In an upcoming June 20 webcast, learn about the fundamentals of arc flash mitigation and the standards required to keep workers safe.

Arc flash and electrical safety are critical aspects in a manufacturing facility. Knowing and understanding the fundamentals often mean the difference between life and death. Companies and workers need to stay on top of the electrical codes so they can better protect themselves from a potential accident.

On June 20, webcast presenters H. Landis Floyd and Bibek Karki will explain what workers need to know and how to stay safe in the webcast “Electrical safety: Know the fundamentals of arc flash mitigation.”

Click here to register for the webcast.

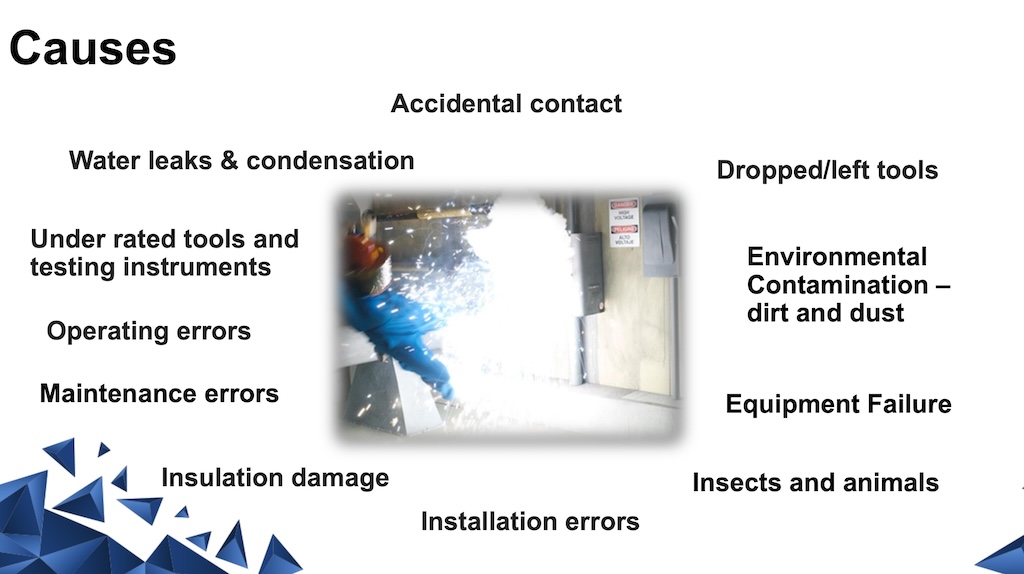

In a manufacturing facility, an arc flash is a dangerous release of energy caused by an electrical fault that occurs in equipment such as circuit breakers, switchgear and other electrical components. This can happen during normal operation of the equipment, as well as during maintenance or repair. The intense heat and bright light generated by an arc flash can cause severe burns and other injuries to workers, as well as damage to equipment and facilities.

An arc flash event can be triggered by several factors such as human error, equipment failure, corrosion, dust, moisture and others. Such an event can happen in several ways, such as a short circuit, a ground fault, a loose connection or a failure of insulation.

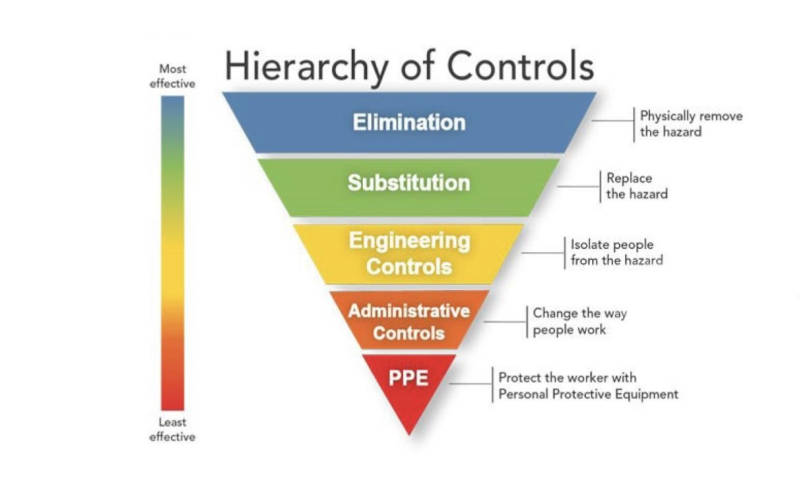

The presenters also will examine the consequences of an arc flash incident as well as the codes required to keep workers safe from potential incidents and give them the tools to make better decisions.