To prevent shaft misalignment, incorporate standard maintenance practices.

Learning objectives

- Recognize the causes and consequences of shaft misalignment including how even small deviations can create forces that damage bearings, seals, couplings and increase energy consumption.

- Understand why industry has drifted away from alignment best practices and exploring the role of workforce changes, budget pressures, misapplied condition monitoring and misconceptions around tolerances.

- Apply strategies to reintroduce precision alignment into modern maintenance programs by integrating real-time alignment tools, repeatable data practices and training that builds technician confidence and machine reliability.

Shaft alignment insights

- Shaft misalignment is one of the most common, costly and preventable problems in rotating machinery, yet it remains one of the least understood.

- Despite decades of proven best practices, modern industry has drifted away from alignment fundamentals, creating avoidable failures, wasted energy and unnecessary downtime.

- This article examines the causes, consequences and corrective measures related to shaft misalignment. It also explores why every industry has drifted from standard practices, what this means for critical assets and how realignment, both literal and strategic, is essential for modern maintenance programs.

In modern industry, where uptime, throughput and operational efficiency dominate decision-making, fundamental principles like shaft alignment are often overlooked. While digital technology and automation have revolutionized maintenance programs, the underlying physical relationships between machine components, such as shaft alignment, are often neglected or misunderstood.

This oversight can lead to significant consequences, ranging from increased energy usage, cost of component replacement and premature equipment failure to extensive downtime and safety hazards.

What is shaft misalignment?

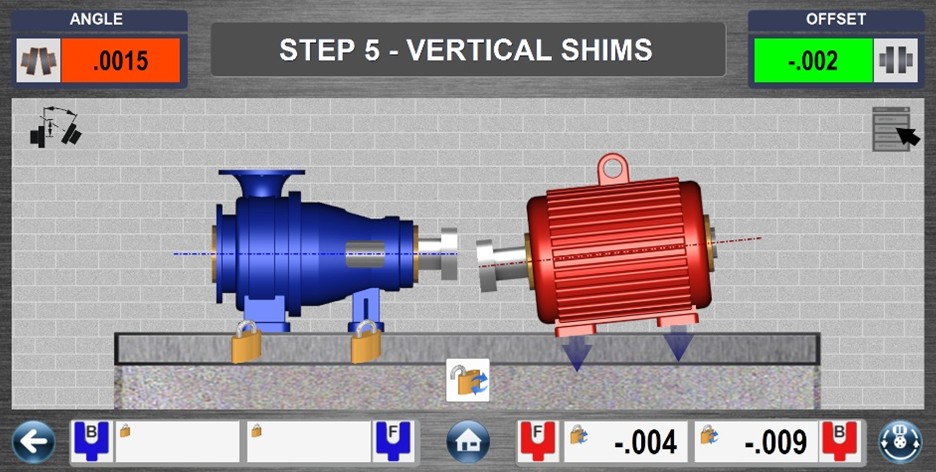

Shaft misalignment occurs when the centerlines of two or more rotating shafts connected by couplings do not form a single, continuous axis of rotation. This can manifest in several forms Including angular misalignment (where shafts are at an angle to each other), offset misalignment (where shafts are parallel but not collinear) and combinations of both (see Figure 2). While this may sound like a minor imperfection, its consequences are anything but.

Over time, even small misalignments generate reactive forces in the rotating machinery, stressing bearings, seals, couplings and other components. These forces result in vibration, noise, heat and, ultimately, premature wear or catastrophic failure. Proper alignment minimizes these forces, allowing smooth and efficient power transmission while reducing mechanical resistance that causes inefficiency and breakdowns, ultimately extending the useful life of these components.

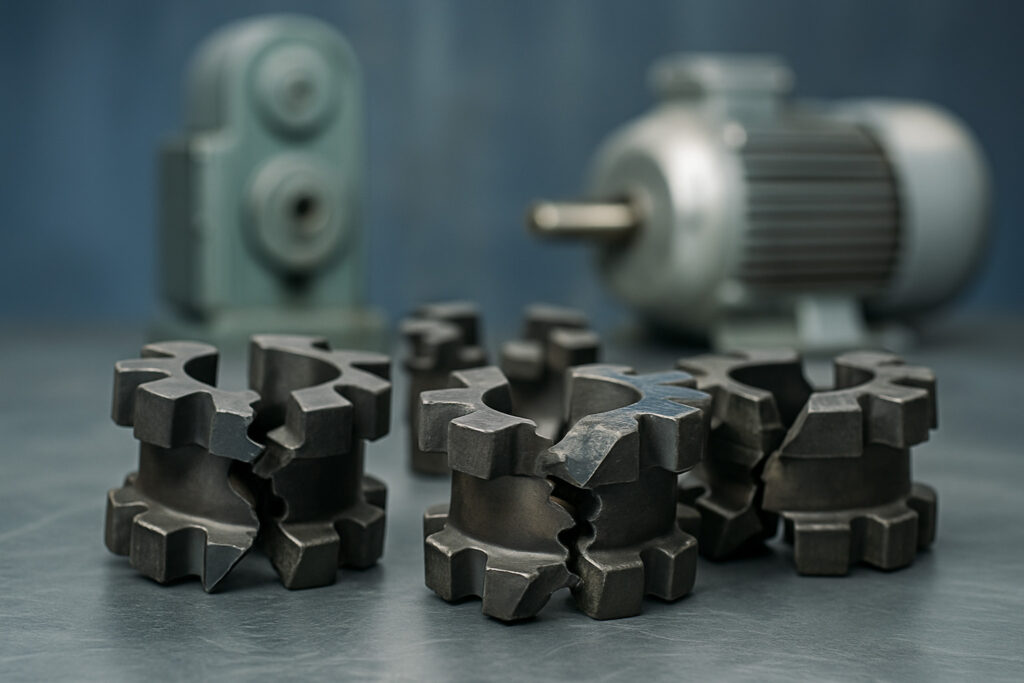

The effects of shaft misalignment ripple through all aspects of machine performance. When alignment is off, bearings experience nonuniform loading, where forces are distributed unevenly across the bearing surfaces, increasing friction and the likelihood of failure. Seals also suffer from premature wear or distortion, leading to lubricant leakage and contamination that accelerates internal damage. Couplings, especially elastomeric and metallic grid types, wear more quickly as they compensate for the misalignment, resulting in increased maintenance costs and unplanned downtime (see Figure 3).

In more extreme cases, misalignment contributes to fatigue in shaft material, which can lead to shaft cracking or breakage. Seals, often the first point of failure, may leak lubricant, contaminating the machine or the surrounding environment. This creates both safety and environmental concerns, particularly in food, pharmaceutical and chemical processing environments.

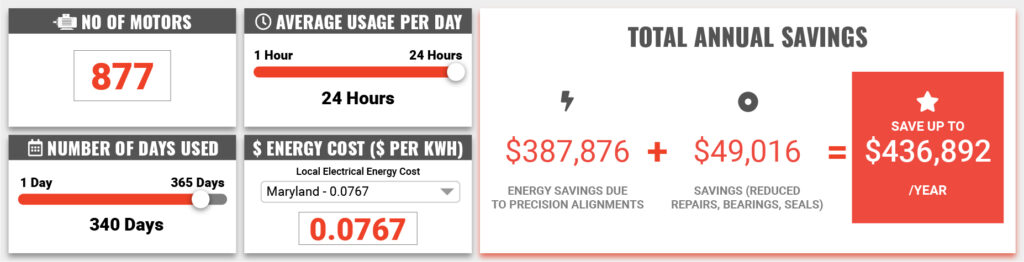

Additionally, misalignment has a direct impact on energy consumption. Poorly aligned machinery consumes more energy due to mechanical resistance, often leading to increased motor loads and overheating. As energy costs continue to rise and sustainability becomes a corporate priority, alignment becomes a key contributor to energy conservation initiatives (see Figure 4).

Why industry has drifted from shaft alignment best practices

Several interrelated factors have contributed to a widespread decline in adherence to shaft alignment best practices across industries. One major factor is the shift in workforce demographics. As experienced millwrights and reliability professionals retire, they take with them decades of hands-on knowledge. Their replacements often lack the same depth of training and familiarity with alignment fundamentals. Unfortunately, corporate and facility leadership often overlook this gap, assuming a two- or five-day training course can replace the deep, experience-based skills developed over decades on the job.

Budget constraints, lack of training, poor implementation of standards and short-term performance metrics also play a role. In many operations, especially those driven by lean or just-in-time methodologies, there’s pressure to get machines up and running quickly, sometimes at the expense of proper alignment. Quick fixes and “eyeball” alignments might get a machine running in the moment, but they often lead to costly issues over time. True proficiency with any alignment tool comes only through consistent, hands-on use.

Furthermore, the proliferation of misapplied condition monitoring technologies has created a false sense of security. Vibration sensors, thermal imaging and ultrasound are invaluable tools, but they are reactive rather than preventive. They detect the symptoms of misalignment, such as bearing noise or heat, rather than addressing the root cause.

Without a comprehensive strategy that includes precision alignment, these tools merely postpone failure rather than prevent it. If managers and technicians perceive alignments as time-consuming and frustrating, they are unlikely to make them part of a comprehensive maintenance strategy. Changing that perception is the key.

Misunderstandings around tolerances and best practices

A critical area where misalignment persists is in the understanding and application of alignment tolerances. Many facilities rely on outdated or overly broad manufacturer specifications or worse, generic “acceptable” tolerances that fail to account for machine type, speed or coupling style. These tolerances may technically avoid immediate failure, but they don’t reflect what’s truly optimal for performance, reliability or life cycle cost. An industry standard tolerances table should be used as a benchmark for setting and verifying alignment quality.

Moreover, technicians often misinterpret coupling tolerances as alignment tolerances. The misconception that “the coupling can handle it” leads to a misleading undervaluation of precision. While some couplings are designed to absorb minor misalignment, doing so consumes their capacity and shortens their useful life. The better approach is always to align shafts as close to collinear as possible, within machine-specific tolerances that consider thermal growth, operational loading and shaft deflection.

The importance of repeatability and data integrity

In a digital maintenance world, data integrity is king. Yet shaft alignment is still often recorded manually or not at all, leaving organizations without verifiable data trails. Without accurate records, it’s impossible to confirm that an alignment was performed correctly or that it contributed to machine longevity. This aligns with ReliabilityWeb.com’s Uptime Elements and RCM Guides, which stress the role of verifiable data and repeatable practices as foundational elements of a reliability-centered culture. This lack of documentation also prevents root cause analysis when failures occur.

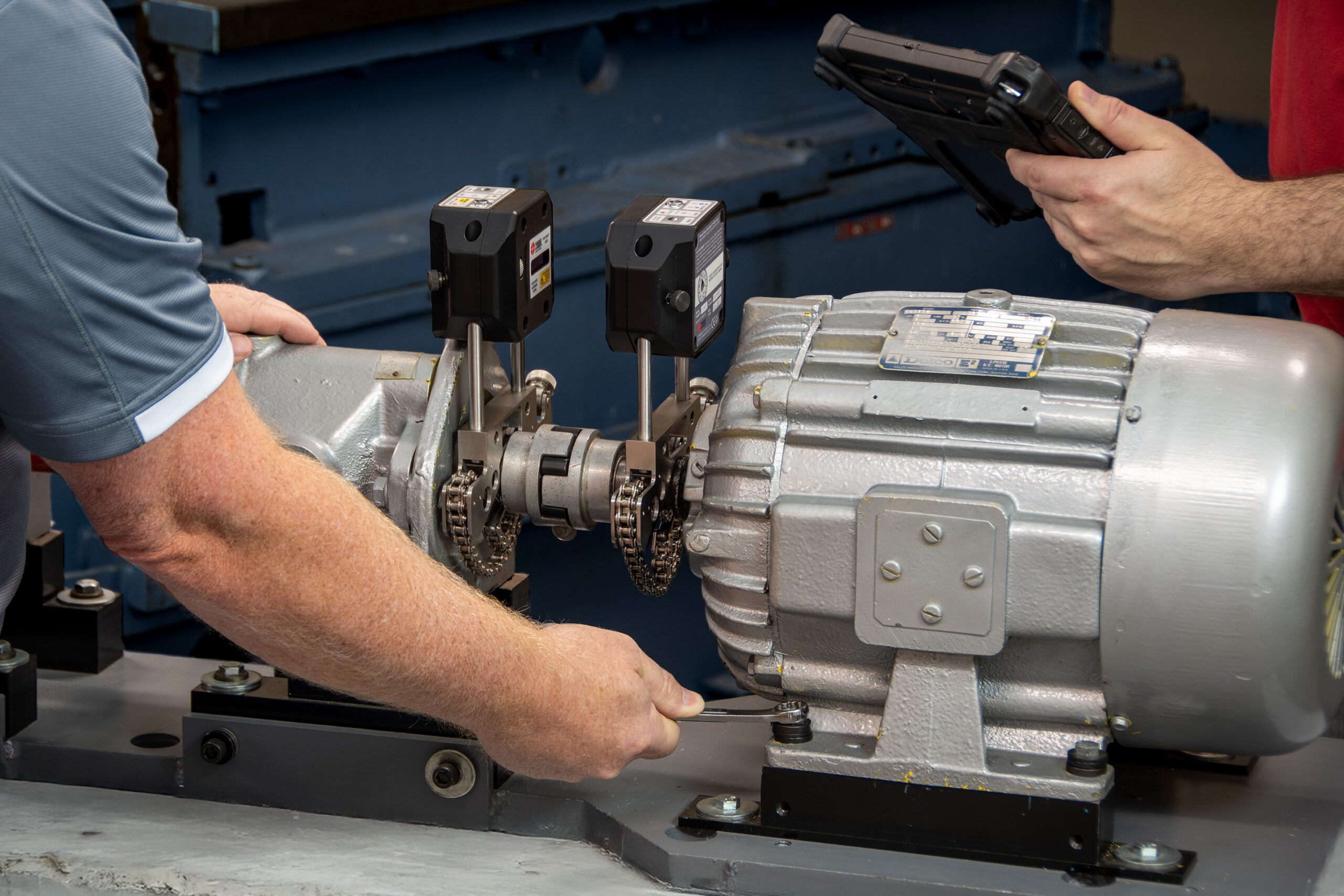

Repeatability is another overlooked concept. A single alignment measurement is not sufficient. Alignment results should be repeatable over several measurements to ensure that mounting conditions, loose bases or soft-foot are not skewing the data. When choosing a tool for shaft alignment, it is important to ensure it includes repeatability functions and quality indicators to build the technician’s confidence and to promote consistent, accurate results during every alignment.

Preventive and predictive shaft maintenance

To reverse the trend, organizations need to reintegrate shaft alignment into the core of their preventive and predictive maintenance programs. This means investing not only in equipment but also in training and accountability. Alignment tools should be as essential as vibration sensors or thermal cameras and used with the same frequency and diligence. Integrating data from vibration sensors, thermal cameras and alignment tools is highly effective for identifying trends and shifting maintenance programs from reactive to truly preventive, an essential step for boosting uptime and reducing maintenance costs (see Figure 6).

Ideally, in addition to vibration checks and thermal profiles, shaft alignment checks should be performed:

- For every installation of new equipment

- After any machine movement or base adjustment

- During scheduled preventive maintenance inspections (especially on critical assets)

- Following any vibration alert or bearing failure

- Whenever couplings, seals or bearings are replaced

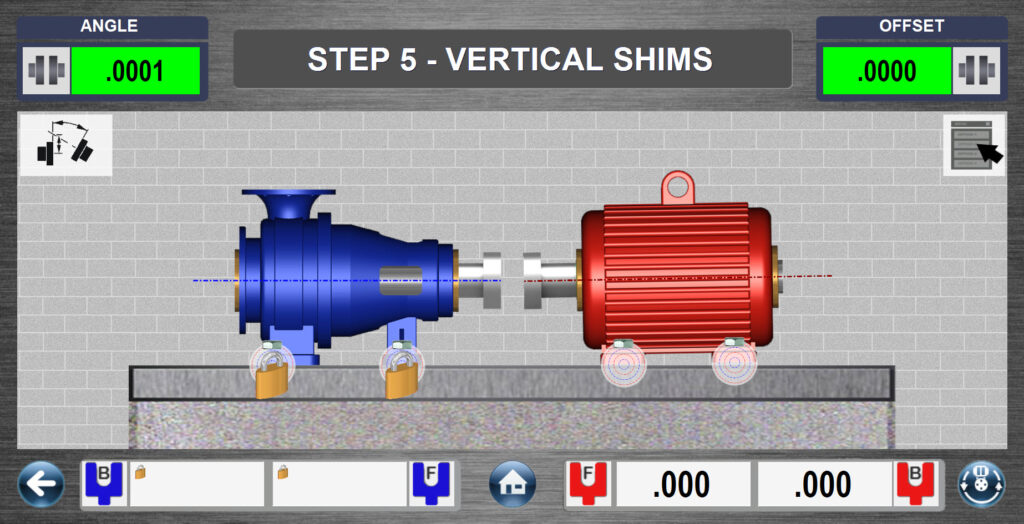

Moreover, alignment should be conducted using tools that provide real-time data, digital documentation and built-in tolerance checks. Seeing the alignment update in real time, as the technician adjusts, greatly boosts confidence and reassures that the tool is helping complete the job both quickly and accurately. Systems that streamline the alignment process while ensuring accuracy are critical for empowering less experienced technicians and raising the standard across the board.

Case study: Eliminating recurring pump failures

In a high-output food processing facility, a critical process pump responsible for moving product through a key stage of production was experiencing repeated and costly failures. Despite routine maintenance and alignments performed using traditional tools like straightedges, dial indicators and an outdated laser aligner, the pump continued to fail on a near-monthly basis. Symptoms included excessive vibration, bearing wear and mechanical seal breakdowns, all clear signs of misalignment.

The frequent pump failures required replacement parts, labor and unplanned downtime that interrupted production and strained maintenance resources. Each failure event typically resulted in several hours of lost output and an average of three hours of labor to swap the pump or replace components. Over a 12-month period, these recurring breakdowns amounted to more than $18,000 in combined downtime and maintenance costs (see Figure 7).

After thorough training on a newly purchased laser alignment tool, it was put to work on the plant’s persistent “problem motor.” The inspection uncovered substantial angular and offset misalignment between the motor and pump shafts, further complicated by a soft-foot condition on one of the motor’s mounting feet.Once the alignment and base soft-foot conditions were corrected using the new laser tool, pump performance improved dramatically. The equipment continued to run smoothly and maintain proper alignment for more than a year beyond its scheduled annual preventive maintenance.

This case highlights how a single, high-precision shaft alignment can deliver lasting benefits, eliminating recurring failures, cutting operating costs and improving overall system reliability, without the cycle of repeated trial-and-error fixes. It also reinforced the technicians’ confidence in the accuracy and value of precision laser alignment.

Case study: Improving uptime with train alignment

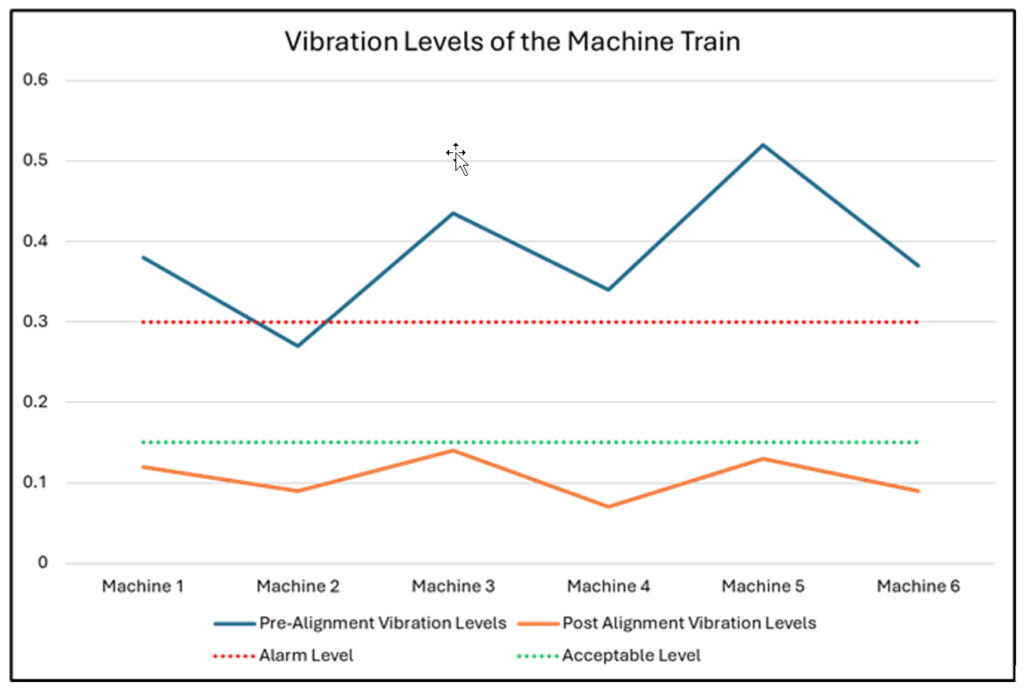

At a pulp and paper mill operating 24/7, a six-machine pump train responsible for circulating critical process water was becoming increasingly unreliable. Each pump and motor pair in the train had been aligned individually in isolation, which failed to account for the interdependencies and thermal expansion effects across the entire system. As a result, the machines suffered from elevated vibration levels, frequent bearing replacements and inconsistent flow rates.

Historically, aligning the entire train would take two full shifts and involved multiple reworks due to their current alignment system and inconsistent alignment results between machine pairs. Using a newer alignment system specialized in the train alignment method, with real-time referencing and visual guidance, the alignment team was able to treat the full machine group as a single unit.

By correcting angular and offset misalignments across all six shafts and referencing alignment back to the stationary machine, the team was able to complete the full train alignment in a single shift, a 60% reduction in time. Technicians remarked on how much easier the process was and how confident they felt in the readings, while the maintenance manager praised the speed, accuracy and reduced downtime the new system delivered (see Figure 8).

Following the alignment, mean time between failures improved by 40% and post-alignment vibration analysis showed a significant decrease in stress on bearings and couplings. The newly aligned system not only reduced maintenance demands, and also improved operational reliability, helping the plant maintain critical uptime goals and avoid unplanned shutdowns.

Shaft precision is not optional

The lack of precision in shaft alignment, leading to misalignment, is a hidden destroyer of industrial reliability, efficiency and profitability. Many companies in industry have drifted from alignment best practices due to training gaps, budget pressures and technological distractions. The path back to precision is critical. It begins with recognizing that precision alignment is not an optional or occasional task, but a foundational requirement for maintaining machinery health.

By reintegrating precision shaft alignment into maintenance strategies, applying best-in-class tools and teaching the importance of precision, organizations can extend equipment life, reduce downtime and improve overall operational performance. In a world that demands more output with fewer resources, precision alignment isn’t just good maintenance, it’s good business.