Nevada is touted as a leader in “clean energy revolution” at plant opening.

It’s not much of a gamble. Besides casinos and shows, Las Vegas also has clear skies and desert heat. That’s one main reason thermal power manufacturer Ausra has opened a 130,000-square-foot manufacturing plant that will not only make solar thermal power components, but also will be run on solar energy .

The plant, built just outside McCarron Airport, was opened June 30 with the kind of fanfare you’d expect for such an announcement at a time of rapidly escalating fuel prices for manufacturers.

” Nevada is poised to be a leader in the clean energy revolution,” said Nevada Sen. Harry Reid (D). “This facility will help position our state as the premiere place to invest in these new technologies,” he said. “As the factory expands operations and we continue to invest in clean energy, we’ll create thousands of good-paying jobs and keep our outdoors pristine for future generations.”

Reid also said the U.S. government should do more

“This is a crossover point for this industry,” said Ausra president and CEO Robert Fishman at the press conference .

“Ausra’s factory is accelerating Nevada’s and America’s solar future by tripling worldwide manufacturing capacity, relieving the supply constraint that has slowed the industry, and continuing to drive down costs,” Fishman said. “By a 94% majority, the American public wants solar power development to help address rising prices for traditional energy sources. We’re ready to respond now with a clean, reliable and cost-competitive energy choice that will be an economic development machine for the country. Here in Southern Nevada alone, developers are planning over $50 billion of future solar power plants.”

That’s one reason Ausra figures to do well. The company already has an order

with California utility Pacific Gas and Electric Company announced a power purchase agreement for a 177-megawatt solar thermal power plant to be built in central California. The power plant will generate enough electricity to power more than 120,000 homes.

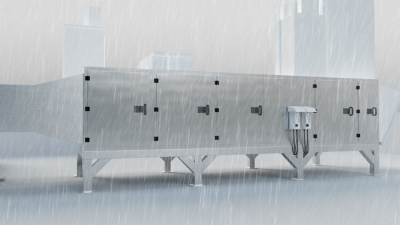

Ausra’s Las Vegas manufacturing center will make solar field equipment for the PG&E project ,for other power projects throughout the American Southwest and for Ausra’s process steam customers, who are adopting solar thermal power to lower their fuel costs and emissions in their operations, including food processing, enhanced oil recovery and refining and pulp and paper manufacturing.

The Las Vegas facility will employ a staff of 50. At full capacity, it will annually produce more than 700 megawatts of solar collectors — enough to power nearly half a million homes, and keep 1,400 construction workers employed building solar power plants.

Ausra’s Compact Linear Fresnel Reflector solar technology captures the sun’s power to produce electricity without pollution. Mirrors focus sunlight to heat water pipes, and the resulting steam drives a turbine to generate electricity.