A recent NEMA study indicates a strong demand for industrial controls. From Sept. through Dec. 2006, the organization’s Primary Industrial Controls Index leaped almost 8% — its largest jump in 14 years. Even the broad Primary Industrial Controls and Adjustable Speed Drives Index increased 5.6% during that same period. The index showed a 4% gain from the fourth quarter of 2005, which makes 13 straight quarters of year-over-year growth.

The index gain is ahead of the Nation’s economy; U.S. GDP grew at a rate of 3.5% — more than was expected. General economic growth is attributed to the housing market, consumer spending and export demand. However, the manufacturing sector decreased for the second time in three months. Manufactured goods production has slowed while businesses sell off stockpiles to correct inventories. But manufacturing should pick up the pace after companies work through this inventory cycle.

NEMA’s Electroindustry Business Confidence Index shows the electroindustry taking a breather from its previous strong performance. But contrary to this, industrial production of core electrical equipment — including industrial controls — surged 13% between Dec. 2005 and Dec. 2006. The electroindustry’s capacity utilization rate was 85% during the fourth quarter of 2006 and remains well above its historical average of 82%. NEMA predicts that demand for industrial controls and adjustable speed drives will remain relatively high for the near term.

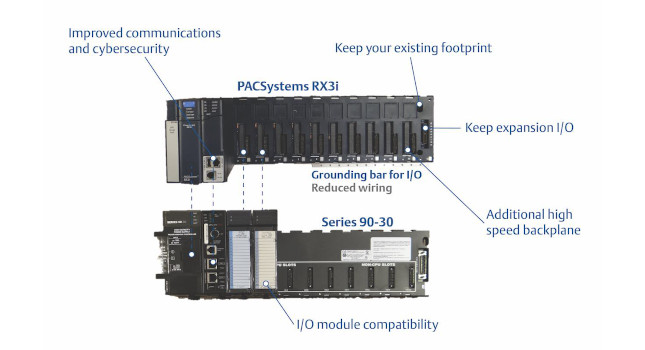

The Primary Industrial Control Index represents U.S. shipments for motor starters, contactors, terminal blocks, control circuit devices, motor control centers, sensors, programmable controllers and other industrial control devices.

NEMA data collection program was expanded to include adjustable speed drives in 2001 because of the energy-saving role they play in industry. Including drives in the index provides a broader measure of the industrial control marketplace, according to NEMA.