H. Landis “Lanny” Floyd, partner and principal consultant with Electrical Safety Group Inc., tackles unanswered questions from the April 21, 2016 webcast on electrical safety programs.

H. Landis "Lanny" Floyd, partner and principal consultant with Electrical Safety Group Inc., tackles unanswered questions from the April 21, 2016 webcast on "Arc Flash University: A Checkup on Your Electrical Safety Program."

Q: What are the current statistics for Arc Flash Fatalities and changes in the NFPA-70E lockout tagout?

H. Landis "Lanny" Floyd: The most recent analysis of U.S. occupational electrical injuries and fatalities is from the Fire Protection Research Foundation. The report, " Occupational Injuries from Electrical Shock and Arc Flash Events" can be downloaded free of charge here.

Q: How does one evaluate a poorly performed arc flash study and a well-performed one?

Floyd: The IEEE standards working group responsible for IEEE 1584, Guide for Arc Flash Hazard Calculations recently published a supplement. IEEE 1584.1. This supplement provides guidance on assuring a quality study. An excellent article that covers this is by Jim Phillips, a member of the IEEE 1584 Committee. It is available here.

Q: What’s the difference between clothing testing procedures and actual arc flashes in equipment?

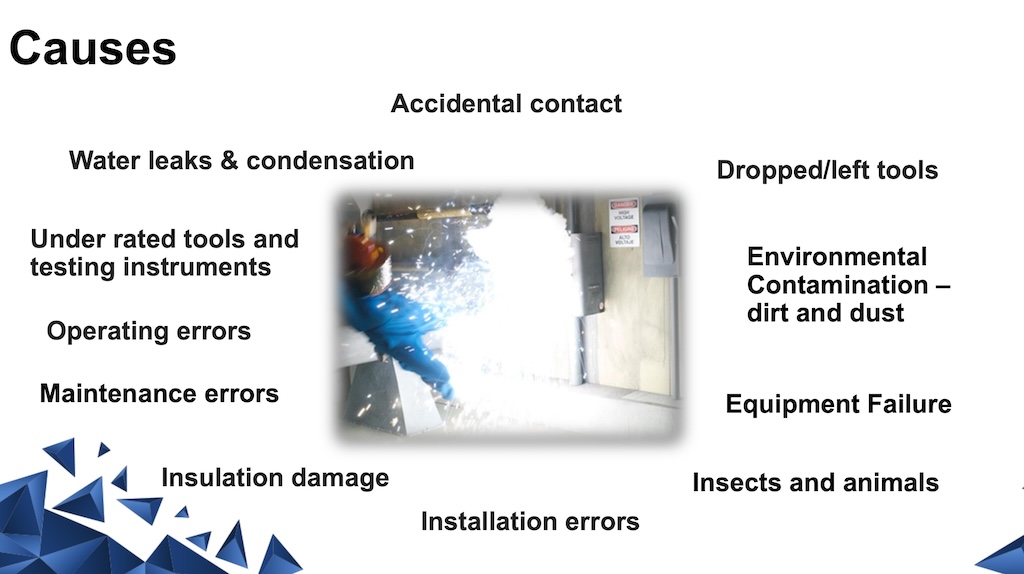

Floyd: Clothing testing procedures are conducted according to ASTM standards that minimize variables and assures repeatability at different testing laboratories. Actual arc flashes in the workplace occur with many variables that are not controlled.

Q: How do you feel about proper labeling of safety risks on site?

Floyd: Warnings and labels providing information on hazards and risks should be part of your electrical safety program.

Q: Is there a program available that you recommend to educate non-qualified-electrical personnel enough to perform electrical task?

Floyd: There are several well respected training organizations you could consult with. Shermco Industries, AVO International, and eHazard are three I am familiar with.

Q: Is NFPA looking at revising the Restricted Approach boundary again in 2018? The change from 12" tp 1" for 480 circuits was a major shift.

Floyd: I am not aware of any changes to the restricted approach boundary for the 2018 revision. I think you are incorrect on the change you indicated. The 2012 and 2015 editions of NFPA70E did not change the Restricted Approach Boundary for 480V. It is 1.0 feet.

Q: NEC and NFPA indicate that as long as a panel door is closed you are safe and need no PPE—yet, if that panel is on a bus that "sees" a failure that creates an ARC Flash, that door now becomes a projectile—is this an issue being reviewed by NFPA / NEC?

Floyd: I don’t agree that the statement is correct. NFPA 70E article 130.5 requires a hazard analysis and risk assessment to determine what safe work practices and PPE is required. Unless the equipment is arc rated, you should take into a consideration that exposure to arc energy may be possible, even if doors and covers are intact.