At a recent arc flash seminar, the speaker asked the attendees "How many of you work at a plant that has an up-to-date one-line diagram?" He prefaced this question with an explanation of what up-to-date means — not only an accurate drawing, but also the documentation that supports the one-line diagram.

Sections: Coordinating protection devices Energized equipment Arc flash and documentation accuracy What a one-line diagram should include More Info:

At a recent arc flash seminar, the speaker asked the attendees “How many of you work at a plant that has an up-to-date one-line diagram?” He prefaced this question with an explanation of what up-to-date means — not only an accurate drawing, but also the documentation that supports the one-line diagram. Accurate electrical documentation must match your plant’s electrical system. Period.

So how many people in attendance at that seminar raised their hands?

Not one person.

Among the companies listed on the roster, many were highly respected names in manufacturing. Not one could boast an accurate one-line diagram.

There is an alarming number of manufacturing plants operating without accurate one-line diagrams.

The one-line diagram is the most important drawing a plant can have for understanding its electrical system. A one-line diagram is a drawing in which a single line represents three phases of a 3-phase power system (see “What a one-line diagram should include”). If properly drawn, it shows a correct power distribution path from the incoming power source to each downstream load — including the ratings and sizes of each piece of electrical equipment, their circuit conductors, and their protective devices.

Coordinating protection devices

Regardless of which protective devices you use, they must be coordinated with regard to their time/current curves and with each other. But, if your one-line diagram is not accurate, it is virtually impossible to achieve protective device coordination.

John Lane, Principal Electrical Engineer, AVO Training Institute, Dallas TX explains that “Protective devices, such as fuses, circuit breakers, and relays, have curves that are plotted on a log-log graph that shows current with respect to time. Protective device coordination requires setting the devices according to these curves, so that when a fault occurs, the upstream protective device closest to the fault opens as rapidly as possible to minimize risks to people and equipment, as well as to isolate the problem with minimum disruption to the rest of the plant’s electrical system.”

Devices with longer delay times help protect expensive processes. Protective devices with time/current characteristics that minimize nuisance tripping help keep processes running — especially with large motors that require significant starting current. But such configurations can increase available fault current significantly.

Conversely, protective devices that trip or clear instantly reduce the amount of available fault current. But instantaneous fault clearing tends to increase nuisance tripping.

Some plants make provisions for electrical workers to substitute protection devices that clear instantaneously if it is absolutely necessary to work on live circuits. When repairs are done, the devices with time delays are returned to normal service. This approach protects workers by limiting available fault current during the time they are exposed to the risk, while maintaining protective device coordination during normal process operation. This ensures that processes continue and production is not interrupted. However the danger is that electrical workers increase the time they must work near live circuits because they must perform the protective device changeovers. Also, if the correct protective devices are not placed back into normal operation, coordination could be compromised as well as the safety of the electrical workers.

The trick is to achieve an appropriate balance between protection and production. Proper protective device coordination means finding that elusive perfect balance between maximizing worker safety and maximizing process uptime.

Energized equipment

Most plants have some type of lockout/tagout (LO/TO) procedure in place. OSHA’s LO/TO requirement is not new. At least at some level, some equipment is tagged out for service. Point is, common sense suggests strongly that the power must be off if equipment is to be serviced. OSHA prevails where common sense fails.

But don’t we all know people who have worked on equipment and circuits live? Yes. And don’t we all know that there are some situations where it is necessary to work on, or be around live circuits? Yes. And don’t we all know of people who have been injured by working on circuits from which they thought power was removed?

OSHA requires in its 29 CFR 1910.333(a)(1) that “live parts be deenergized unless the employer can demonstrate that the deenergizing introduces additional or increased hazards.”

The 2004 release of NFPA-70E includes language that details requirements of an energized electrical work permit, which calls for written authorization for work on or near a circuit that is energized at 50 V or greater. According to Kenneth G. Mastrullo, CPE, Senior Electrical Specialist, NFPA, “The energized electrical work permit provides the written documentation to prove that it is infeasible to work on the equipment or circuits deenergized as required by the OSHA regulations.”

Feasibility is a tough requirement to fulfill. However, NFPA has made the provision for doing so. After clearing the feasibility hurdle, the permit intends to verify that electrical workers as well as those requiring work to be done are fully aware of, and fully understand “the hazards, and that proper training, procedures, and techniques are in place and are being used.”

Mastrullo emphasizes that the “energized electrical work permit also provides accountability for work policies and procedures.”

Why risk an injury by working on live electrical circuits — especially now that NFPA-70E requires a paper trail and accountability for doing so? Strive to deenergize, lockout, and tagout properly. But to do so, you must have accurate electrical system documentation.

Arc flash and documentation accuracy

Available fault current is directly proportional to flash protection, limited approach, restricted approach, and prohibited approach boundaries. Available energy depends on current and time. Electrical system impedance affects the magnitude of fault current directly. Fault current clearing time depends on the protective system. An accurate one-line diagram of your electrical system is crucial to determining available fault current.

Lane stresses the necessity of a one-line diagram that matches the plant’s electrical system as a starting point in assessing arc flash hazards. Lane says, “Every electrical distribution path in every plant is different. Each component in each of

these paths is a variable that must be considered when evaluating potential arc flash hazards. An arc flash hazard analysis is more than recommended — it is urged.”

What a one-line diagram should include

One way to ensure that your plant’s one-line diagram is accurate is to appoint a qualified and responsible person to be “in charge” of keeping this critical document up-to-date. This person must be a trained electrical professional, should be knowledgeable about the electrical history of the plant, empowered to make changes in documentation and policy, and accountable for this process.

One-line diagrams can be maintained using the tried and true CAD program. However there are a number of software packages that analyze electrical power systems, ensure one-line diagram accuracy, manage changes and revisions, and even perform arc flash hazard analysis. Regardless of the tools used, it’s important to keep your one-line diagram and associated electrical documentation accurate.

A one-line diagram of a plant’s electrical distribution system should include:

Transformer ratings, voltage ratio, impedance, and winding connections

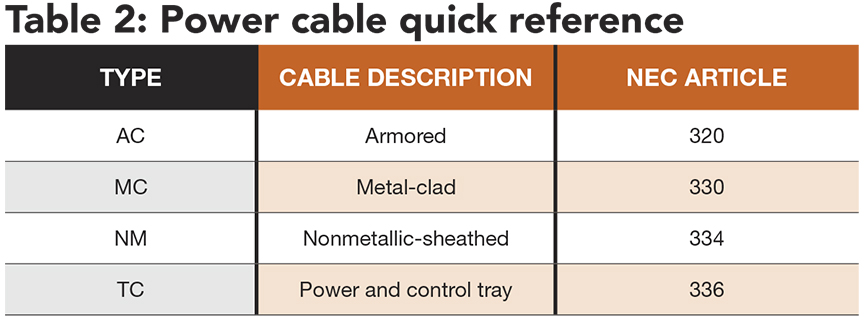

Feeder cable phase, neutral, and ground sizes; length of cable, conductor material, and conduit size and type

Switchgear, switchboards, panelboards, MCCs, fuses, circuit breakers, automatic transfer switches, and continuous current ratings

Protective relays with appropriate device numbers, and CTs with associated ratios

Detailed legend indicating device types, identification, and other significant details.

More Info:

For more information on arc flash, NFPA-70E, and electrical documentation accuracy, go to plantengineering.com or nfpa.org .

Don’t miss the latest WEBCAST in Plant Engineering magazine’sarc flash series, September 30 at 10 a.m. CDT . The webcast — “Protecting people and equipment from arc flash” — addresses electrical documentation accuracy, protection devices available to increase worker and equipment safety, and the knowledge to make all these pieces fit together. Go to plantengineering.com to register.