Tools are meant to support actionable insights

Asset management takes care of an asset from the day it is installed to the day it is decommissioned. In between, a world-class enterprise asset management system helps companies get the most out of their resources. Fortunately, company assets are smarter than ever before. As technology continues its rapid evolution, organizations are using complex digitalized assets to improve efficiency, output and safety. As technologies become more advanced, the systems that manage them need to keep pace.

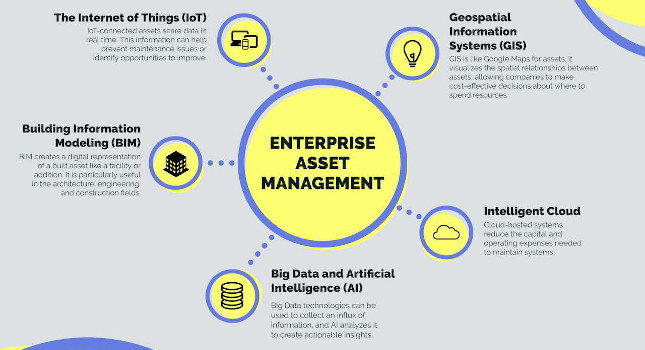

Asset management tools

One important feature of today’s advanced asset management is predictive maintenance. It can prevent equipment breakdowns before they occur. Maintenance is less disruptive than repair. Smart assets and an integrated system can keep asset managers one step ahead.

Technologies that are taking asset management to the next level include the Internet of Things, geospatial information systems, building information modeling, intelligent Cloud, Big Data and artificial intelligence. Each tool manages vast blocks of data to provide actionable insights.

The Internet of Things (IoT): There was a time when mobile telephones simply made and received phone calls. Today, mobile users with an Internet connection can close their garage door, check their home security system or start their robot vacuum from anywhere in the world. IoT is how connected devices talk to one another. Using sensors and cloud platforms, systems like Watson IoT and NordicId allow physical assets to communicate information about how they are performing. IoT-connected assets share data in real time. This information can help prevent maintenance issues or identify opportunities to improve. IoT-based asset management can increase efficiency, raise productivity, automate maintenance, and predict future needs. For example, Lufthansa puts IoT in action. The airline uses an IoT strategy to mine data from its maintenance, repair and overhaul operations and make it available to customers. Real-time aircraft, airport and weather sensor data optimize operations and on-time performance. This focused real-time strategy allows Lufthansa to consistently deliver an exceptional customer experience.

Geospatial information systems (GIS): GIS is like Google Maps for assets. It visualizes the spatial relationships between assets, allowing companies to make cost-effective decisions about where to spend resources. GIS platforms like Maximo Spatial and ArcGIS can help maintenance crews reduce travel time by servicing assets near one another. GIS can also identify hotspots of high-performing or low-performing assets. This makes it especially valuable to organizations such as public works, utilities, and water treatment districts.

The Otay Water District in San Diego County, CA, uses GIS to centralize data from multiple departments. The GIS visualizes topological, spatial, and general relationships and captures how different objects in the network interact with one another.

Building information modeling (BIM): BIM creates a digital representation of a built asset like a facility or addition. It is particularly useful in the architecture, engineering, and construction fields. Platforms such as ModelStream and IBM Maximo provide an end-to-end method for transferring information through the facility’s design, construction, and operational phases. This lifecycle can take years and involve many stakeholders. Without data management, information is often lost in the move from one phase to the next. BIM is a collaborative model that centralizes information and makes it accessible to everyone throughout the entire asset lifecycle. At Heathrow Airport, BIM processes were implemented to maintain data and create efficiency across asset lifecycles. The project saved an estimated 3 to 7% in new infrastructure costs. Hundreds of man hours were saved through automation.

Intelligent cloud: Moving complex enterprise asset management systems to the cloud can yield solid savings for companies. Cloud-hosted systems reduce the capital and operating expenses needed to maintain systems. Platforms such as Microsoft Azure and Amazon Web Services offer agility, scalability, flexibility, and simplified governance to lean organizations. This is an ideal solution for asset-intensive organizations like manufacturing and utilities.

IBM helped Sodexo, a company spread over 67 countries, to migrate 1.2 million assets to the IBM Cloud. The flexible solution implemented one production instance in the U.S. and one in the E.U. More instances can be added anywhere in the world. This allows Sodexo to efficiently manage its data without the issue of clients having to access resources overseas.

Big Data and artificial intelligence (AI): In the IoT era, when everything from valves to vehicles is connected by sensors and systems, there is an abundance of data to be had. Big Data technologies can be used to collect this influx of information, and AI analyzes it to create actionable insights. Connected assets generate more useful data than an old-school analyst with an Excel spreadsheet could ever effectively use. Platforms like Apache Hadoop, Oracle Big Data Solutions, and SAP Predictive Analytics standardize and process this complex information. They can then generate insights that enhance efficiency and maximize return on investment. BMW implemented data mining in its German manufacturing plants to gain insight across a wide range of warranty issues. The information gleaned from this Big Data exercise was used to improve product designs and modify service patterns. The result was a five percent reduction in warranty cases, saving the company more than $33 million a year.

To world-class management

The business world moves quickly, and competition does not rest. Today’s customers have escalating demands, including the expectation of 24/7 operations and rapid turnaround times. Global supply chains and the rising cost of raw materials put additional pressure on companies.

If an entire line can be brought to its knees by a single asset failure, the company is courting disaster. Through predictive analysis, intelligent asset management can reduce or remove the risk of single-point failures.

In addition, world-class asset management also helps companies to run leaner. Predictive analytics can reduce downtime and lower repair costs. Centralized data systems can lighten the administrative burden and cut through some of the red tape between departments, allowing employees to do their jobs more efficiently.

An outdated system may have gaps in data, unexpected asset failures, or stacks of information that was collected but never used. Employees have likely created a series of workarounds to get their jobs done. Upgrading to a more efficient asset management system will reduce waste while getting the maximum benefit from every resource.

Implementing a new system

Implementing a new asset management system is rarely as easy as flipping a switch. The change takes time, effort and resources. But the long-term advantages far outweigh the short-term costs. To make the switch from a legacy system to a new, digitized system, a cultural shift may be needed. Employees need to understand exactly why the system is changing and how it will benefit the company. People often resist leaving their comfort zone. It is important that anyone who will be using the new system receives adequate training. A company that invests a great deal in a new tool but does not train people to use it will not see the benefits of the technology.

Implementation often requires a phased approach. Operations are divided into silos and migrated into the new system one at a time. In that way the new system and legacy system are running concurrently. Companies should take advantage of the opportunity to review the structure of their operations, including where is the company right now and where it wants to be. Like a chance to declutter the operation, migrating to a new system is a prime opportunity to improve processes and eliminate redundancies.

Introducing new, smart assets requires reviewing peripheral systems to make sure the new technology has the support it needs. A new or refurbished asset is a complex system capable of generating and storing data. To optimize that asset, a company needs the ability to use that data.

Information that is collected but never used adds layers of needless complexity to business operations. Modern assets are designed to optimize efficiency. Using them to their full potential means having systems in place that can analyze the data and a workforce trained in using the data to make good business decisions.