Real-Time Innovations (RTI) says it's the Industrial Internet of Things (IIoT) "connectivity company" and the largest supplier of products based on the Object Management Group's data distribution service (DDS) standard.

In its efforts to build next-generation remote robotics controls, TechnipFMC has selected Real-Time Innovations’ RTI Connext DDS as the connectivity framework for its underwater remotely operated vehicles (ROVs).

Real-Time Innovations (RTI) says it’s the Industrial Internet of Things (IIoT) "connectivity company" and the largest supplier of products based on the Object Management Group’s data distribution service (DDS) standard. In 2017, RTI introduced RTI Connext DDS 5.3, said to be the first connectivity software for scalable system-of-systems database architectures.

The news of the moment is that RTI will supply Connext DDS as an appropriate engine for TechnipFMC’s control system, but what’s behind it is the proliferation of artificial intelligence (AI). In fact, RTI says it "lives at the intersection of functional AI and pervasive networking."

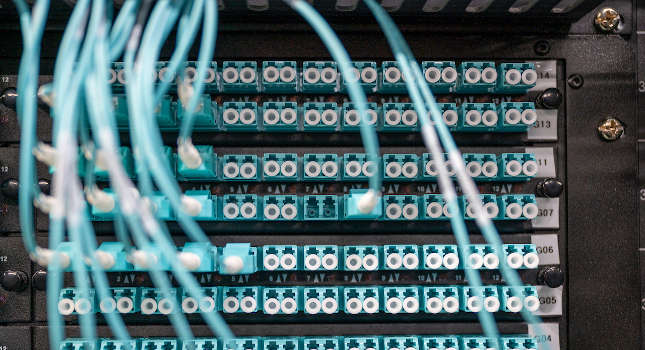

A kind of bus

This software connectivity engine is a kind of bus that sits "above" the physical network. It is used by software developers, including equipment builders and systems integrators, for uses associated with drones, autonomous vehicles, medical devices, and other systems requiring low latency combined with high reliability and resilience, said David Barnett, vice president of products and markets, RTI. Latency is in microseconds, allowing millions of messages per second.

While Big Data applications are likely cloud-bound, real-time applications are more likely found on a chip, although not necessarily so. "The architecture is completely distributed and peer-to-peer. A more typical bus would have a message broker that forwards the data to the controller," Barnett said. "Here a sensor and controller exchange the data directly. There is no single point of failure."

RTI worked with the Object Management Group to define the DDS standard and now adheres to it. "Besides base connectivity, we also provide the infrastructure that surrounds it and that ensures performance, including debug and test, scalability, and enhancements," Barnett said. For example, what’s required to manage hundreds of thousands of medical devices is already in the solution.

"The big opportunity is the move to autonomous systems," Barnett said. "The most common IIoT applications tend to take data from the edge, put it in the cloud, and apply it to something like predictive maintenance. Autonomous applications don’t want to go to the cloud. We’re talking about highly distributed control systems, which require distributed intelligence."

In the skies; under the seas

Barnett noted how airborne drones and underwater ROVs both offer similar challenges. "What RTI provides falls outside the typical enterprise. The DDS protocol allows real-time quality of service tuned for a wider range of networking environments. In the subsea, for example, packet delays can be sent so that instantaneous response isn’t needed. The application itself can define real-world constraints. Finally, if there is a network problem, the application can be put in a safe, secure mode, as needed."

Its developers say DDS is the only framework that provides a peer-to-peer, publish/subscribe architecture. With DDS, each application participates in a data bus that comprises a set of data topics, each defined with its unique, discoverable data model.

The Object Management Group manages both the Industrial Internet Consortium (IIC), a CFE Media content partner, and its standards area. The RTI website notes the OPC Foundation has come a long way in its understanding of the pros and cons of DDS and OPC-UA.