Recognizing opportunities in new instrumentation designs can provide the basis for greater productivity throughout the industrial plant, particularly in maintenance.

Recognizing opportunities in new instrumentation designs can provide the basis for greater productivity throughout the industrial plant, particularly in maintenance.

Over the past few years, there has been a growing interest in making maintenance more productive. Various philosophies and catch phrases have emerged to express the various ways of maintaining equipment that have developed. Some of these include total productive maintenance, reliability centered maintenance, and profit centered maintenance. All of these, plus a few more, have some common threads in terms of methods proposed for improving productivity.

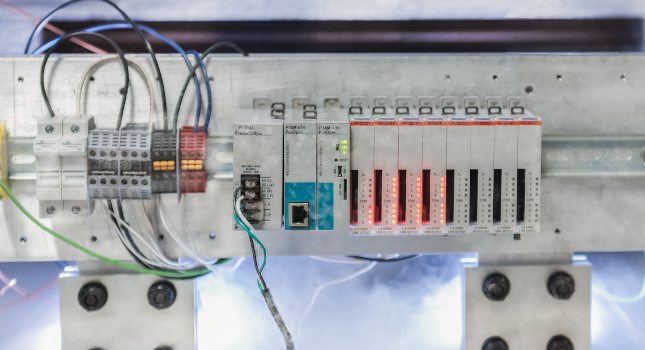

One recurring theme is the use of technology to improve preventive and predictive maintenance. This approach includes easy but secure access to test and measurement data wherever they are needed for analysis and action. Today, changes in test and measurement equipment are providing opportunities to expand the benefits of preventive and predictive maintenance. Two primary factors are working to bring about these changes:

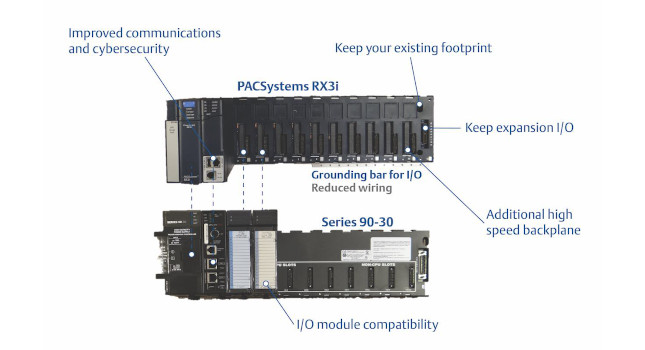

– PC platforms that eliminate the need to open the computer to connect measurement and data acquisition cards

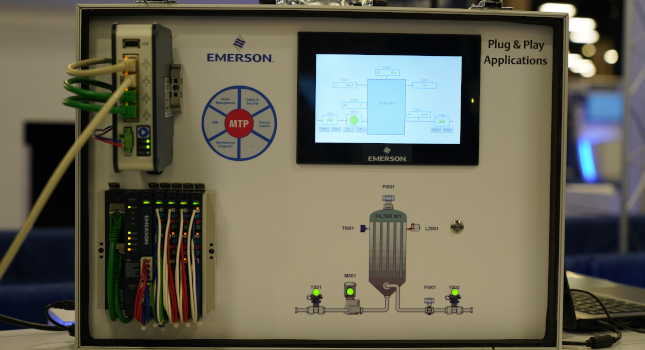

– Network communication interfaces that require no additional cards and that provide true plug-and-play connectivity.

Measurement and data acquisition equipment are evolving to take advantage of these changes. For example, new instrumentation designs:

– Feature form factors that provide easy plug-in to a PC’s universal serial bus (USB) or IEEE-1394 (Firewire) data communications port. Users will have access to measurement products that combine the low cost of PC plug-in cards and data loggers with the high levels of precision required today.

– Use software tools that greatly simplify networked measurements. Users have access to instruments with embedded internet protocols that allow online measurements over popular, easy-to-use web browsers.

– Provide communication pathways that support automated measurements and software that allow data to be distributed wherever it is needed in the plant. Authorized users have remote access to data and can easily reconfigure permanently installed measurement devices.

Sharing data throughout the enterprise

A maintenance test database may be used by many people and multiple departments for different purposes. For example, plant engineers use data to discern trends and adjust preventive maintenance schedules. Maintenance managers use data to anticipate spare parts requirements. Manufacturing engineers use the database to help establish specifications for new equipment purchases. Accounting uses the data to assist in budget forecasting.

The fundamental requirement for realizing the potential of a test and measurement database is instrumentation design with embedded operating systems and web servers that essentially allow universal connection and use (see illustration). Still, the proliferation of portable instruments with data ports, palmtop computers, and wireless, data-anywhere networks makes decisions about database formats, development tools, and user support more complex. In some cases, users are looking for database access not from a personal computer, but from a specialized workstation, instrument, or process controller.

Increasingly, maintenance managers and engineers must address these challenges as new hardware and software are purchased. Past practices, such as using manual data collection systems or simply saving data to disk on the maintenance department’s PM system, are no longer acceptable. Similarly, the days of satisfying only maintenance needs with custom analysis programs and limited reporting are also disappearing.

Although these concepts may at first be intimidating, the number of tools available for transferring and sharing data easily have increased. The latest data acquisition software packages have helper functions in the form of wizards and drop-in components that provide networking connectivity and database support. Using these built-in software extensions makes many of these underlying complexities transparent, allowing the plant engineer and the maintenance manager to manage data collection and distribution more easily.

Reaping the benefits

Learning to apply these new technologies opens the door to productivity improvements throughout the enterprise. Ultimately, their use contributes to lower costs and higher profits.

One way to make these improvements happen is by taking steps to ensure that preventive maintenance is a truly closed loop system. Such a system uses the test database to help establish machine condition-based maintenance, and thereby optimize preventive maintenance intervals. Conversely, test data also help locate and track problems until they are corrected. These activities may include failure mode and effect analysis. Then steps can be taken to prevent a recurrence of problems.

Another way is to set aside time for training. Test engineers and technicians must know how to wring the full benefits from advanced technologies. Vendors often can help by supplying application assistance that minimizes the time required to get new systems and software installed and operational.

Of course, these techniques and data must be combined with results measurements to determine their impact on the bottom line. Investments must be economically justified. Typical results measurements include such items as repairs/1000 hr of machine operation, mean time between failures, output per operating hour, parts inventory reductions, and the like. Although it may be difficult to quantify all bottom-line benefits of new instrumentation systems, their added capabilities compared to older systems alone may be sufficient justification.

Joseph P. Keithley has been chairman and CEO of Keithley since 1993. Prior to that, he served as the company’s chairman of the board and vice chairman. He holds BS and MS degrees in industrial engineering from Cornell University and earned an MBA with distinction from the University of Michigan.