Shifting from being purely functional to highly analytical, operators have become an increasingly critical part of today’s business processes—significantly changing the way businesses operate and adding more value than ever before.

As businesses strive to gain a competitive advantage from their operations, the way operators perform their work has evolved. Shifting from being purely functional to highly analytical, operators have become an increasingly critical part of today’s business processes—significantly changing the way businesses operate and adding more value than ever before.

While operators of the past were trained to function in their roles with in-depth linear knowledge and to continually follow the process within established guidelines, their role has evolved significantly with advancements in technology. Operators are increasingly required to engage beyond their traditional functional boundaries and to collaborate within a cross-functional role for increased business agility.

To advance operator effectiveness, the latest software solutions enable operators to better leverage information in both routine and critical conditions for optimal decision making. There is a growing need for tools that enable them to collect, connect, analyze, and act upon vast amounts of real-time operations data, supporting a more engaged and intelligent workforce.

The operator of the past

The manual demands of yesterday’s operator required an in-depth knowledge of process and machine operations, as well as of the systems that enable the process. These operators often learned from previous operators, sometimes through trial and error, and worked within a predefined set of parameters. They made decisions based on the way they were trained and strived to comply with established guidelines and procedures to maintain status quo.

There was a great deal of linear knowledge within these operators’ specific functions, where the boundary of much of their work would occur. In many cases, the more operators an employer hired, the better a system ran because each operator would focus on a specific machine and/or part of the process that made him or her an expert.

Many employers today utilize a streamlined team-based approach whereby workers are cycled through many jobs to not only enable knowledge sharing and continued professional growth, but also cover the lack of company funding for expert operators for each step of the process. This has been effective for many companies, yet the adoption of advanced software is key to further evolve their teams with greater efficiency.

Today’s operator

The modern operator has evolved into a multifaceted employee, which has drastically increased the role’s responsibilities as a “generalist,” solving problems in real time and not specifically being an expert in merely one section of the process. Today, the operator is one of the key members of the team, and enhancing the efficiency of this role through improved operator response provides a critical advantage.

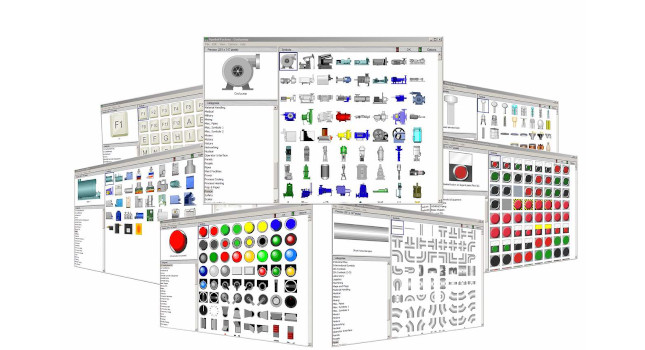

Operators need the ability to reason, plan, and solve problems quickly, and to use a wide set of software tools to present data, collaborate, and automate advanced intelligent analysis. The right tools can provide quick, easy-to-use, and effective decision support needed to understand and troubleshoot both routine and upset conditions. Advanced features such as alarms, historical trending, and predictive analysis are helping operators drive higher value of events and process information, increasing productivity for businesses. The adoption of software technology can drive operational excellence by enabling operators to: leverage analyzed data from many sources; make objective decisions based on complex, real-time information; and understand the system to solve problems quickly and effectively.

With the introduction of decision-making software about 30 years ago, more tasks became automated, and the focus of operators shifted to performing tasks across different systems.

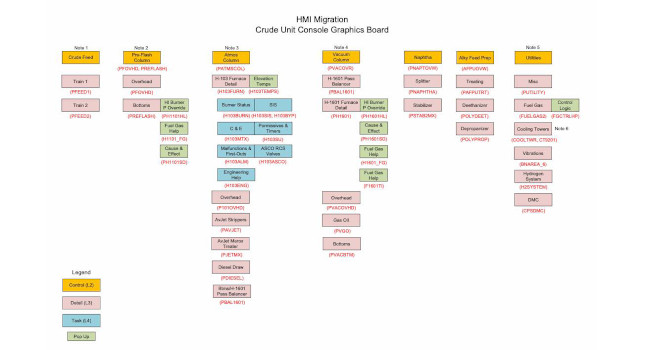

Massive adoption of software tools such as HMI (human machine interface), SCADA (supervisory control and data acquisition), MES (manufacturing execution systems), and MI (manufacturing intelligence) has resulted in significant volumes of data, with more alarms and warnings being produced than ever before—making operators increasingly critical to the team as they provide the first level of interpretation.

Software systems have evolved to provide reliable visualization and control of devices, although there is a significant gap in software tools in terms of the level of intelligence added to the data. Solutions that provide informational and analytical tools offer a key advantage because they can reduce the need for operators to interpret raw data, enabling them to be more intelligent problem solvers.

Driving operator effectiveness and intelligence

Operators need tools that help them engage so they can leverage powerful analytics and intelligence for critical decision making; automated analytics are equivalent to encapsulating the process engineer’s knowledge into the software to enhance operators’ ability to respond to real-time data. They also need the ability to respond to real-time data made available through mobile computing, instant connectivity, and knowledge-sharing software for faster, more focused reactions.

With operators increasingly becoming generalists, the digitization of work processes to encapsulate specific knowledge, as well as to ensure safe and repeatable operations, is key to driving effectiveness. Highly advanced software solutions can help businesses leverage their operators, collectively share vital information, and automatically transform data into information.

Advanced software solutions and platforms contain the features and functionality to drive operator effectiveness and are specifically developed with a focus on how operators interact with the system, enabling more informed decision making.

A look into the future

Systems are now being deployed with heavy input from the operator, moving away from being purely functional data solutions to intelligent, analytical systems. IT and engineering groups are increasingly looking for operator feedback on initiatives and software purchases, and how the system provides value-added information to users—not just data for visibility. There is also increasing importance on collaboration platforms and software that analyze and provide information based on real-life data.

The need to transform data into information is essential as many operators and technicians are nearing retirement age, and consequently, companies are losing “operator knowledge” as these retirees exit the workforce. Capturing this knowledge will help existing operators leverage institutionalized knowledge, decrease the need for training, and ease the learning curve for new operators who will have little to no guidance as they move into roles that require the ability to reason and solve problems through objective decision making.

Future capabilities could include real-time chat, which would enable operators to connect with remote engineering experts on demand and allow them to view what they see on their screens, much like a global social networking site within a corporation. By enabling operators to access experts directly through their consoles, they would be able to leverage the knowledge outside their local operations to quickly solve problems and understand data with ease.

Lastly, the implementation of interoperability standards within software suites is critical to achieving faster rollouts while providing companies with greater flexibility on module selection across vendors. Software vendors no longer require custom coding to play well with others, as standards are continuously being adopted to drive a point-and-click configuration that significantly increases time to value and flexibility for customers. As a result, companies can reduce rollout costs and have the ability to choose the best modules available, regardless of the vendor.

Holistic, scalable software solutions are garnering much attention by businesses because they can add true value to all levels of the organization with specific modules that can be implemented over time—delivering quick, easy-to-use, and effective decision support needed by operators to troubleshoot issues and routine conditions.

Forward-looking businesses that recognize the value of today’s operator have begun adopting advanced software tools to support them as more intelligent problem solvers, significantly increasing productivity and efficiency to gain a competitive advantage.

Bernardo is general manager, automation software for GE Intelligent Platforms.