential for the future.

The challenge to achieving an effective industrial edge capability lies in the successful convergence of informational technology (IT) and operational technology (OT), a concept that is easier said than done. These two functional areas are grappling with the heterogeneous environments that are a reality in manufacturing. Industrial environments often employ multiple technologies from multiple vendors and use a legacy core that may be 5 to 25 years old. It is imperative to efficiently modernize and transform storage and computation to realize positive outcomes from edge computing. (NOTE: A high level understanding of edge computing outcomes is covered here).

As IT professionals and data scientists explore industrial edge, it is crucial to understand OT perspectives before deploying edge-based solutions because people play as important of a role as the technology itself.

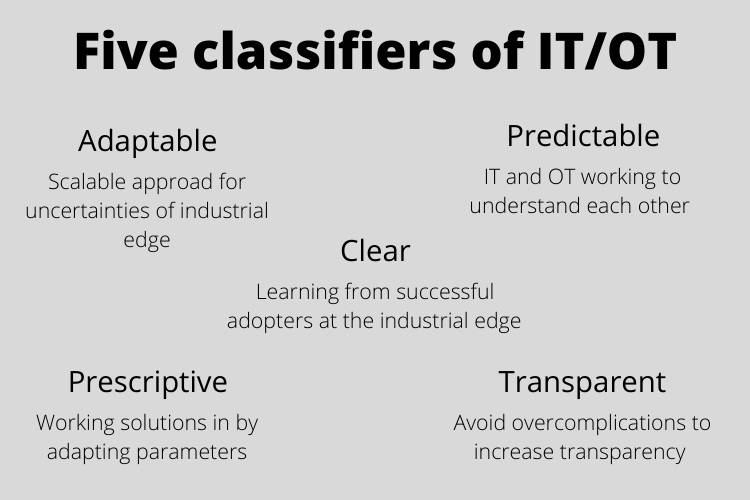

Five classifiers to IT/OT convergence

There are five classifiers for harnessing the power of industrial edge computing by bridging the IT-OT gap and expediting IT/OT convergence, specifically for IT professionals and data scientists. Understanding these classifiers and exploring the different perspectives will chart better collaboration – and thus better outcomes – at the edge. This collaboration can include edge strategy, the data fabric for artificial intelligence/machine learning (AI/ML), infrastructure modernization, transformation of people, process and technologies, governance, data security and management of deployed hardware and software solutions. In essence, these are all the factors needed to set up a successful edge compute platform.

1. Edge-based computing platforms must be adaptable to uncertainties.

IT perspective. When embarking on a modernization or transformational project related to Industry 4.0, IT professionals and data scientists tend to leverage existing data, infrastructure and available information as empirical input. Technology requirements are based on a fixed and known set of rules and relationships to predict outcomes with high probability (90+%).

OT perspective. By contrast, the industrial edge is governed by OT professionals and their real-world production environment. Diverse OT professionals use different rules, relationships and weightings based on data that may encompass a specific process or an asset. Thus, OT’s input may not serve to optimally design and deploy edge computing for an entire factory.

The solution. To bridge this gap, employ a scalable-based approach that is adaptable to the uncertainties of the industrial edge. For example, AI/ML models should encompass situations where there could be less data, more data, new data, missing data, protected data, manipulated data, dark data and synthetic data. This data could vary in degree of quality and quantity based on a real-time situation and may or may not conform to a given set of optimal rules that were pre-defined based on past classifications.

2. Recommendations must be easily understood by diverse personae.

IT perspective. Inherently, IT professionals and data scientists do not speak the language of OT professionals. Therefore, a common, clear, collaborative communication mechanism must be created to ensure any design and deployment of edge computing solutions are based on consensus and done with clarity.

OT perspective. Data and information provided by the edge compute platform must be “trustworthy” and “timely” so that it can be used to take actions that advance production. Actions can pertain to material flow, asset management, people management, process control, product quality and productivity. OT’s two primary uses of data are 1) to monitor current processes and address out-of-spec incidents and occurrences and 2} To evaluate outcomes that guide investment in continuous improvement.

The solution. It is mission critical to understand how people at the industrial edge interact with existing OT and enterprise IT systems for the continuous improvement and on-going optimization of processes and production.

3. Heuristic knowledge is essential for accuracy, simplicity and predictability.

IT perspective. Three information sources help predict the future status of a “thing”: current data, historical data within the operational system and heuristic or experiential knowledge embodied within the minds of OT professionals. While IT professionals and data scientists are often familiar with patterns around data-based sources, it’s likely they will not be familiar with OT’s capabilities.

OT perspective. OT professionals often possess deep knowledge and expertise based on rich, real-world experiences. This is known as heuristic knowledge. When that knowledge is shared with data scientists, it helps to identify simpler and highly effective algorithms for predicting the future of a thing. Similarly, when shared with IT professionals, heuristic knowledge can help deploy cost effective, resilient and scalable infrastructure to meet the needs of edge computing.

The solution. When designing and deploying edge computing solutions, experiential knowledge within the minds of OT professionals must be integrated into IT evaluations to enable successful edge deployments.

4. Prescriptive recommendations are an expected outcome at the edge.

IT perspective. Edge platforms and their use cases employ artificial intelligence and machine learning (AI/ML) to help enable “prescriptive” solutions. These solutions address risk or uncertainty in the situation at hand. IT professionals and data scientists may view prescriptive recommendations as “optimal.” However, they may not be viewed that same way by OT professionals.

OT perspective. OT professionals consider execution of prescriptive recommendations after incorporating additional criteria such as resource availability, trustworthiness of recommendations, time to execute, situational complexity, sensitivity and specificity. Thus, while prescriptive recommendations are an edge compute requirement, they will be tempered with other variables based on the operating environment.

The solution. When working on the data fabric at the industrial edge to prescribe recommendations, both IT professionals and data scientists should consider: a) The difference between risk and uncertainty when applying AI/ML models; and b) those prescriptive recommendations will not be optimal until additional parameters are factored into them.

5. At the industrial edge, transparency drives increased productivity.

IT perspective. Using data plane and control plane logic within an edge compute platform requires a degree of transparency to establish OT’s trust and adoption. AI/ML algorithms demand mathematical sophistication to achieve accuracy. In the process of achieving this accuracy, there will be a point of diminishing returns, where complexity growth will outweigh any expected benefits. To build consensus, this sophistication should be explainable so that it can be readily understood by OT.

OT perspective. Given the advanced, busy environments of real-world industrial operations, OT professionals are visually driven. By incorporating transparency at the edge, IT professionals and data scientists can choose to avoid complex and opaque stochastic models with less diminishing returns and instead adopt simpler use cases with better value propositions at the edge.

The solution. IT professionals should consider each use case and weigh the accuracy “pay-off” achieved for increased mathematical complexity. This way, overcomplications can be avoided or minimized. As a result, transparency — a key component for OT trust and edge user experiences — can be realized. Additionally, transparency enables IT and OT professionals to make appropriate and on-going adjustments to rules governing data ingestion and the inferencing that governs command and control.

Next steps

At the chemical manufacturing plant, the unplanned downtime event could have been mitigated by using industrial edge computing’s predictive maintenance use case to prevent impending failure at the lowest possible cost to repair.

Manufacturing has much to gain by leveraging the industrial edge. However, preparing for an effective edge deployment requires strategic intention to share perspectives and collaborate across IT and OT. Using the five classifiers outlined for IT professionals and data scientists should help guide that collaboration and support successful implementation at the edge.