Heat tracing can be used to heat a variety of products. Understanding the basics of sizing and installing external line tracing will help you apply it effectively.

Often, the temperature of process liquids being transferred through pipelines must be maintained to meet process requirements, prevent thickening and solidification, or simply to protect against freeze-up. This is achieved with jacketed pipes or by attaching one or more tracing lines (carrying a heating medium such as steam or hot water) to the product’s pipeline. In these applications, steam usage may be relatively small, but the tracing system usually is a major component of the steam installation and the source of many problems.

While no single article can address all of the contingencies affecting a steam tracing system, the following guidelines provide an overview of items to consider. Only external tracing is addressed because this is the area most likely to cause difficulties when no existing experience is available. External tracing is simple, and, therefore, inexpensive to install and fulfills the most processes’ needs.

External tracer lines

One or more heat-carrying lines, sized from 0.375 to 1 in. normal bore, are attached to the main product pipe. Heat transfers to the product in three ways: conduction – through direct contact, convection, via currents in the air pocket formed in the insulating jacket, and through radiation. Tracer lines can be constructed of carbon steel, copper or stainless steel. If the product line is constructed of a particular material to accommodate the process fluid, the tracer line material must be selected carefully to avoid electrolytic corrosion at contact points.

For short tracing runs – around short vertical pipes or valves and fittings – small bore copper pipes (perhaps 0.25 in. bore) may be wound around the product lines (figure 1). The layout should be arranged to provide a continuous fall along the tracers. (Note: Wrap around tracers should be avoided on long horizontal lines.) A run of even 100 ft of 6 in. product line will require 500 to 600 ft of wrap-around tracing. In this scenario, the pressure drop along the tracer would be high and the temperature at the end of the line away from the supply would be low. Indeed, the remote end of the tracer probably would contain only condensate, and the water’s temperature would fall as it continued to give up heat.

Clip-on tracers

The simplest form of external tracer is clipped or wired to the product line. Maximum heat flow is achieved when the tracer is in tight contact with the product line; consequently, the securing clips should not be spaced wider than 12 to 18 in. on 03.75 in. tracers; 18 to 24 in. on 0.5 in. tracers; and 24 to 36 in. on 0.75 in. and larger tracers.

The tracer pipes literally can be wired on, but to maintain close contact, 0.5 in. galvanized or stainless steel bands are better. One practical application method is a packing case banding machine. Where racers are carried around bends, three or more bands should be used to ensure that good contact is maintained. Where it is not possible to use bands as on valve bodies often annealed stainless steel 18 gauge wire is an alternative. With either band material, remember to consider any special needs to avoid external corrosion or electrolytic action.

Welded tracers

Where the temperature difference between the tracer and the product is low, the tracer can be welded to the product line. This can be done either with short-run welds or with a continuous weld for maximum heat transfer. Welded tracer sometimes is laid along the top of the pipe instead of the bottom, greatly simplifying installation. Advocates of this method claim that the location does not adversely affect heat transfer rates.

Heat conducting paste

For maximum heat transfer, a heat conducting paste can be used to fill the normal hot air gap (figure 2). The paste can be used with any of the clipping methods, but the surface must be wire-brushed clean before applying the past.

Insulation

If the product being heated is temperature sensitive, it is important to avoid local hot spots on the pipe by introducing a strip of insulation material – fiberglass or mineral wood with packing blocks constructed of inert material to maintain spacing – between the tracer and the product pipe.

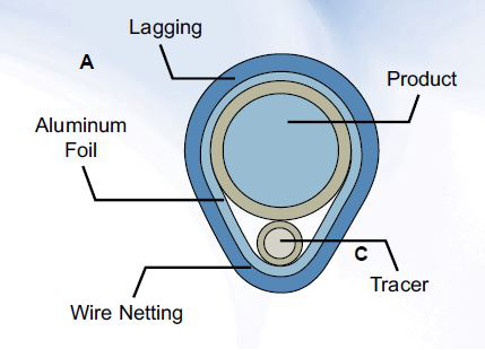

In every installation, insulation should cover both the product line and tracer, but the air space must remain clear. This can be achieved three ways (figure 3)

- Aluminum foil or galvanized steel sheet can be wrapped around the line and tracing; then, insulation is applied over the sheet or foil. Alternatively, small mesh galvanized wire netting can be used instead of metal sheet.

- Sectional insulation preformed to one or two sizes larger than the product main can be used. One disadvantage is this insulation can be easily crushed.

- Preformed sectional insulation designed to cover both product line and tracer can be used. Preformed rigid sectional insulation usually is preferred to plastic material because – rigid insulation retains its thickness and efficiency.

In all cases, the insulation should be finished with waterproof covering: Most insulation is porous, and it is useless as heat-conserving material if it is allowed to absorb water. It also may need to be protected from mechanical damage.

Sizing external tracers

The goal of any steam tracing or jacketing installation is to maintain the line’s contents at a satisfactory working temperature under all conditions of low ambient temperature – with adequate reserve to meet extreme conditions.

On some exposed sites, for example air temperature can be reduced by 4 degrees when 20 mph wind is present. These are circumstances that must be considered when studying the tracer line requirements. Information about prevailing conditions usually can be obtained from the internet or local weather forecast.

External tracer sizing most often is accomplished based on the experience of a given company with a particular process but do not necessarily apply elsewhere. There also are widely differing opinions about layout. One rule of thought states that multiple tracers should be positioned below the product’s center line while another states that it is preferable to space tracers equally around the line.

Then, there are those who will endeavor to size their tracers from 0.375. 0.5, 0.75 or 1 in. or larger pipe. But another school of thought states that because tracers have only minute contact with the product line, much more even heat distribution will result if multiple 0.5 in. tracers are used. If this rule is followed, Table 1 can be used for most average installation requirements. Type A would suffice for most fuel oil applications and for those lines carrying acid, phenol, water and some additional chemicals. But in some cases, spacer tracing (insulation between the product line and the tracing) would be employed.

Steam pressure is important and must be specified according to the product temperature required. For noncritical tracing (Types A and B in Table1), a steam pressure of 50 psi generally would be suitable. For Type C, a higher pressure and hot discharging trap may be required.

Jacketed lines

Ideally, jacketed lines should be constructed in no more than 20 ft lengths with condensate removed from each section. Steam should enter at the highest end so there is a natural fall to the condensate outlet. When it is impractical to trap each length, several sections (up to a combined length of 80 to 100 ft) may be joined in moderate climates. In extremely cold parts of the world, 40 ft should be the maximum. When linking sections, avoid connecting solely through the bottom loop. This can only handle condensate. The standing water impedes the free flow of steam (Table 2).

Although a 0.5 in. condensate outlet usually is adequate, an outlet that is the same size as the steam connection often is used to simplify installation.

Positioning

In horizontal runs, the steam will generally flow parallel to the product line. As far as possible, steam should enter from the high end to allow free flow of the condensate to the low end; it should be self-draining. It is generally considered preferable to center one tracer on the bottom of the line or place two tracers at 30° or three tracers at 45°. Where multiple 0.5 in. tracers are used, they should be arranged in loop fashion on either side of the product line (In vertical lines, the tracers would be spaced uniformly.)

The maximum permissible tracer length depends, to some extent on the size and initial steam pressure, but as a general rule, 0.375 in. tracers should not exceed 60” in length, and the limit for all other sizes should be 150 ft. Bends and low points in the tracer should be avoided.

Expansion

Tracer line expansion often is over looked. Naturally, the steam-heated tracer will tend to expand more than the product line. Where the tracer passes around flanges, the bends are quite adequate to accommodate expansion. But, for long runs of uninterrupted tracer, it is essential to provide for expansion by forming a complete loop in the tracing line. Understanding the components of a steam tracing system is essential for effective installation and operation.