Automotive robots bring many benefits to automotive manufacturers and increase companies' competitiveness on a global scale.

The automotive industry has long been a trailblazer in robotic technology. The first ever industrial robot, the Unimate, was installed in a General Motors factory in 1959. Since then, the automotive industry has been the biggest buyer of robotic automation equipment.

After several decades of increasing adoption of industrial robots, the number and types of robotic applications have expanded greatly. Today, automotive robots offer many benefits to automotive manufacturers in several different ways.

Modern automotive robots represent some of the most advanced robotic technology in existence. One of their most distinct and advanced features is their high degree of connectivity. Automotive robots today collect a vast amount of production data that can be sorted and analyzed for ongoing optimizations and minimal downtime.

Further, automotive robots are flexible and versatile. They can quickly be reprogrammed and repurposed when lines shift or when newer robots are purchased. They can also handle multiple different parts without reprogramming, leveraging a suite of intelligent sensors.

Five automotive robot applications

Automotive robots are used in many different ways, but there are 5 most common applications today:

- Robotic welding: every vehicle requires a high number of welds. Robots are capable of performing all of this welding, and the savings from uptime and consistency are enormous.

- Robotic assembly: for things such as windshield installation or wheel mounting, robots provide significantly increased throughput for assembly applications.

- Robotic painting: a vehicle’s paint needs to be evenly applied across a large area. The accuracy and consistency of automotive robots is a major driver of efficiency for painting applications.

- Robotic material removal: for cutting and trimming of plastics, die castings or polishing molds, the repeatability of robots is a significant advantage for improving quality in material removal.

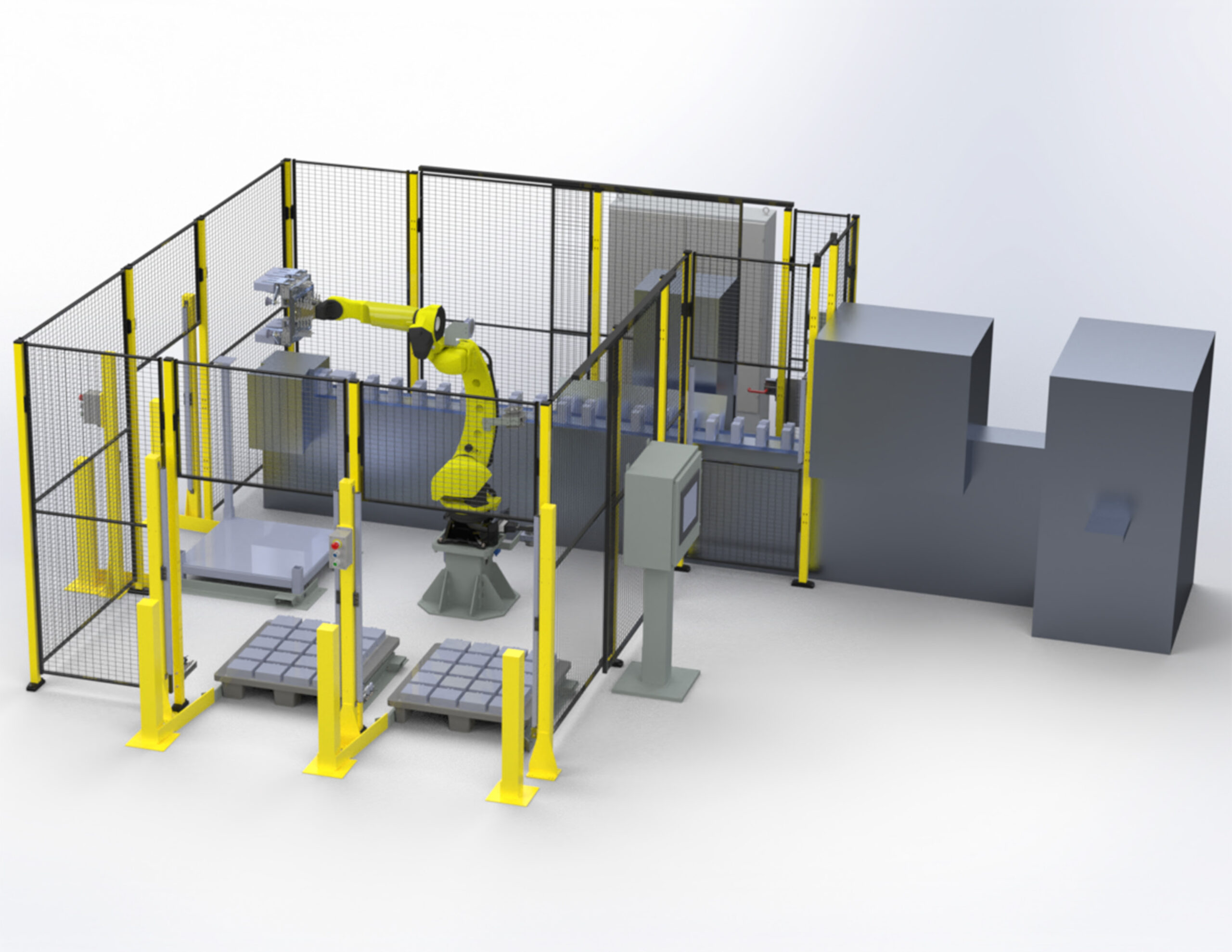

- Robotic machine tending: for loading and unloading CNC machines, automotive robots feature high levels of uptime for greater efficiency and improved throughput.

Automotive robots bring many benefits to automotive manufacturers. They also increase competitiveness on a global scale and are continuously improving productivity.

This article originally appeared on the Robotics Online Blog. Robotic Industries Association (RIA) is a part of the Association for Advancing Automation (A3), a CFE Media content partner. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].