While machines generated a great deal of attention at IMTS, the human element remains a key component of manufacturing.

We are in a rush to connect every machine with every other machine in an intricate ballet of data and analytics. The promise of the Industrial Internet of Things (please, can we just call it IIoT?) is that our machines will talk with one other, tell us themselves if they are ailing or in need of attention, and provide us with a clear path toward greater productivity, greater safety and better products.

It sounds like a great deal for the machines. So what about us lowly humans?

It turns out there still is room for the human element in manufacturing. That was the overwhelming message at last month’s International Manufacturing Technology Show (please, can we just call it IMTS?) in Chicago. More than 115,000 people attended IMTS in 2016, continuing the growth track of North America’s largest manufacturing trade show and reinforcing that there is still a need for people to get together to look at the machines that will deliver all that productivity.

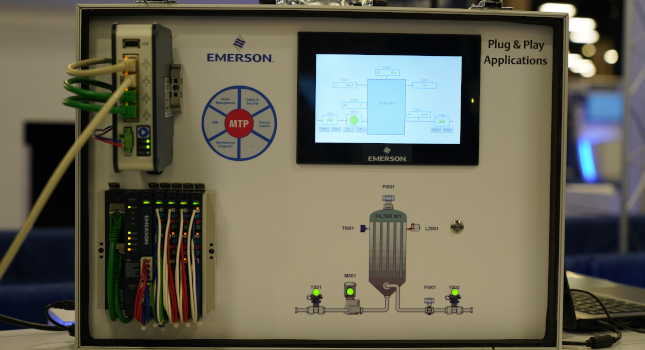

The buzz around IIoT at IMTS (See? Isn’t that easier?) is the interface between machines. Machines have been interfacing with humans for a while now, which we have productized to call the human-machine interface (please, can we just call it HMI?). Data displays on the plant floor have grown to become commonplace, and more importantly, they have become useful tools in allowing workers to have immediate access to information. Not data; information.

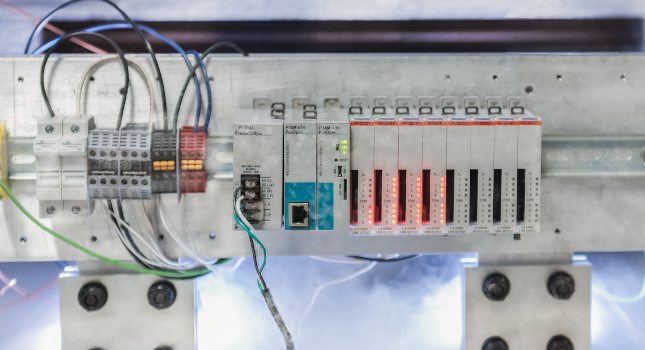

That’s an important distinction. Since the rise of sensors and PLCs (can we please just… never mind) we have been collecting data and using data to manage our operations. IIoT offers the intriguing possibility to turn all of those zeros and ones to help determine not just what is happening on our plant floor now, but what may happen next. Information, and not data, is the key to IIoT’s adoption.

It was one of the subjects at CFE Media’s Global Automation and Manufacturing Summit as part of Hannover Fairs USA’s Industrial Automation North America pavilion. (For those of you playing along, that was the GAMS conference at the IANA pavilion at IMTS.) We discussed the ideas around IIoT deployment, integration and growth with some of the world’s top experts before an overflow audience of people.

We have moved past the education phase of IIoT; we must now begin to deploy it in manufacturing. More than this, we must begin to look at the potential for IIoT to change the way we manufacture and the way our people work. This will require not the installation of machines but the ability for people to work together in new ways and to work with different people to achieve the larger goals of safety, quality and productivity.

All those discussions on the show floor at IMTS and all of the opportunities for suppliers and customers to work together toward better manufacturing were the continuation of what we will call the human-human interface. Some day, I’ll be begging you to please call it HHI. For now, we have to put it into practice before it earns its own acronym.

For all of the spectacular technology we saw at IMTS in this show cycle, we saw something far more profound—that the relationship between people is still the critical driver in manufacturing. Those who came to learn were given a crash course in all that is new. Those who came to sell found a more optimistic buyer who wants to quantify the investment’s ROI (and if I have to explain that one, you’re reading the wrong magazine.)

If IMTS is to be the real success its numbers indicate it is, our next step is to get all of our humans together and start that interface.