How do we get our plant to be a Top Plant so that we can improve our competitive position in global manufacturing? Many manufacturers apply various tools and strategies to achieve this, while others simply move to other countries to get cheaper labor. But is this really working? There are more important issues to address than the tools themselves: leadership, alignment, teamwork, innovation...

How do we get our plant to be a Top Plant so that we can improve our competitive position in global manufacturing? Many manufacturers apply various tools and strategies to achieve this, while others simply move to other countries to get cheaper labor. But is this really working?

There are more important issues to address than the tools themselves: leadership, alignment, teamwork, innovation — including at the shop floor level and change management. And, there are numerous studies that indicate doing cost cutting to get lower costs simply does not work (I haven’t found any that say otherwise). Costs will come down if you get your practices, processes and systems right, but cost-cutting is typically neither effective nor sustainable.

Here are a few sustainable ways to put any plant on the road to becoming a Top Plant:

Leadership — Leaders set the example and have the courage to support and defend their basic values and principles. Leaders are trustworthy and true to their word and principles, thus creating a sense of trust. Leaders convey an overall vision and sense of purpose, while firmly grounded in reality. Leaders have a passion for excellence, set high work and ethical standards and create a caring yet disciplined environment. Finally, and perhaps most importantly, leaders put people first, treating them with dignity, respect and appreciation. Put simply, leaders create an environment where others want to follow them. How many corporate ‘leaders’ create this kind of environment? My experience has been that very few do — except for Top Plants.

Alignment — A recent employee survey by Harris Interactive Research found:

20% of employees were enthusiastic about organizational goals

20% saw a clear connection between their tasks and organizational goals

15% felt the organization enabled them to achieve their goals

15% felt they were in a high-trust environment

13% felt there was a high-trust, highly cooperative working relationships with other groups or departments.

Even if the survey was wrong, and the numbers are twice as good as this, it still speaks poorly of most organizations’ ability to align its people to a common strategy and set of goals. I agree wholeheartedly with Peter Wickens, author of “The Ascendant Organization,” that one of the most important things a CEO can do is to align the organization. Top Plants are well-aligned.

Teamwork — My experience has been that effective teams require:

Clear purpose and direction, including a sense of meaning aligned to corporate strategy

Boundaries for the empowerment given, but self determination within those boundaries

Openness and honesty in working as a team and rules of conduct for that

Verification of skills to operate within the boundaries, or training needs thereto

Measurement of effectiveness as to its impact on the business

Continuing feedback and support from the team’s sponsor

Flexibility to address changing needs, e.g., boundaries, training, measures, etc.

If you cover these issues reasonably well, you’re more likely to be happy with the team’s results. If not, there’s a much greater risk in having an ineffective team. Top Plants foster better teamwork.

Innovation — Many companies spend a lot of money and energy on ‘big’ innovation — the next big breakthrough in technology. While I applaud this, what concerns me is that they forget the ‘little’ innovation, that is people on the shop floor coming in and making things just a tiny bit better, every day. Most organization leaders apparently don’t understand their role in removing the obstacles that would make it easier for the people to make these little improvements day to day.

If everyone in the company made just one tiny improvement every day, think of the leverage that creates in reducing costs, and improving the gross profits that fund the ‘big’ innovation for creating new products and markets. Think of the impact this would have in better aligning the organization. A regular refrain in many companies is that “our people are our most important asset.” Yet those same companies don’t seem to hesitate to dispose of those assets in an attempt to become more competitive.

Innovation and continuous improvement must permeate the organization at all levels, and leaders must create an environment where this happens, removing the obstacles from the employees’ ability to make those day to day improvements. Top Plants engage the shop floor to develop ‘little’ innovations to make plant floor improvement routine.

Change Management — I believe that people want to change if there’s something in it for them and if they participate in creating the changes. It’s up to the leaders of the organization to articulate how the change is beneficial to the employees, then help them create the changes. We must help them create, removing the obstacles that hinder their creativity, helping them to solve the day-to-day problems, so that the organization gets a little better every day. Managing change is fairly straightforward:

Articulate a compelling reason for change, and how employees benefit from the change

Communicate your strategy and the goals desired, again, and again and again

Apply leadership and management principles: leaders like change; managers like stability — a process for managing both and getting the balance right is essential

Facilitate employee implementation of the change process — ‘people own what they create’ — help them create the changes and improvements

Measure the results; reinforce good behavior; challenge bad behavior

Stabilize the change/organization in the new order through procedures, standards, audits; management stability is critical

Repeat the process — change and improvement is a normal part of the organization’s behavior.

If we get these practices right, any tool will work. If we don’t, no tool will work.

Focus on the long-term

So, just how does a plant get to be a Top Plant? Certainly the tools help, but long-term success and sustainability begins with a focus on long-term thinking, even at the risk of lower short-term profits; then understanding and mapping the processes used, and eliminating the waste in those processes; engaging employees and suppliers in problem solving — especially avoiding threatening employees with layoffs; then selecting the tools and practices that will best engage the employees in helping the company be more successful.

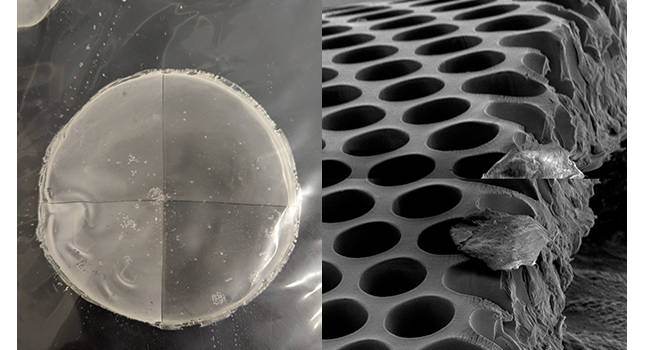

The drawing shows a hierarchy for applying various tools and strategies, including Six Sigma, Kaizan, Lean and others. It’s not meant to suggest that you must always use these in the order presented. However, I believe that the tools and strategies used in the order presented will provide you with the greatest likelihood of success.

Author Information

Ron Moore is the Managing Partner of The RM Group, Inc., and author of “Making Common Sense Common Practice: Models for Manufacturing Excellence,” from Elsevier Books, Butterworth-Heinemann Imprints. He can be reached at (865) 675-7647 or by e-mail at [email protected] .