Smart data and your team’s intuitive grasp can shape the future.

Field production, transportation networks, and processing facilities generate large amounts of data across the oil & gas industry. This data, on a day-to-day basis, gives operators key insights needed to maximize production.

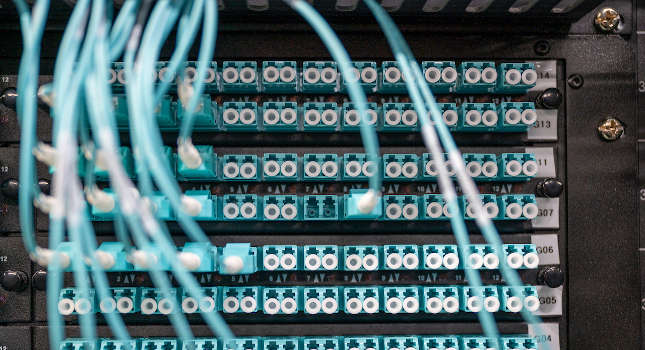

Industrial Internet of Things (IIoT) technology solutions use this same valuable data stream-even from remote production sites-and combine and organize the data within a cloud-based system. Advanced functionality, like machine learning and data analytics, can identify issues, trends, and patterns. You’ll hear this described as "predictive analytics."

Simply put, using historical and real-time operational data, the technology makes predictions about future events. Supplying insights unique to your equipment and operations, it can warn about approaching critical issues before a failure happens, and pinpoint root causes of a problem. Money is saved by avoiding unexpected downtime and related production loss, while simplifying diagnostic and repair processes.

Production, maintenance, and engineering teams know more about a facility than anyone else, including any mechanical quirks or unique equipment parameters. IIoT technology harnesses this in-depth knowledge, combined with machine-learning capabilities, to create the core rules that refine raw data into meaningful insights.

Getting smart

Data doesn’t start out "smart." At first, it’s just a long stream of numbers. Interpreting it requires identifying, gathering, and analyzing relevant information, such as regular equipment maintenance schedules, repair history, manufacturer’s specifications, and expected equipment life. IIoT software can learn the equipment’s safe operating parameters, and inform, through automatically triggered alerts, when it is operating outside its safe range.

Moreover, a team’s unique understanding of equipment issues and how to resolve them can be recorded and integrated into the rules. Take, for example, a compressor with a history of breaking down. The team knows the problem and the solution. The steps they take, from issue identification to its resolution, can be fed into the IIoT system to accelerate the diagnosis and repair process.

The right combination of human insight and machine learning can transform raw data into a digital analytics model, or digital twin, for each connected piece of equipment. This digital model can provide real-time status information and historical operating traits, as well as compare equipment performance against other similar or peak-performing equipment at a facility. The digital model also can optimize operational efficiency a number of ways.

It can prioritize repair work based on the urgency of the equipment issues in the queue. It can introduce prescriptive repair procedures to streamline maintenance. And it can determine precisely the replacement parts and expertise required to resolve upcoming problems, improving your inventory management and work scheduling.

Monitoring equipment operating conditions, such as temperature, pressure, and power, provides an early warning of critical issues that could lead to equipment failure or operating issues. The solution also provides actionable recommendations to prevent or correct problems.

Of course, just because equipment briefly operates under conditions that could lead to failure doesn’t mean it will fail. However, by considering the unique operating states of all connected equipment, operators can fine-tune equipment service schedules based on actual conditions.

Uniform populations

To illustrate the use case for this level of tailored maintenance, take a uniform population of compressors with the same manufacturer-recommended maintenance schedules. Although they’re all the same make and model, operating conditions vary from one compressor to the next, causing oil lubrication properties to break down at the different speeds.

If some compressors are exposed to operational or environmental factors that accelerate this breakdown rate, those assets will need oil changes more frequently than others. Identifying what pieces of equipment are thereby impacted isn’t feasible for most people. Machine learning, on the other hand, can sift through an enormous quantity of information to pinpoint the patterns that lead to premature breakdown.

In the oil & gas industry, using analytics to identify trends and patterns in raw data, IIoT software can monitor operating conditions across an entire portfolio of connected equipment. This can include field equipment, pipelines, trucks, and refinery equipment. In a failure situation, it also shares data-driven insights into the likely root cause so technicians fix the issue faster.

IIoT solutions continue to learn, absorbing the diagnostic steps taken, the issue detected, the solution found, and the result. The recommendations it provides evolve and improve over time, optimizing and adapting through machine learning.

An IIoT technology solution enables real-time monitoring through dashboard visualizations that provide insights into equipment performance, as well as leading indicators of potential future issues. Dashboards can be integrated with existing data management and control systems and, when connected to the cloud, highly accessible. What’s more, a dashboard allows comparison of insights taken from multiple operations-be it production sites, pipelines or refineries-to optimize equipment performance, efficiency, and safety across the board.

By incorporating the team’s expertise, an IoT system can act as a central depository for operating history and the deep, unique technical knowledge the team has developed. Combined with the ability to deliver precise data-driven predictions, this can streamline workflows and enable more informed business decision-making to enhance operations, increase equipment uptime, and maximize production.

Scale and scope

Before implementing any technology solution, it’s important to consider the scope, cost and schedule risk. Oil & gas companies are heavily invested in technology solutions. The idea of ripping out existing systems and starting again is unappealing.

To avoid unnecessarily disruptive, time-consuming, and expensive technology upgrades, look for an IIoT solution that doesn’t require excessive up-front costs, or invasive application or hardware installations. Insist on a solution that can integrate with existing systems, and avoid wholesale changes. Set defined, measurable business goals and implement IIoT on a piece-by-piece basis. Focusing on a small number of assets better manages costs and avoids operational interference.

Dave McCarthy is senior director of products at Bsquare Corp. McCarthy earned an MBA with honors from Northeastern University.