Collaborative robots help local manufacturers meet the customer's demand for immediate products and can help control long-term costs.

Companies are going local by using collaborative robots for manufacturing. Many consumers believe that locally-manufactured products are made better, improve local economies, and are friendlier to the environment. Thanks to collaborative robots, manufacturers can potentially align their products with these ideals.

Consumers want to receive their products fast, so much so they’ll often pay subscription fees or expedited shipping charges to receive their goods in days or sometimes even hours. Offshore manufacturing can result in shipping delays that force buyers to seek out the competition. Warehousing a large amount of products often results in more waste and less available capital.

Traceability has also become more important in today’s global economy. Counterfeit or tainted products can be a risk to consumer health and a business’s reputation. Moving those products closer to home can help to eliminate these risks. Having production facilities closer to home also can result in stronger working relationships as teams meet together in person more frequently.

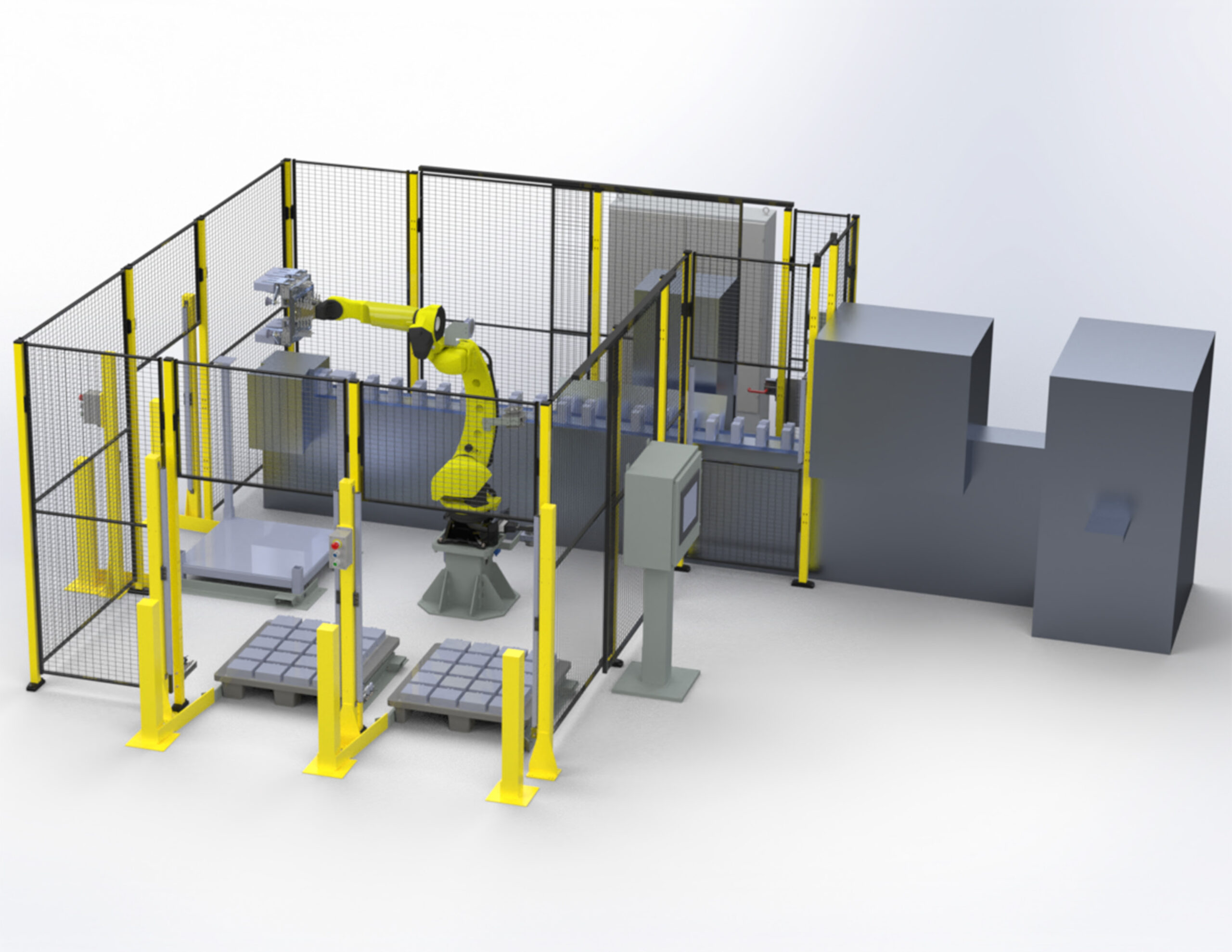

Three immediate impacts of using collaborative robots

Businesses understandably would appreciate some of these benefits of manufacturing locally. But how could collaborative robots help? There’s no denying that the initial costs of automation will require a substantial investment. But, there are many key areas where using collaborative robots for manufacturing pays off. Three in particular are highlighted.

1. Environmental sustainability. There’s a good chance that your customers are concerned about the environment. Many consumers will even choose a brand based on their green initiatives. Buyers often fear that products manufactured in countries with little regulation will wreck the atmosphere, not to mention the environmental impact of shipping. Using local automation can help companies go green.

2. Product quality. Thanks to the growing labor shortage, manufacturers often struggle to find skilled workers. You’ve probably seen positions go unfilled in your business. Collaborative robots can help less-skilled employees perform complex tasks. They can also perform inspections with higher accuracy. And robotic finishing processes ensure tight control on the end product’s appearance.

3. Financial stability. Having your products manufactured in a foreign country adds another layer of complexity when it comes to finances. What if new tariffs are imposed? When using collaborative robots in manufacturing, many costs can be fixed. The expense can be planned in advance as well as their production capabilities.

This article originally appeared on the Robotics Online Blog. Robotic Industries Association (RIA) is a part of the Association for Advancing Automation (A3), a CFE Media content partner.